wood sawdust briquette: Put it in the steel basket, then use the hoist to put the steel basket into the inner stove;

woo log, wood branch, bamboo etc: Put them neatly in the basket, then put the basket into the inner stove;

coconut shell, nuts shell etc: Beat into even part, then fix the small part in the basket and put the gasket into the inner stove.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2800*1800*2500

-

Voltage:

-

220V/380V

-

Power:

-

0.75-2.2kw

-

Weight (KG):

-

500

-

Item:

-

carbonization furnace

-

Product name:

-

charcoal production machine

-

Energy Consumption:

-

20-25kg firewood

-

color:

-

as per client request

-

raw material:

-

coconut shell,wood charcoal,bamboo,wood

-

Exhaust gas:

-

Recycling

-

Function::

-

Carbonization

-

Temperature:

-

400-600 degree

-

installation:

-

Engineer's Guidance

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Ainuok

-

Effective Volume:

-

10.88

-

Dimension(L*W*H):

-

2800*1800*2500

-

Voltage:

-

220V/380V

-

Power:

-

0.75-2.2kw

-

Weight (KG):

-

500

-

Item:

-

carbonization furnace

-

Product name:

-

charcoal production machine

-

Energy Consumption:

-

20-25kg firewood

-

color:

-

as per client request

-

raw material:

-

coconut shell,wood charcoal,bamboo,wood

-

Exhaust gas:

-

Recycling

-

Function::

-

Carbonization

-

Temperature:

-

400-600 degree

-

installation:

-

Engineer's Guidance

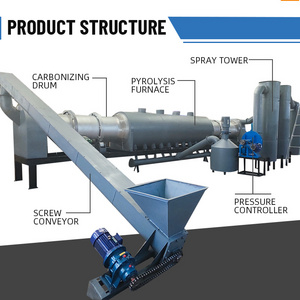

Biochar making machine/hardwood carbonization furnace/charcoal production machine

Biochar making machine/hardwood carbonization furnace/charcoal production machine is a kind of way to make all kinds of biomass into charcoal. And carbonization furnace is kind of equipment to make this happen.

Application :

Biochar making machine/hardwood carbonization furnace/charcoal production machine uses advanced hot gas flow carbonization technology, greatly improve the carbonization rate, and less land occupation, simple and convenient operation, safety and environmental protection, high production efficiency, can save a lot of energy. Airflow hoisting carbonization furnace adopts the hoisting combination structure, use the method of hoisting cooling, one day can be carbonized multiple furnaces, greatly shorten the production cycle, improve the charcoal production efficiency, which is the ideal equipment for large and medium-sized scale charcoal producers to produce charcoal.This type carbonization furnace is the best seller and exported to many countries for charcoal briquettes plant.

Biochar making machine/hardwood carbonization furnace/charcoal production machine can carbonize raw materials like biomass briquettes, wood. coconut shell. etc. continuously and so save carbonization time, and the hoisting system saves labor force, the whole carbonizing process is smoke-free.

Biochar making machine/hardwood carbonization furnace/charcoal production machine includes 1 outer stove. 3 inner stoves. 3 covers. one hoist frame and a purification system. This new design not only can improve the efficiency. but also can reduce the labor force. With the development of the society. green development gradually become ou goals and objectives. people realize the importance of environmental protection. More and more people choose carbonization stove to produce the charcoal.

Working Process

Working principle

How to produce charcoal? It divides into 4 processes:

1. Put the material in the stove

2. Carbonization

Seal the stove then carbonization work begins.

Carbonize time

Wood briquette: about 6 hours;

Other material: depend on the moisture and the material size;

3. Take out gasket

Take the gasket by the hoist, put it somewhere to self-cool down. Then put another fixed gasket into the inner stove for another carbonization process.

Get the charcoal

After the cool down process finished, you get the charcoal, take it out from the gasket!

Note:

Things to pay attention to on making high-quality charcoal in carbonization process

1.If your material is high in moisture, take 3-5 hours to evaporate the moisture of wood logs (small fire 90 -150 degree, white and heavy color water vapor smoke).

2.A six hours step on carbonization is like the following: 150-280 degree (yellow and heavy smoke), 3 hours, 280-450 degree (thin and smaller smoke), 2 hours, 450-higher, 1 hour (lucid and blue color smoke).

3.Long cooling time helps to make better quality charcoal.

Advantages of Biochar making machine/hardwood carbonization furnace/charcoal production machine :

1.Not only it has best carbonization effect and shortest carbonization time,

2.It can collect wood tar oil and exhaust gas.

3.After processed, this gas can used recycling fuel.

4.Also it is no any open fire, totally dry distillation

5.The carbonization temperature can be controlled and adjusted,highest temperature can reach 800-1000 °C

The Raw material

Almost all the biomass can be made into charcoal, we list some as follow: Wood logs, wood branches, sawdust briquettes, biomass waste, coconut shell, Macadamia nut, cashew nut shell, bamboo, etc

Where do we use Charcoal?

♦

Charcoal in industry: It is mainly used in combining carbon of industrial materials,

metallurgy, and the carburizing carbon of chemical industry.

♦ Charcoal in agriculture and animal husbandry: It can raise the soil temperature,

maintain soil moisture, mitigate the organic fertilizers and improve soil PH.

♦ Charcoal in life: People often use charcoal heating, barbecue,

as well as the fuel used to the tea and tobacco drying.

|

Model

|

Power

|

Capacity

|

Inner volume

|

Weight

|

Temperature

|

Machine include

|

|

QHL-1

|

0.75kw

|

3t/24h

|

2.75*3

|

4 Ton

|

400-600 degree

|

1outer stove, 3inner pots with 3 caps,

one 3-ton lifting device, 1 purification tank |

|

QHL-2

|

0.75kw

|

6t/24h

|

2.75*6

|

8 Ton

|

400-600 degree

|

2 outer stove, 6 inner pots with 6 caps,

one 5-ton hoisting equipment with e-motor, 1 purification tank

|

|

QHL-3

|

0.75kw

|

9t/24h

|

2.75*9

|

12 Ton

|

400-600 degree

|

3 outer stove, 9 inner pots with 9caps, one 5-ton hoisting equipment with e-motor, 1purification tank

|

|

QHL-4

|

0.75kw

|

12t/24h

|

2.75*12

|

16 Ton

|

400-600 degree

|

4 outer stove, 12 inner pots with 12caps, one 5-ton hoisting equipment with e-motor, 4purification tank

|

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

In addition, load it by shipping container directly.

One 20'GP can load 3sets.

Delivery Details

: within 20 work days after the payment

Anyang Ainuok After 10 years development, now our company becomes an independent economic entity with the integration of science, engineering and trading department. our products and are widely accepted in both domestic and now open the world market, service to more than 100 countries.

Q: Are you trading company or manufacturer ? A: We are factory.

Q:What materials do you use to dry ? A:You can use almost all the biomass materials.

Q: What is the max moisture of your material ? A:Our machine can dry biomass materials between 60% and 70%.

Q: What is the temperature? A:230℃

Q: What is the carbonization rate ? A:can reach 99%.

Q: Installation time A:5-7days

Q: What is carbonization time ? A:Usually, 6-9hours.

Q: When the charcoal is finished ? A:There is no smoke and smoke is blue lucid, the process is finished.

Q: How many times should we cool the charcoal ? A:It takes 8-10hours.

Q: Could you offer complete briquette machine production line ?

A:Yes, we will allocate suitable production line, according to your special requirement, such as crusher, conveyor, dryer, briquette machine, etc.

Q: Can we use the machine directly ?

A:Yes, start the machine, when temperature reach 320 degree, put your materials into hopper, you will get fuel briquette

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have other questions, pls feel free to contact us as below: