- Product Details

- {{item.text}}

Quick Details

-

Warranty of core components:

-

24 months

-

Voltage:

-

Customer optional

-

Dimension(L*W*H):

-

2261*1495*2245mm

-

Power (kW):

-

3

-

Weight (KG):

-

3000 KG

-

Product Name:

-

Vertical Slotting Machine

-

Name:

-

Slot Cutting Machine

-

After Warranty Service:

-

Video Technical Support

-

Model:

-

B5020 /B5032

-

Type:

-

Slotter

-

Keyword:

-

Heavy Duty Vertical Slotting Machine

-

Color:

-

Customer optional

-

Function:

-

Cutting Metal

-

Application:

-

Metal Cutting Machine

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

CHN

-

Brand Name:

-

classic

-

Marketing Type:

-

New Product 2022

-

Warranty of core components:

-

24 months

-

Voltage:

-

Customer optional

-

Dimension(L*W*H):

-

2261*1495*2245mm

-

Power (kW):

-

3

-

Weight (KG):

-

3000 KG

-

Product Name:

-

Vertical Slotting Machine

-

Name:

-

Slot Cutting Machine

-

After Warranty Service:

-

Video Technical Support

-

Model:

-

B5020 /B5032

-

Type:

-

Slotter

-

Keyword:

-

Heavy Duty Vertical Slotting Machine

-

Color:

-

Customer optional

-

Function:

-

Cutting Metal

-

Application:

-

Metal Cutting Machine

-

Certification:

-

CE ISO

Products Description

Product Application

1. This machine be used for interpolation plane, forming surface and Keyway Etc. And can insert the inclination in the 10° Mold and other within the scope of etc. work matter,,

2. Enterprise suitable for single or small batch production.

1. This machine be used for interpolation plane, forming surface and Keyway Etc. And can insert the inclination in the 10° Mold and other within the scope of etc. work matter,,

2. Enterprise suitable for single or small batch production.

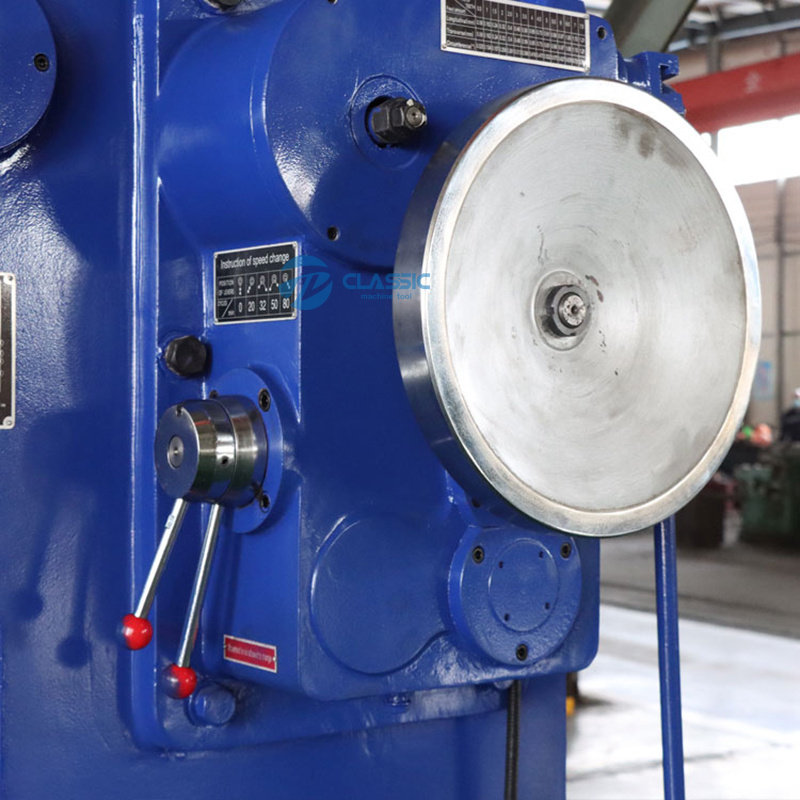

The main performance characteristics:

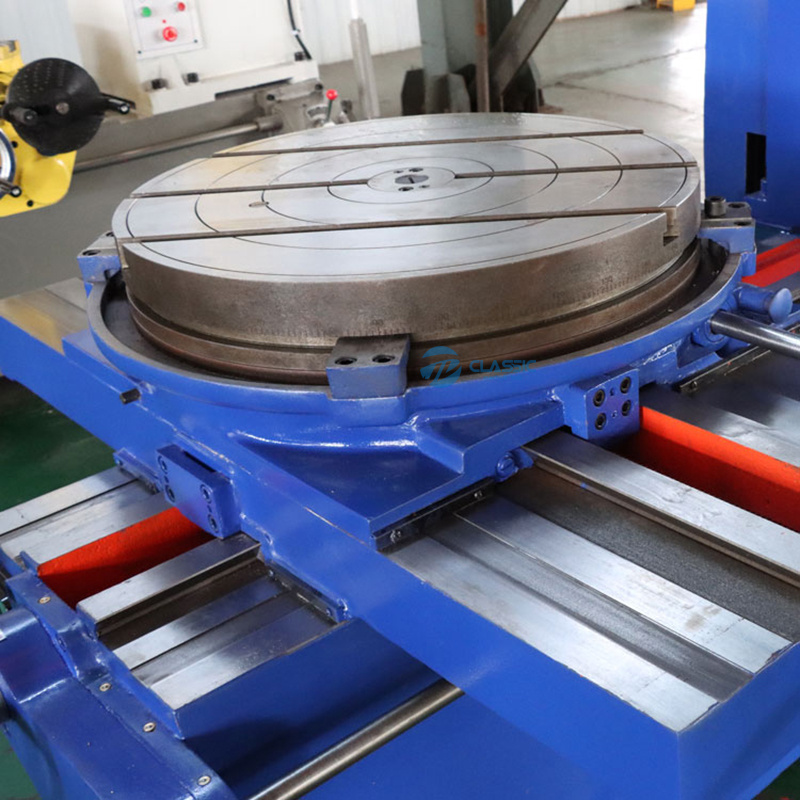

1.The working table of the machine tool is provided with three different directions of feed (longitudinal, horizontal and rotary),therefore work object go through once clamping, Several surfaces in the machine tool machining

2.Hydraulic transmission mechanism with sliding pillow reciprocating motion and hydraulic feed device for working table.

3.The sliding pillow has the same speed in every stroke, and the movement speed of the ram and the working table can be adjusted continuously.

4.Hydraulic control table have ram commutation oil for oil reversing mechanism, In addition to hydraulic and manual feed outer, Even there single motor drive vertical, horizontal and rotary fast moving.

5.Use hydraulic feed the slotting machine, Is when the work is over turning back instantaneous feed, Therefore be better than mechanical slotting machine used drum wheel feed.

Product main technical parameters:

1.The working table of the machine tool is provided with three different directions of feed (longitudinal, horizontal and rotary),therefore work object go through once clamping, Several surfaces in the machine tool machining

2.Hydraulic transmission mechanism with sliding pillow reciprocating motion and hydraulic feed device for working table.

3.The sliding pillow has the same speed in every stroke, and the movement speed of the ram and the working table can be adjusted continuously.

4.Hydraulic control table have ram commutation oil for oil reversing mechanism, In addition to hydraulic and manual feed outer, Even there single motor drive vertical, horizontal and rotary fast moving.

5.Use hydraulic feed the slotting machine, Is when the work is over turning back instantaneous feed, Therefore be better than mechanical slotting machine used drum wheel feed.

Product main technical parameters:

|

Specification

|

Unit

|

B5032

|

B5020

|

|

Max. stroke of RAM

|

mm

|

340

|

220

|

|

Ram maximum slotting length

|

mm

|

320

|

200

|

|

Ram motion frequency

|

times/min

|

20.32.50.80

|

32.50.80.125

|

|

Ram tilt angle

|

°

|

0-8

|

0-8

|

|

Ram vertical adjustment distance

|

mm

|

315

|

230

|

|

Cutter head bearing surface to the distance between the forearm bed

|

mm

|

600

|

485

|

|

Table Diameter

|

mm

|

630

|

500

|

|

The distance between the lower end of the sliding frame to work table

|

mm

|

490

|

320

|

|

Max. longitudinal moving distance of working table

|

mm

|

630

|

500

|

|

Max. transverse moving distance of working table

|

mm

|

560

|

500

|

|

Table maximum rotation angle

|

°

|

360

|

360

|

|

Vertical and horizontal table power feed range

|

mm

|

0.08-1.21

|

0.08-1.21

|

|

Table rotary feed range

|

mm

|

0.052-0.783

|

0.052-0.783

|

|

Motor power

|

kw

|

4

|

3

|

|

Motor speed

|

r/min

|

960

|

1430

|

|

Machine weight

|

kg

|

3000

|

2200

|

|

Outline dimension

|

mm

|

2261*1495*2245

|

1916*1305*1995

|

Detailed Images

Details Display

Recommend Products

Company Introduction

Packing&Shipping

FAQ

1. What is the payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight . When we receive the advance payment, we will start to make production.when the machine is ready , we will take pictures to you.after we got your balance payment. we will send the machine to you.

2.

What CNC system do you use?

A: FANUC, SIEMENS, MISTSUBISHI, LNC,SYNETC,GSK,etc. It depends on your choice.

3.How can I choose the most suitable machines ?

A: Please let us know your machining demand or machine size ,we can choose the best model for you ,

or you can choose the exact model by yourself. You can also send us the products drawing ,we will choose the most suitable machines for you .

or you can choose the exact model by yourself. You can also send us the products drawing ,we will choose the most suitable machines for you .

4. What is your trade terms?

A : FOB, CFR,CIF or others terms are all acceptable.

5. What is your minimum order quantity and warranty?

A: MOQ is one set, and warranty is one year.but we will offer lifetime service for machine.

6. What is the package of the machines?

A: The machines standard packed by iron pallets with plastic films

Contact Us

Hot Searches