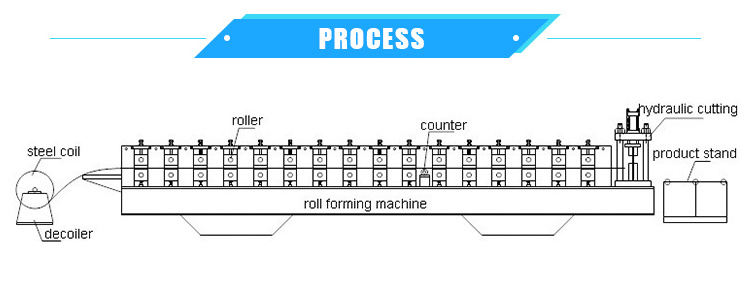

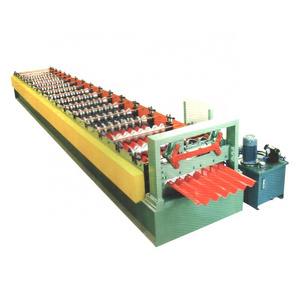

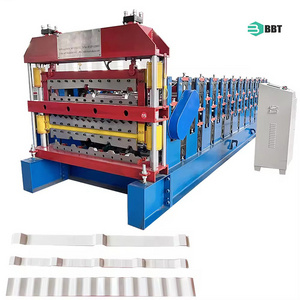

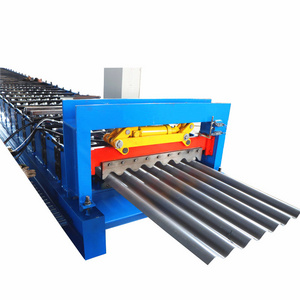

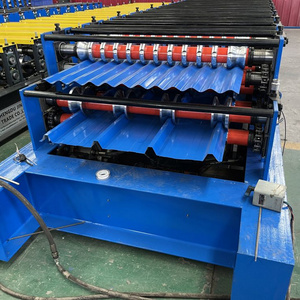

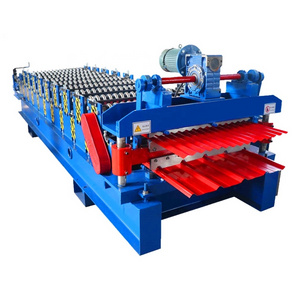

Metropole aluminium roof tile roll forming machine is a kind of Metal Roll Forming Machine . Because of its shape is like the metropole , in Nigeria , people call it metropole roll forming machine .

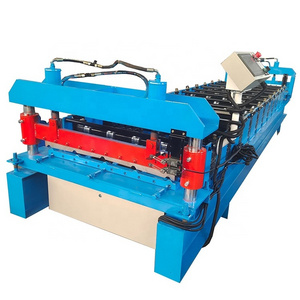

Compared with the IBR roof roll forming machine , it has a hydraulic press part which is used to make the metropole type . For this Roof And Wall Panel Roll Forming Machine , there is a front cutting .

When you want to change the coil , you can cut it directly by the front cutting . To imporve the quality of the machine , we have updated many details of the machine , for example the oil tube .

Compared with the IBR roof roll forming machine , it has a hydraulic press part which is used to make the metropole type . For this Roof And Wall Panel Roll Forming Machine , there is a front cutting .

When you want to change the coil , you can cut it directly by the front cutting . To imporve the quality of the machine , we have updated many details of the machine , for example the oil tube .