- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

15214*2456*1800(mm)

-

Weight:

-

3000 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380v

-

Power:

-

11.2KW

-

Application:

-

Food Industry

-

Raw material:

-

SUS 304 Stainless Steel

-

Capacity:

-

9000-13500pcs/h

-

Accessories:

-

Import siemens,mitsubishi etc.

-

Operating procedure:

-

Panasonic PLC

-

Advantage:

-

Easy Operation High Performance

-

Shape:

-

Long strip

-

Pre-sales consultation:

-

Guided site selection & installation service

-

After-sales service:

-

Engineer online support and on-site service

-

Package:

-

Wooden box

Quick Details

-

Machinery Capacity:

-

9000-13500pcs/h

-

Brand Name:

-

JUHENG

-

Year:

-

2023

-

Dimension(L*W*H):

-

15214*2456*1800(mm)

-

Weight:

-

3000 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380v

-

Power:

-

11.2KW

-

Application:

-

Food Industry

-

Raw material:

-

SUS 304 Stainless Steel

-

Capacity:

-

9000-13500pcs/h

-

Accessories:

-

Import siemens,mitsubishi etc.

-

Operating procedure:

-

Panasonic PLC

-

Advantage:

-

Easy Operation High Performance

-

Shape:

-

Long strip

-

Pre-sales consultation:

-

Guided site selection & installation service

-

After-sales service:

-

Engineer online support and on-site service

-

Package:

-

Wooden box

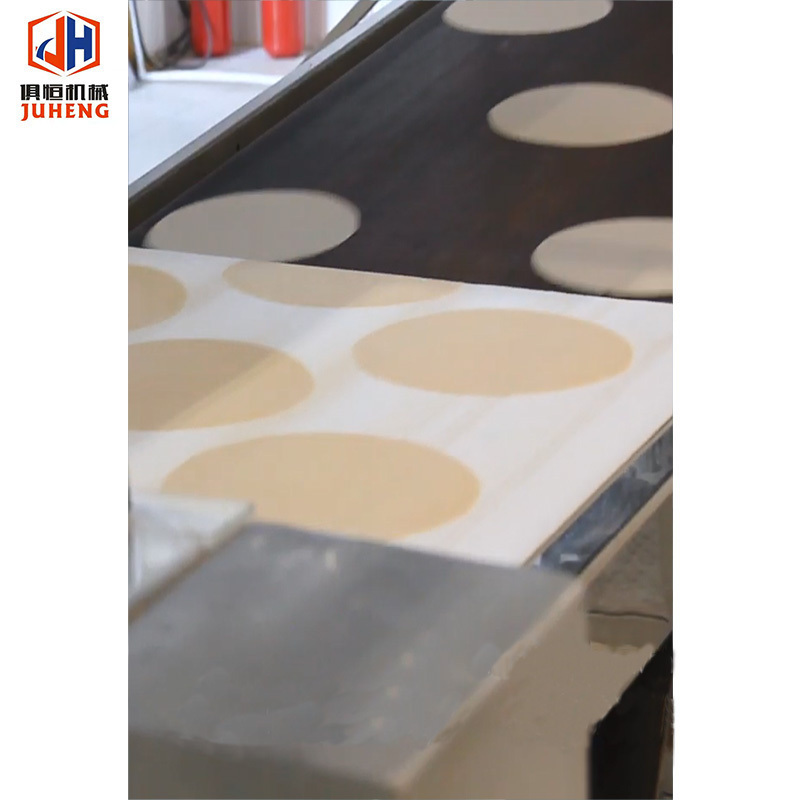

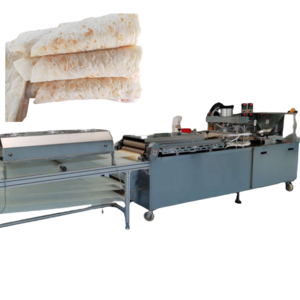

Product Display

|

|

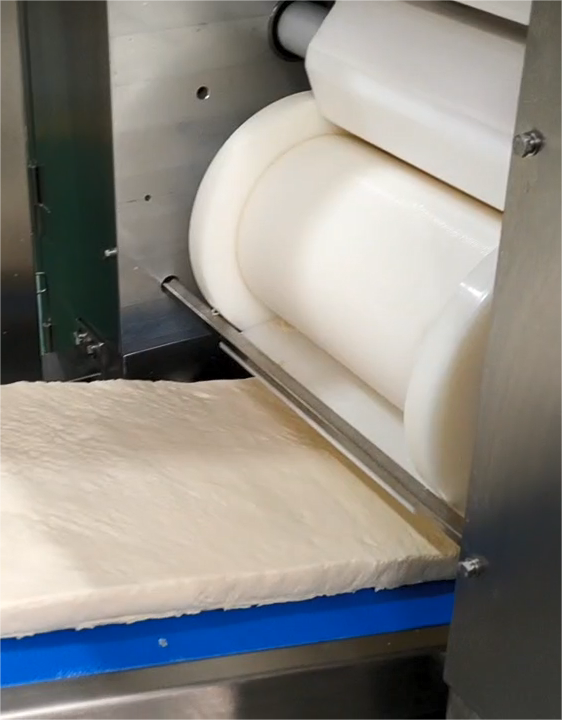

Process

|

Equipment needed

|

|

1

|

dough bulk dividing

|

dough divider

|

|

2

|

dough preliminarily rolling

|

dough arranging machine

|

|

3

|

continuous thinning

|

planetary roller*4

|

|

4

|

dough ribbon stretching

|

dough stretcher

|

|

5

|

moulding

|

moulder

|

|

6

|

conveying

|

conveyor

|

|

7

|

baking

|

oven

|

|

8(optional)

|

water spraying

|

sprayer

|

|

9

|

cooling

|

cooler

|

Introduction

The complete processes of our lavash equipment are:

1)

The dough is

preliminarily rolled, and the dough surface becomes smooth and the thickness becomes

uniform.

2) The continuous thinning/rolling mechanism further processes the dough.

3)

the dough is made into dough ribbon, and the dough ribbon is stretched with a stretching machine.

4)

Stretching and thinning until the thickness is less than 1mm

.

5) Moulder cut the dough ribbon into desired shape and size.

6)

Equip the right oven for baking

.

7) Cooling for packing

.

*We accept customization, please tell us your needs, such as output, bread size, etc., the

more detailed the better. We will do our best to provide you with a satisfactory solution.

Details Images

Hot Searches