- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5500mm*1400mm*800mm

-

Year:

-

2023

-

Power (kW):

-

11 kW

-

Weight (KG):

-

6000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

As customer requirement

-

Shear knife(pcs):

-

40

-

Feed size(mm):

-

1160*760

-

Shear knife:

-

200*20

-

Capacity:

-

800-1500kg/h

-

Power:

-

22*2kw

-

Knife Thickeness:

-

20mm

-

Roller diameter:

-

200MM

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shuguang

-

Voltage:

-

380V,50Hz

-

Dimension(L*W*H):

-

5500mm*1400mm*800mm

-

Year:

-

2023

-

Power (kW):

-

11 kW

-

Weight (KG):

-

6000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

As customer requirement

-

Shear knife(pcs):

-

40

-

Feed size(mm):

-

1160*760

-

Shear knife:

-

200*20

-

Capacity:

-

800-1500kg/h

-

Power:

-

22*2kw

-

Knife Thickeness:

-

20mm

-

Roller diameter:

-

200MM

Competitive Price used tire cutting machine for sale/tire shredder

| Application: |

1.Tire shredder is suitable for shredding solid materials , such as, car tire, truck tire,e-waste,metal,wood,plastic, scrap tires,plastics,paper,etc.

2.It is widely used in industry waste recycling,medical recycling,electronic recycling,municipal solid waste recycling, plastic recycling,tire recycling,paper making industry,etc

3.It is also suitable for crushing the big solid material like television,washing machine,shell of refrigerator,big size pipe,pipe fittings,forklift splint,tyres,packing barrel,vehicle body,aluminum,copper and steel.

| Working Principle: |

1.Material will be deliveried into the feeding chamber

2.There is a blade and pusher on the box. The pusher is used to push the material near the blade.

3.Material is teared,squeezed and cut, small pieces is finished.

4.Small pieces of material is discharged by the Discharge port.

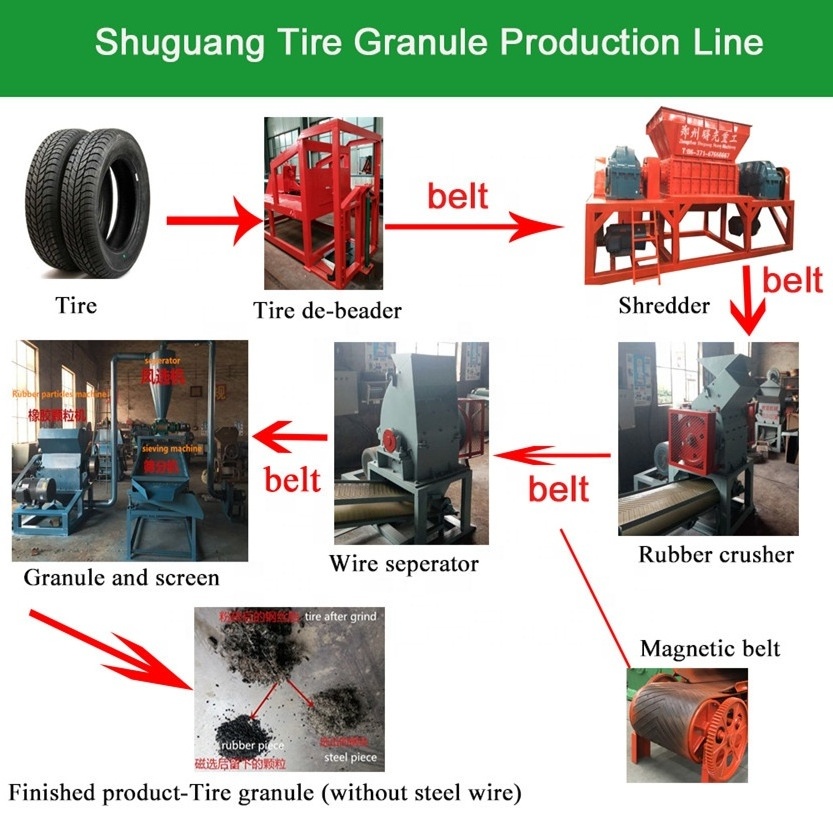

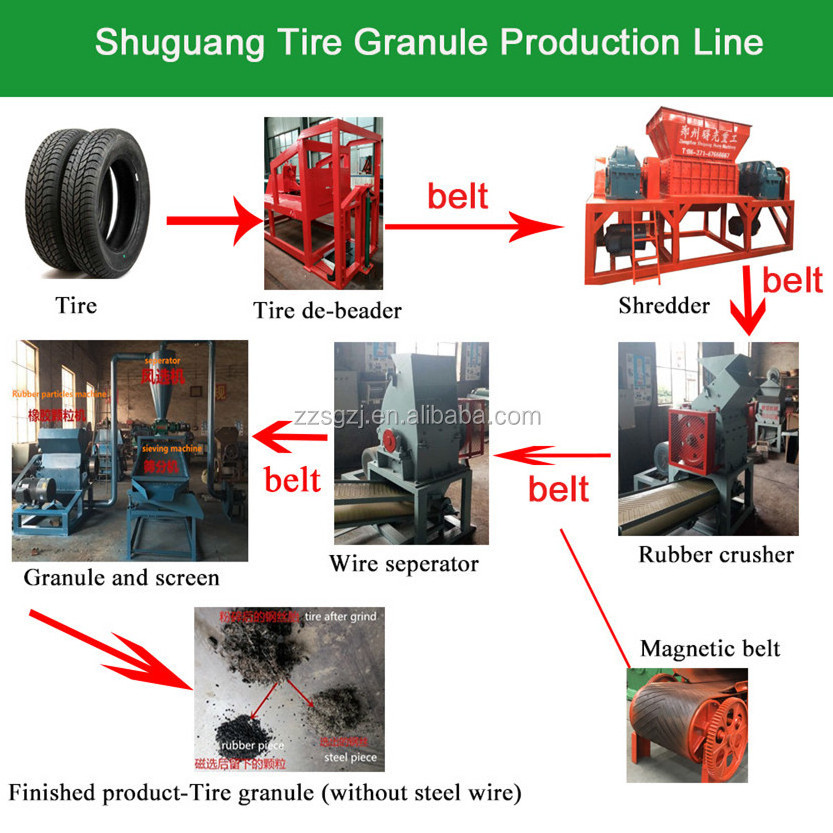

Working principle:

1.First, the steel wire tire decomposing equipment decomposes the steel wire tire into blocks.

2.Then the tire block is broken into (5-10cm) blocks by the tire shredder.

3.After the steel wire separator: the rubber and the steel wire are separated and processed into rubber particles. (10mm-20mm).

4. In the rubber pellet machine: crush the rubber particles to a smaller size (1mm-7mm).

5.After passing through the vibrating screen: sort the rubber particles of different sizes, and send the oversized particles back to the crusher Carry out secondary pulverization,.

6.Then fiber separator: remove foreign matter and fibers, then enter the rubber mill at room temperature for fine grinding,

processed into fine rubber powder with a fineness of 5-80 mesh,

7.Finally bagged after a magnetic separation process Sales.

Equipment can be configured according to actual needs

| 1.Tier de-beader |

Pull out the bead wires inside tires’ side walls completely before cutting and shredding processed.

Structure and principle

1.Before cutting and grinding use steel wire drawing machine, it can protect the blades of tire shredder, prolong the service life of the blade and increase the working efficiency of the shredder ;

2.This model is composed of motor, hydraulic system, steel wire retractor, pull mouth, body;

3.The motor drives hydraulic system and oil cylinder, and steel wire retractor is connected to the cylinder pull rod. The movement of oil pump and oil cylinder makes wire retractor do reciprocating movement.

2.Tire Shredder

After seperated with the steel wire,the tire will be conveyed into shredder machine, the remain tire will be shreded to about 30-50mm pieces size.

3.Rubber crusher

After shreded,the final pieces scarp will be sent into rubber crusher,it will crush the piece into small particles.

Rubber crushing machine is used to crush the rubber from the shredder machine, and the particle size can reach 1mm after crushing.

For the rubber with different shape and thickness, the machine adopts specific cutter body structure, high strength solid shaft and cutter frame which makes crushing efficiency and capacity increase obviously.

4.Seperator machine

The small particles through wire sepatate machine,it will seperate the rubber and residuary steel wire.

This machine can process tire rubber block with the steel wire into rubber granule and separate the steel wire out from rubber with the steel wire, Due to the special design of moving and fixed blades, the machine is high efficient and the blade is strong rigidity, high wear resistance and long service life;

Humanized design: more safety, easy operation and maintenance.

5.Rubber granule and screen

Through belt conveyor which with magnetic roller,wire steel particle will be collected,the rubber

will come into rubber granule machine and make it to smaller partical size,then will get the expected size particle by the screen machine.

6.Magnetic roller

Breif introduction of tire recycling machine production line

| Spare Parts: |

| Company: |

Zhengzhou Shuguang Heavy Machinery Co.,Ltd is a professional supplier of tire shredder in Zhengzhou city, Henan province,China, we can provide various types of shredders for you. If you're interested in our products, please call me freely.

| Related Products |

| Metal Shredder | Plastic Shredder | Paper Shredder |

If you are looking for this machine,please contact us now!please click the following contact to send us email or chat online!