Machine Part 1

(Main part of the Paper Pipe Cutting Machine)

Name:

Rotary Cutting Mechanism

Cutting Shaft:

Four Cutting Shaft with PE tube Cover

Paper Core Feeding: Automatic

After the paper core log automatic fed on the shaft, the shaft with paper core will be rotated to the cutting position and automatically cut,after finished, the cut core will be automatically push out of the shaft.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3Phase 380V 50HZ

-

Power:

-

11KW

-

Dimension(L*W*H):

-

as model

-

Weight:

-

2500 kg

-

Warranty:

-

12 Months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Automation:

-

Fully Automatic

-

Raw material:

-

Paper Core,paper tube and paper pipe

-

PLC Control:

-

Yes

-

Touch Screen:

-

Yes

-

Paper Core Loading:

-

120PCS

-

Cutting Model:

-

Four shaft Rotary Cutting

-

Paper Core Feeding:

-

Automatic

-

Min. Cutting Width:

-

12 mm

-

Max.Width of Core:

-

1200mm

Quick Details

-

Production Capacity:

-

150 pcs/min

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XINWANG

-

Voltage:

-

3Phase 380V 50HZ

-

Power:

-

11KW

-

Dimension(L*W*H):

-

as model

-

Weight:

-

2500 kg

-

Warranty:

-

12 Months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Automation:

-

Fully Automatic

-

Raw material:

-

Paper Core,paper tube and paper pipe

-

PLC Control:

-

Yes

-

Touch Screen:

-

Yes

-

Paper Core Loading:

-

120PCS

-

Cutting Model:

-

Four shaft Rotary Cutting

-

Paper Core Feeding:

-

Automatic

-

Min. Cutting Width:

-

12 mm

-

Max.Width of Core:

-

1200mm

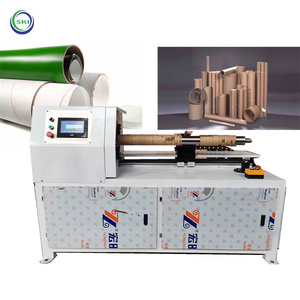

Automatic Paper Core Slitter , Paper Tube Slitting Machine

Product Application

The Automatic Paper Core, paper pipe paper tube Cutting Machine/Slitting Machine is suitable for cutting Paper Core/Paper Tube/Paper Pipe for roll materials core into small widths. Fully automatic cutting with high speed and high efficency.

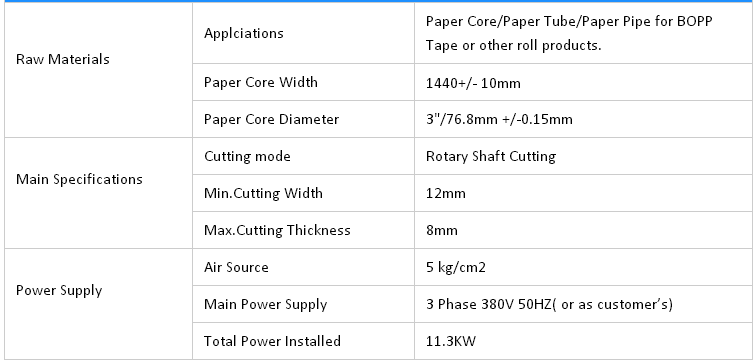

Basic Parameters

Main Features

Application

Specially for 3inches BOPP adheisve tape core cutting.

Suitable for core length of 1200mm +/-10mm, thickness under 5mm.

Description:

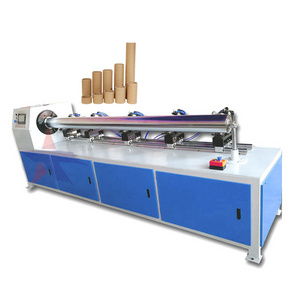

Automatic blanking, automatic paper core loading,automatic cutting, automatic core unloading.

Intelligent servo driving.

High-capacity of paper roll. (120PCs of 1200mm core each time)

Multi-station linkage operation.

Character:

Working-efficency is 5 times of the traditional machine.

Lanor cost just 1/5 of the traditional machine.

Stable performance, running smoothly, high-quality production,less wastage, high-safety factory.

3-Phases Partition speed setting, for filting offcut

Machine Part 2 :

Name:

Paper Core Loader

Loading:

Manually

Loading quantity:

120 pcs

The loader can load 120 pcs paper core log at one time, but you need to put the paper core in the loader manually at one time and then the core will automatically feeding.

Name:

Control Panel

Brand:

Schneider

Control:

PLC control

PLC control with touch screen, which highly increased the operation efficiency and the machine performance.