- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

2800 KG

-

Max. working width:

-

400mm

-

Min. working length:

-

300mm

-

Max.working thickness:

-

70mm

-

Working pressure:

-

0.6-0.8Mpa

-

total power:

-

63kw

-

size:

-

33000*1800*2400mm

Quick Details

-

Place of Origin:

-

China

-

Machine Type:

-

painting machine

-

Marketing Type:

-

Hot Product 2022

-

Weight (KG):

-

2800 KG

-

Max. working width:

-

400mm

-

Min. working length:

-

300mm

-

Max.working thickness:

-

70mm

-

Working pressure:

-

0.6-0.8Mpa

-

total power:

-

63kw

-

size:

-

33000*1800*2400mm

Product Description

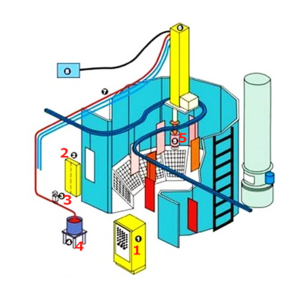

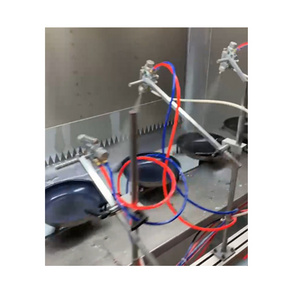

Automatic paint sprayer

Suitable for continuously spraying the top surface and 2 sides of profile work pieces,such as door frames,picture frames,furniture fittings,skirting board,flooring,plastic steel profile,wood plastic steel,etc.Paint can be sprayed such as PU,NC,UV,Water Based Paint,fluorocarbon paint etc.

Performance characteristics:

-Belt type and roller type conveying, high efficiency automatic painting machine is used for high-quality spraying under the condition of high-speed feeding;

-Photoelectric induction system is used to detect the length of incoming workpiece to control the time and range of painting.

-The equipment inside the spray booth is equipped with fire-proof lighting system.

-The humanized graphical interface facilitates the input of various working parameters and equipment parameters;

-The exquisite appearance and internal processing structure make it easy to visit;

Performance characteristics:

-Belt type and roller type conveying, high efficiency automatic painting machine is used for high-quality spraying under the condition of high-speed feeding;

-Photoelectric induction system is used to detect the length of incoming workpiece to control the time and range of painting.

-The equipment inside the spray booth is equipped with fire-proof lighting system.

-The humanized graphical interface facilitates the input of various working parameters and equipment parameters;

-The exquisite appearance and internal processing structure make it easy to visit;

|

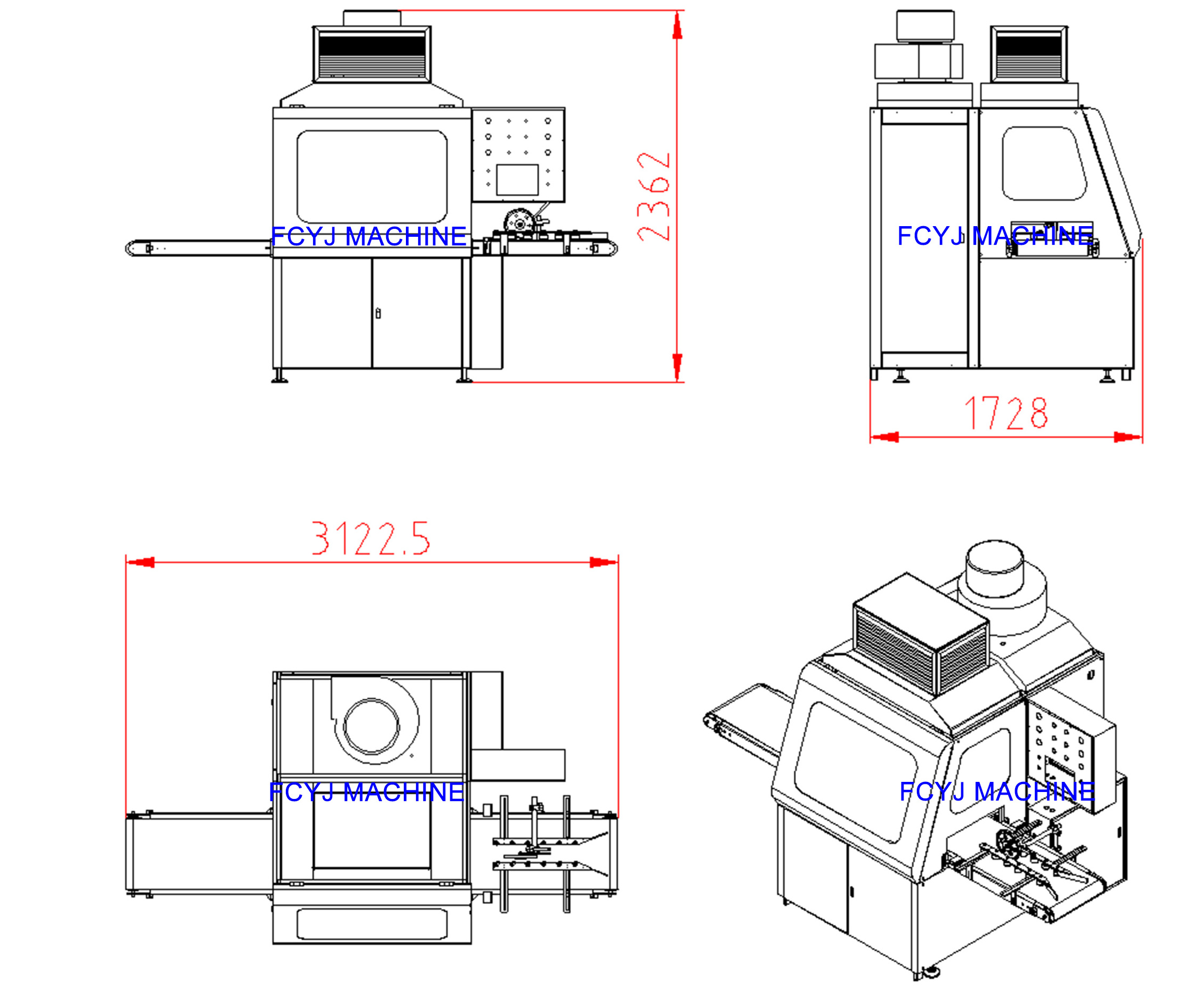

Processing length

|

≥300mm

|

Processing width

|

≤400mm

|

|

Processing thickness

|

5-70mm

|

air pressure

|

0.6mpa

|

|

Conveying speed

|

0-12M/min,adjustable

|

power

|

2.3kw

|

|

Exhaust fan

|

1.5kw

|

inverter

|

VFD-0.75Kw

|

|

Conveying motor

|

0.75kw,Explosion-Proof Motor

|

photoelectricity

|

OMRON

|

|

Diaphragm pump

|

Double diaphragm pump*2sets

|

Spray gun

|

W-71*6sets

|

|

Voltage

|

380v 3phase 50hz

|

size

|

3122*1728*2362mm

|

Belt conveyor

It is applicable to the conveying of long workpieces such as door frame line, picture frame, furniture accessories, skirting line, plastic steel and wood plastic line, etc. when they are connected together.

Performance characteristics:

-It is suitable for conveying large plates and workpieces of different sizes

-All electrical controls are in the electric cabinet, which is easy to operate

-It can be used alone or installed in the whole production line to transport workpieces and transport and connect different equipment

-Optional guide mechanism for more convenient operation.

Performance characteristics:

-It is suitable for conveying large plates and workpieces of different sizes

-All electrical controls are in the electric cabinet, which is easy to operate

-It can be used alone or installed in the whole production line to transport workpieces and transport and connect different equipment

-Optional guide mechanism for more convenient operation.

|

Processing length

|

≥300mm

|

Processing width

|

≤400mm

|

|

power

|

0.75Kw

|

Conveying speed

|

0-12M/min,adjustable

|

|

size

|

3000*850*885mm

|

Conveying motor

|

CH32-750-50S

|

|

inverter

|

VFD-0.75Kw

|

Conveyor belt

|

PVC green-445*6030

|

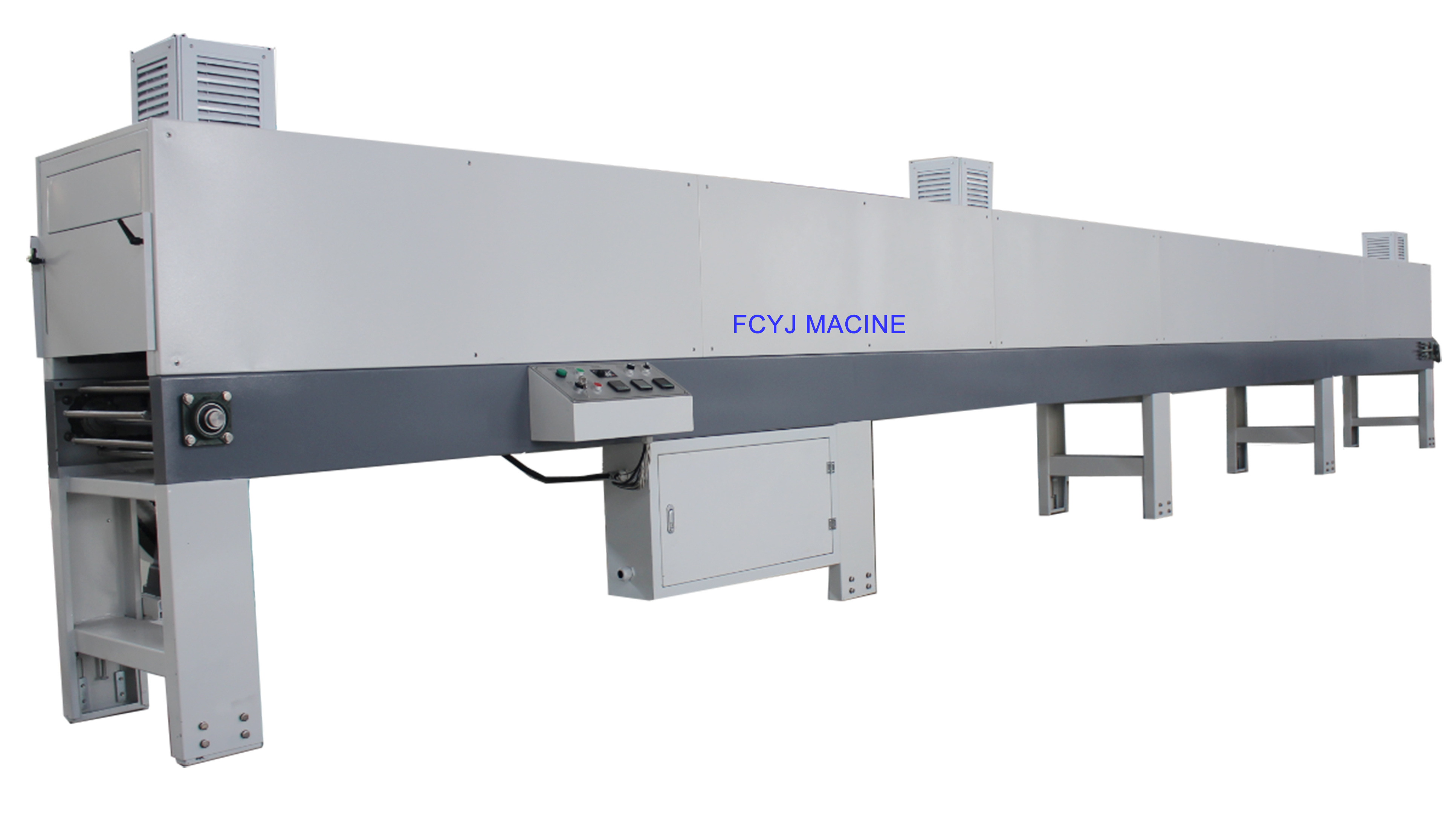

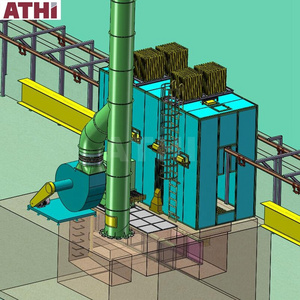

Dryer

It is applicable to the heating, leveling and drying of long workpieces such as door frame lines, picture frames, furniture accessories, skirting lines, plastic steel and wood plastic lines after they are coated with UV, PU, NC, AC, water-based paint, epoxy paint and fluorocarbon paint.

Performance characteristics:

-The unique high-precision heating technology and centrifugal fan circulating heat energy technology are combined to heat the paint film on the surface of the painted workpiece in a very short time, so that the paint on the surface of the workpiece can be dried quickly.

-Accelerate the volatilization of paint thinner and take away volatile gas, especially suitable for the heating and drying of water-based paint;

-It can automatically detect the temperature and recycle the mixed air flow to save energy;

-The exquisite appearance and internal processing structure make it easy to visit;

-The whole machine adopts full insulation technology to save energy to the greatest extent

Performance characteristics:

-The unique high-precision heating technology and centrifugal fan circulating heat energy technology are combined to heat the paint film on the surface of the painted workpiece in a very short time, so that the paint on the surface of the workpiece can be dried quickly.

-Accelerate the volatilization of paint thinner and take away volatile gas, especially suitable for the heating and drying of water-based paint;

-It can automatically detect the temperature and recycle the mixed air flow to save energy;

-The exquisite appearance and internal processing structure make it easy to visit;

-The whole machine adopts full insulation technology to save energy to the greatest extent

|

Processing length

|

≥300mm

|

Processing width

|

≤400mm

|

|

Processing thickness

|

5-70mm

|

power

|

11kw

|

|

Heating mode

|

0.5Kw*18, quartz heating tubes

|

Conveying speed

|

0-12M/min, adjustable

|

|

size

|

10000*925*1550mm

|

Conveying motor

|

CH32-750-50-S

|

|

Fan

|

DS150-51ABHL*1set + CY125*1set

|

inverter

|

VFD-0.75w

|

UV curing machine .

This machine is designed for drying solid color primer, transparent color trimming primer, transparent primer, topcoat, etc. it is used for instant curing of the paint film after UV coating, assembly line production, improving production efficiency, reducing manual operation, six groups of light source configuration, and also for semi dry or full dry action of various properties of UV curing paint. The required gallium lamp and mercury lamp can be added according to customer requirements.

Performance characteristics:

-The chassis of the machine is of integrated design, with a central heat sink for more adequate heat dissipation.

-The design inside the lamp box is ingenious, the lamp tube height can be adjusted, and the disassembly and assembly are convenient.

-Chain type thickened stainless steel pipes are used for conveying, with a spacing of 50mm.

-Six groups of lamps are guaranteed for 800H, and the service time limit can be displayed on the panel.

-Aluminum control panel is adopted.

-Each group of lamps is controlled independently, and each group of lamps can adjust the strong light/weak light control according to the paint demand.

Performance characteristics:

-The chassis of the machine is of integrated design, with a central heat sink for more adequate heat dissipation.

-The design inside the lamp box is ingenious, the lamp tube height can be adjusted, and the disassembly and assembly are convenient.

-Chain type thickened stainless steel pipes are used for conveying, with a spacing of 50mm.

-Six groups of lamps are guaranteed for 800H, and the service time limit can be displayed on the panel.

-Aluminum control panel is adopted.

-Each group of lamps is controlled independently, and each group of lamps can adjust the strong light/weak light control according to the paint demand.

|

Processing length

|

≥300mm

|

Processing width

|

≤400mm

|

|

Processing thickness

|

5-70mm

|

power

|

37kw

|

|

Conveying speed

|

0-12M/min,adjustable

|

size

|

3100*1300*1824mm

|

|

Conveying motor

|

CH32-750-30-S

|

Fan

|

11sets

|

Customer Feedback

Our Advantages

Pre-sale services:

Provide the free consultation of the equipment .

Provide the standard device and the flow chart.

According to the clients' special requirement, offering the reasonable plan and free design helping to select the equipment.

Welcome to visit our factory.

Services during the sales:

Inspect the machine before leaving the factory.

Oversea install and debug the equipment.

Train the first-line operator.

After sale services:

24 hours online service.

Provide the VIDEO with Install and debug the equipment.

Provide technical exchanging.

Provide the free consultation of the equipment .

Provide the standard device and the flow chart.

According to the clients' special requirement, offering the reasonable plan and free design helping to select the equipment.

Welcome to visit our factory.

Services during the sales:

Inspect the machine before leaving the factory.

Oversea install and debug the equipment.

Train the first-line operator.

After sale services:

24 hours online service.

Provide the VIDEO with Install and debug the equipment.

Provide technical exchanging.

Hot Searches