- Product Details

- {{item.text}}

Quick Details

-

Design software:

-

PROE/UG/CAD

-

Mould life:

-

500 000--3 000 000 shots

-

Surface treatment:

-

Matte, High glossy polishing

-

Runner:

-

Cold/Hot

-

Material:

-

PP,ABS,PS,PC,PA66,HIPS,PMMA

Quick Details

-

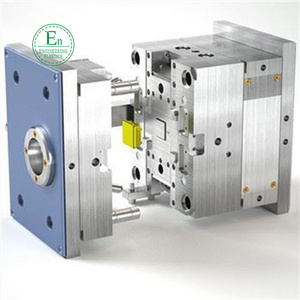

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Mould material:

-

P20/718/2738/2311/2344/S136

-

Design software:

-

PROE/UG/CAD

-

Mould life:

-

500 000--3 000 000 shots

-

Surface treatment:

-

Matte, High glossy polishing

-

Runner:

-

Cold/Hot

-

Material:

-

PP,ABS,PS,PC,PA66,HIPS,PMMA

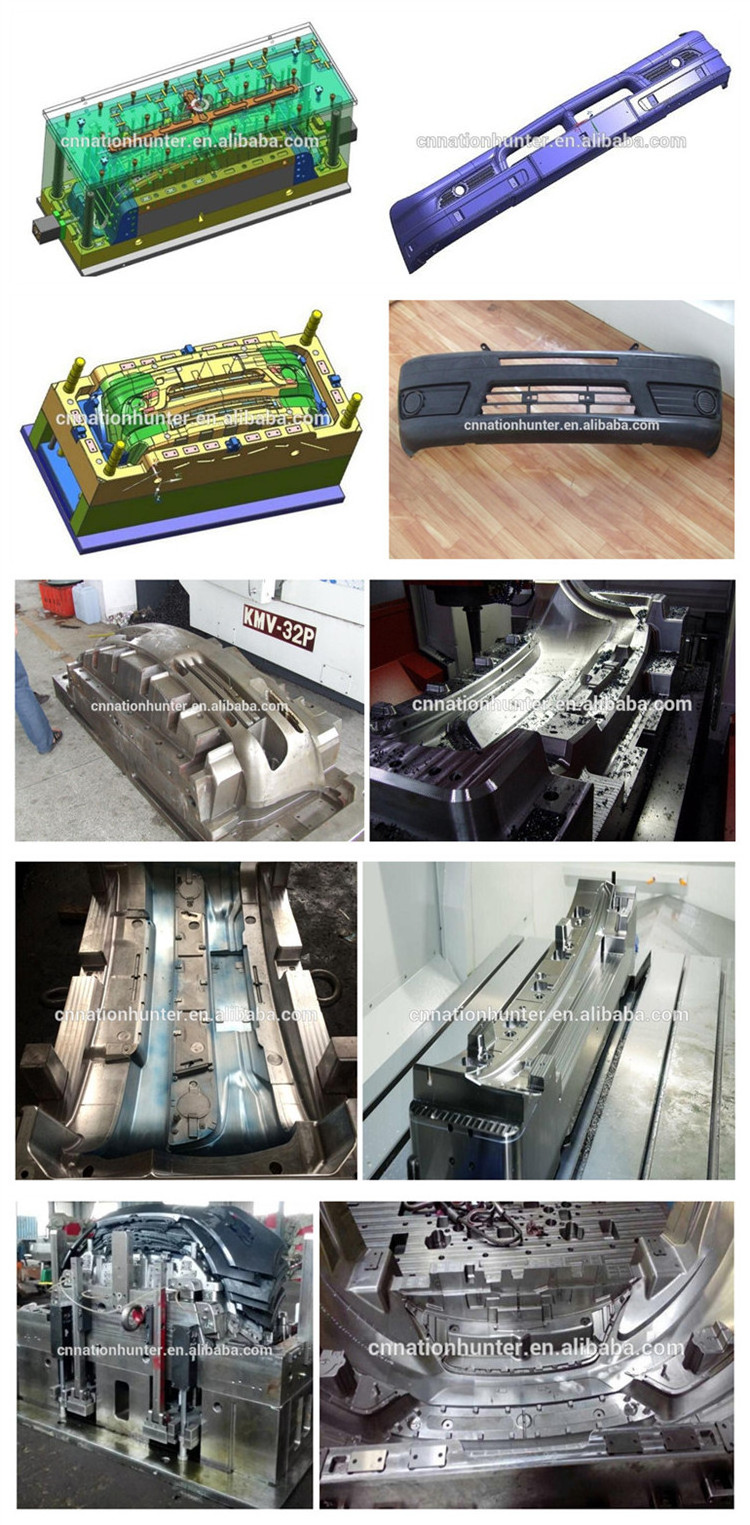

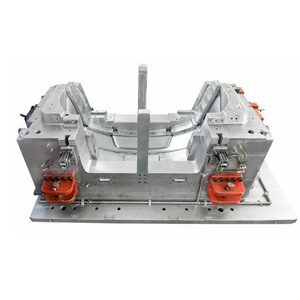

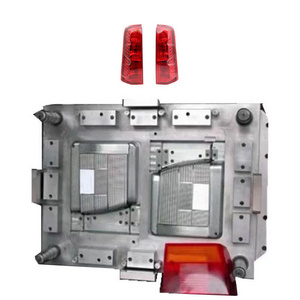

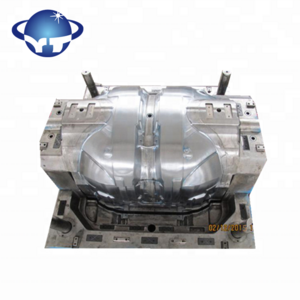

We are professional in making automotive moulds,such as head/rear light mould,car door mould,grille mould,car bumper mould,etc..Welcome to enquiry.

|

Plastic |

PP ,ABS,PC,HIPS,PMMA,POM,PA66+GFR |

|

Cavity & Core |

P20,718,2311,2344,2738,H13,SKD61,SKD11,2316,S136 |

|

Mold base |

L KM,Standard,factory standard |

|

Nos of Cavity |

According to customers’ requirements |

|

Treatment of hardening |

Nitridation, HRC 42-45 |

|

Treatment of hardening |

Vacuum hardening, HRC 48-55 |

|

Mould Accessories |

DME/HASCO Standar d |

|

Cooling |

Perfect water cooling system |

|

Surface finish |

Refer to sample or customers ’ requirements |

|

Molding life |

500 000- 3 00 0 000 cycles |

|

Runner |

Cold or Hot |

|

Delivery time |

35-60 days |

|

Packing |

Ply wood case |