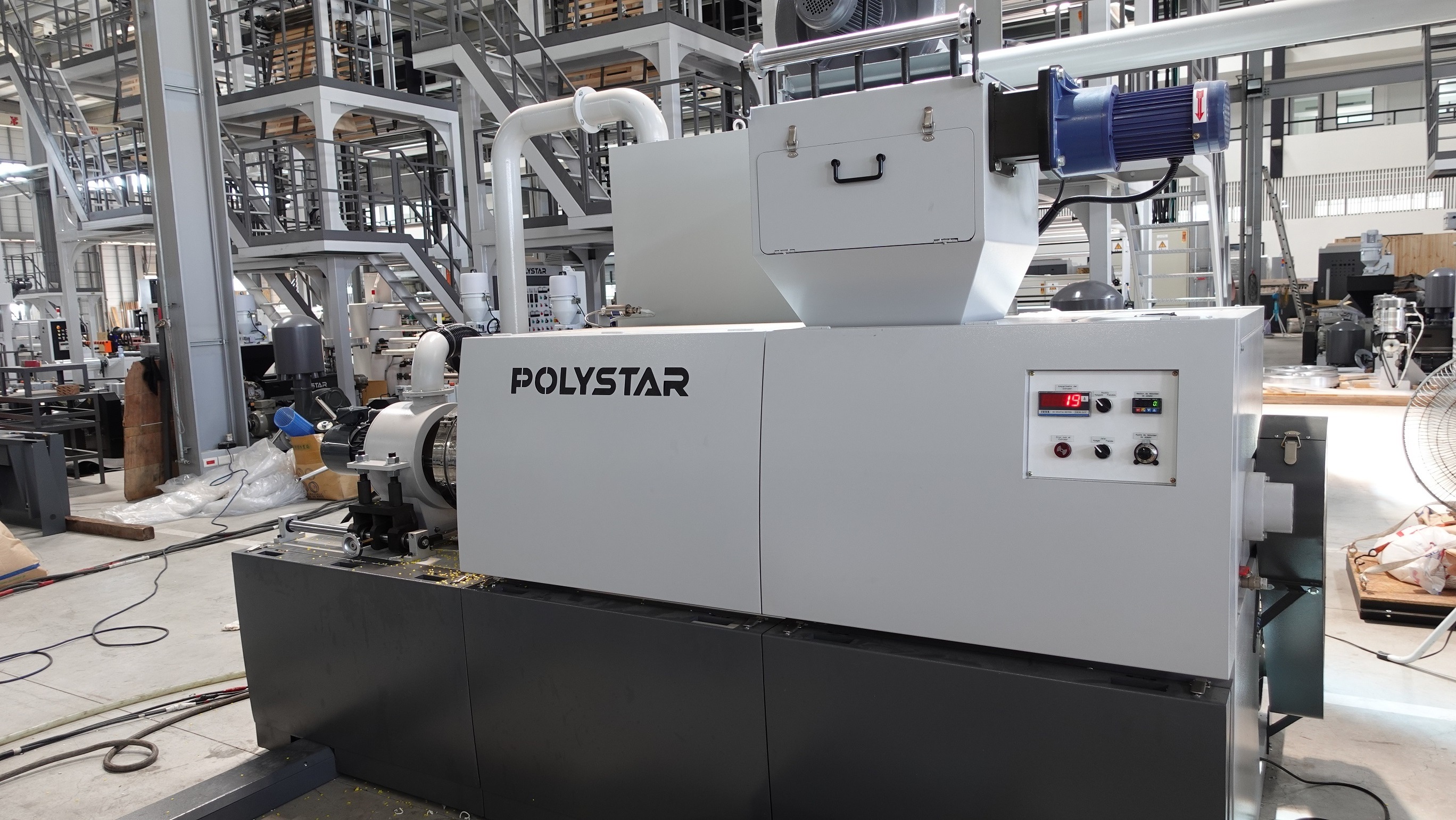

This air-cooled

plastic pelletizing machine

does not require any water consumption and takes up very little space, it can fit right next to or in between blown film machines. The pellets produced by the hot die face pelletizer are 100% dry and can be put directly back into the production line for immediate reprocessing.

This equipment is highly recommended for packaging film producers of different types of film and bags, such as flat bags, T-shirt bags, garbage bags, food packaging film, shrink film and many others.