- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.5%

-

Voltage:

-

220V/380V.50/60HZ(Can be customized)

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sunshine machinery

-

Dimension(L*W*H):

-

3000*1300*2200mm

-

Weight:

-

1300 KG

-

Max Capacity:

-

60-1200BPH

-

Filling Heads:

-

1-8 Heads

-

Filling range:

-

4-50KG/200-1000KG

-

Bottle type:

-

PET Glass Metal Bottle

-

Model:

-

YG-CZ

-

Material:

-

SUS304/316

-

Usage:

-

Liquid Packaging

-

Transport packaging:

-

Export Standard Packages

-

After-sales Service Provided::

-

ngineers available to service machinery overseas

-

Marketing Type:

-

New Product 2020

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 6000BPH, 400BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

-

Packaging Material:

-

Plastic, Metal, Glass, Wood

-

Filling Material:

-

Milk, Water, Oil, Juice, Other

-

Filling Accuracy:

-

±0.5%

-

Voltage:

-

220V/380V.50/60HZ(Can be customized)

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sunshine machinery

-

Dimension(L*W*H):

-

3000*1300*2200mm

-

Weight:

-

1300 KG

-

Max Capacity:

-

60-1200BPH

-

Filling Heads:

-

1-8 Heads

-

Filling range:

-

4-50KG/200-1000KG

-

Bottle type:

-

PET Glass Metal Bottle

-

Model:

-

YG-CZ

-

Material:

-

SUS304/316

-

Usage:

-

Liquid Packaging

-

Transport packaging:

-

Export Standard Packages

-

After-sales Service Provided::

-

ngineers available to service machinery overseas

-

Marketing Type:

-

New Product 2020

Fully Automatic Weighting Type large barrel weighing drum filling machine

This type machine is used for 4kg -30 kg,liquid filling.It can finish a series of operations automatically, such as bottle inlet, weight filling,and bottle outlet.Especially for edible oil and lube oil.Tt is a nice choice for foodstuff and chemical industries.

1.This machine adopt PLC control,touch screen control panel,convenient to adjust.

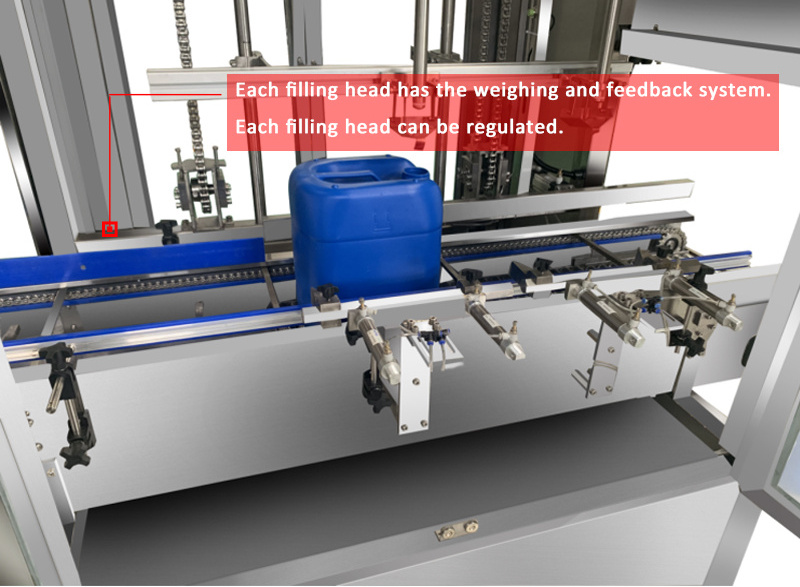

2.Each filling head has the weight and feedback system. Each filling head can be regulated.

3.Photoelectric sensor, approximate switch and other electric elements are the international famous brand. No container no filling. The main host can trigger the alarm if there is any container blocked.

4.Submerged filling makes it possible to reduce form. It is suitable for various kinds of filling products.

5.The whole machine meets GMP standard. It is easy to disassemble clean and maintain, and the parts which contact with the filling products are made of high quality stainless steel. The whole machine is safe, environmental, sanitary, adapts to various kinds of working places.

|

Type

|

Suitable bottles

|

Capacity

|

Machine Size

|

Power

|

Power supply

|

Precise

|

|

2 Heads

|

length:160-3600mm

width:100-300mm height:250-500mm neck diameter:≥Φ40mm (can be customized) |

30kg:200BPH

|

2000*1700*2300mm

|

2kw

|

AC220/380V

50/60Hz |

≤±0.5%

|

|

4 Heads

|

|

30kg:350BPH

|

2500*1700*2300mm

|

2kw

|

|

|

|

6 Heads

|

|

30kg:520BPH

|

3500*1700*2300mm

|

2kw

|

|

|

|

8 Heads

|

|

30kg:600BPH

|

4500*1700*2300mm

|

2.5kw

|

|

|

NO.1

This Machine adopts PLC control,we can operation on the touch screen ,The adjustment is very convenient.

NO.2

This machine is easy to disassemble to clean and maintain,The machine parts which contact with material are made of 304/316L stainless steel.

NO.3

Under the roller conveyor of each filling nozzles,we have German weighing module,it can Real-time feedback weight of the filling liquid and control by PLC to get higher filling accuracy.

100-300kg weighing filling machine

This machine is mainly designed for the intelligent packaging system of 100-300 KG liquid barrels,

the main filling parts use stainless steel environmental frame,tempered glass door. When the machine is filling , it is totally enclosed.On the top,it has the air outlet,it can control air emission.

1.The whole line finish the process of barrel

incoming,barrel distinguish, aiming, falling down.And slowly rising according to the filling quantity add,to prevent the bubble.

2.After the filling automatically out of barrel, it is put the caps around the barrel outlet, through the pneumatic capping head screw.After the whole process ending, through the forklift or human handling of materials.

3.This machine uses PLC to control, touch screen operation.It has characteristics like convenient operation, high efficiency,wide range of application.

4.This machine electric equipment control part is made by PLC, adjust speed channel,it had strong control ability, high automatically.

5.It has function of no barrel no filling, no aiming to barrel outlet no filling,which avoid material waste and pollution.

|

Product Name

|

Barrel weighing filling machine (100-300kg)

|

|

Power supply

|

AC380V 50HZ

|

|

Production capacity

|

≥60 barrel/H

|

|

Type

|

1-2 Heads

|

|

Working temperature

|

-10℃--50℃

|

|

Working humidity

|

<95℃

|

|

Machine Size

|

200*2300*3000mm

|

|

Container injection port diameter

|

≥50mm

|

|

neck diameter

|

Φ500mm~Φ700mm

|

|

Precise

|

≤-0.1%

|

|

Power

|

2.5kw

|

|

Weight

|

1600kg

|

200-1000kg weighing filling machine

1.The forklift moves the pallets and empty barrels to the conveying platform, presses the [Into barrel] button, and the empty barrels are sent to the weighing platform. The operator pushes the rocker arm so that the filling nozzle is directly above the barrel mouth.

2.The operator presses the [Start] button.

3.The filling head is automatically inserted into the barrel, and the tare is automatically removed. The ball valve and the bottom valve of the gun head are opened for fast filling. When the weight reaches the small material value, the filling speed decreases. When the weight reaches the target amount and the advance amount is reduced, the two valves are full Closed, the filling head automatically lifts the gun to the outside of the barrel, the drip-proof plate is connected to the liquid, and the error is detected and displayed... until the filling is finished;

4.The operator presses the [Barrel Out] button, and the heavy barrel is sent to the end of the conveyor. A filling process is completed.

|

Maximum weighing

|

1500kg

|

|

Minimum weighing

|

100kg

|

|

Precise

|

±0.5%

|

|

Explosion-proof grade

|

ExdiaIIbT4

|

|

Filling speed

|

200L(20-30 barrel/H) IBC 8-12 barrel

|

|

Structural materials

|

SUS304/316 stainless steel

|

|

Weighing table size

|

1400*1400*1000mm

|

|

Conveyor roller size

|

1400*1400*338mm

|

Jintan Sunshine Machinery Co., LTD was founded in 2001, which has more than 15 years experience in machinery manufacturing. It is located in West zone, No.33 building, FENGHUANGCHENG Industrial Park, Jintan District, Changzhou City, Jiangsu Province,China.We devote ourselves to the development, research and production of pesticide, chemical,food,daily chemical packaging machinery. Our main products including: full automatic and semi automatic bottle unscrambler, filling, capping, and labeling machine, we also provide solution of whole production line for customer.All our products are sold well in more than 20 provinces and cities in china, we also exported to about thirty countries and areas with strong technical force, advanced equipment, scientific management system and perfect after-sales service.

Welcome to visit Sunshine Machinery, thank you!

Package Type :

As usual, we adopt wooden case as package type. It’s suitable for long-distance transport.According to customers’ special demand, we could adopt sheet iron case and so on.

Delivery Type:

By sea or air,decide by customers.

1. Installation, debug

After equipment reached the workshop of customer, place the equipment according to plane layout we offered. We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and the salary.

2. Training

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, thetechnician of buyer could master the operation and maintenance, could adjustthe process and treat different failures.

3. Quality guarantee

We promise that our goods are all new and not used. They're made of suitable material, adopt new design. The quality, specification and function all meet the demand of contract.

4. After sales

After checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician.

After quality guarantee, we offer technology support and after sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems.

Q1: Do you have reference project?

A1: We have reference project in most countries,If we get the permission of the customer who has brought the machines from us ,we can tell you their contact imformation,you can go to vist their factory.And you are always welcome to come to visit our company,and see the machine running in our factory,we can pick you up from the station near our city.Contact our sales people you can get video of our reference running machine

Q2: Do you provide customized service

A2: We can design the machines according your requirements(materil ,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

Q3: What's your guarantee or the warranty of the quality if we buy your machines?

A3: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Hot Searches