- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SMAGALL

-

Application:

-

upper, lower limited measurement

-

Ambient Temp:

-

Ambient Temp/-10~300℃

-

Paddle Speed:

-

1r/m of Rotary Paddle Level Switch

-

Medium Density:

-

≥0.2g/cm3(bigger paddle)

-

Output:

-

Switch signal

-

Power Supply:

-

AC220V/DC24V

-

Mounting Mode:

-

Flange mount.;G1.5 in thread

-

Measuring range:

-

40--15000mm

-

IP protection:

-

IP67

-

Customization:

-

Yes

Quick Details

-

Grade:

-

DIY, Industrial

-

Warranty:

-

1 years

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

SMAGALL

-

Application:

-

upper, lower limited measurement

-

Ambient Temp:

-

Ambient Temp/-10~300℃

-

Paddle Speed:

-

1r/m of Rotary Paddle Level Switch

-

Medium Density:

-

≥0.2g/cm3(bigger paddle)

-

Output:

-

Switch signal

-

Power Supply:

-

AC220V/DC24V

-

Mounting Mode:

-

Flange mount.;G1.5 in thread

-

Measuring range:

-

40--15000mm

-

IP protection:

-

IP67

-

Customization:

-

Yes

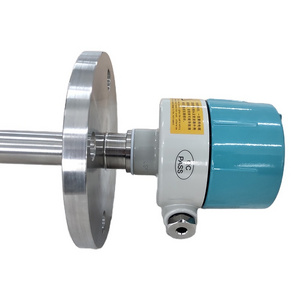

Tuning Fork Level Switch

|

|

Technical Parameters

| Typical application | can be used for most liquids, including coating liquids, aerated liquids and slurries. |

| Fork body material | 316L |

| Fork length | 100mm(can be customized according requirements) |

| Power supply | 24VDC, 220VAC |

| Working temperature | Fork body:-40-130 ℃ Instrument -40-80℃ |

| Medium density | ≥0.7g/cm3 (liquid), ≥0.1g/cm3 (solid) |

| Process pressure | <2.0 MPa |

| Process connection | Thread, flange (optional) |

| Protection level | IP 67 |

| Explosion proof grade | Exd II BT4 (optional) |

| Signal output | SPDT relay output |

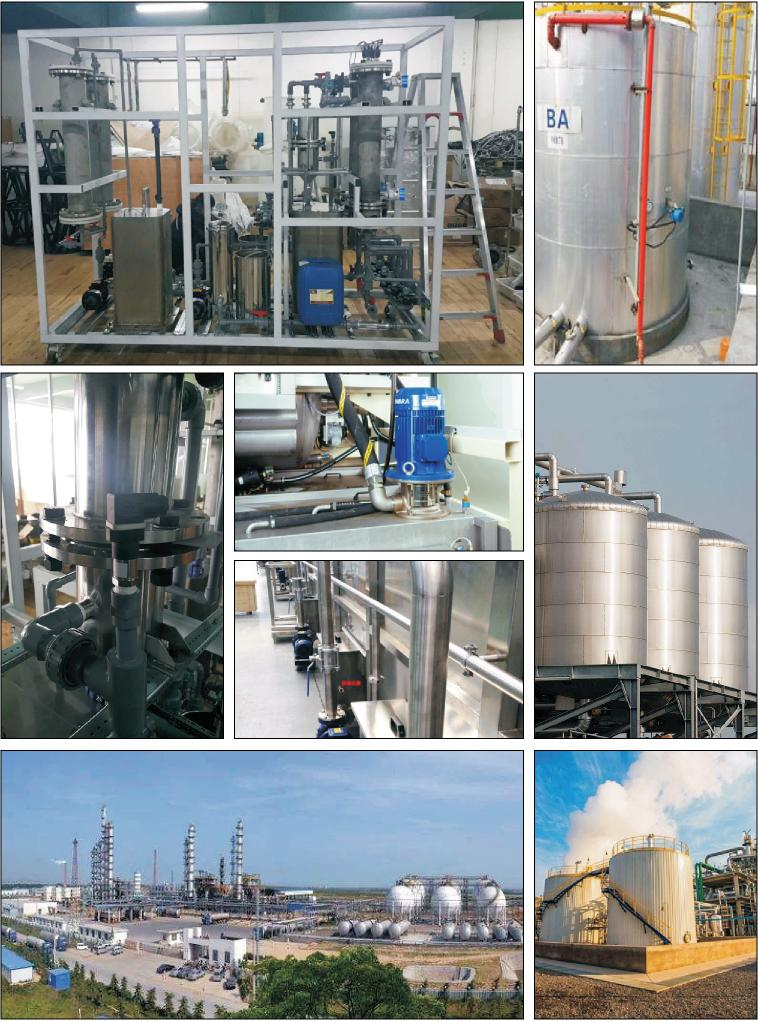

Application

- Water plant: water level detecton of tap water and mineral water;

- Liquid that can generate gas

- Paper mill: pulp, glue, dye level

- Beverage factory/brewery: beer, beer starter, beverage level

- Chemical plant: detect the liquid level of polyester, spandex, waste water, mud, acid, alkali,etc.

- Glass factory: check the level of quartz sand and cullet

- Oil production plant: detect gasoline/oil production liquid level

- Environmental protection: check the level of sewage and wastwater

- Boiler factory: check the water level of the steam drum and the liquid level of other pressure vessels

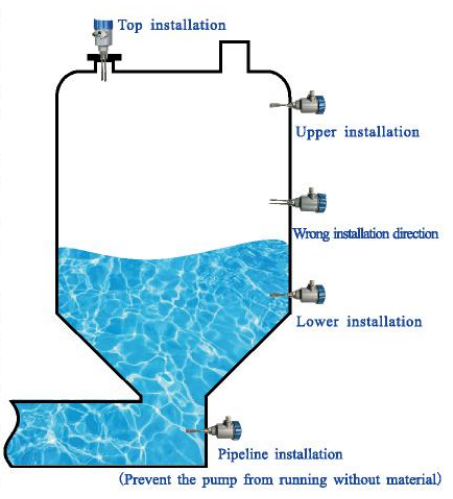

Installation

- The instrument is generally installed vertically with the fork end

downward, horizontally installed or with the fork end inclined downward.

- When the material is mixed with lumps or hard particles, it is recomeended to adopt a vertical or inclined installation method.

- The actual installation is generally dividedinto top installation(high-level monitoring of the medium), side wall installation (high or low-level monitoring of the medium), and pipeline installation (air flow monitoring of the material pump)

Hot Searches