Main Features:

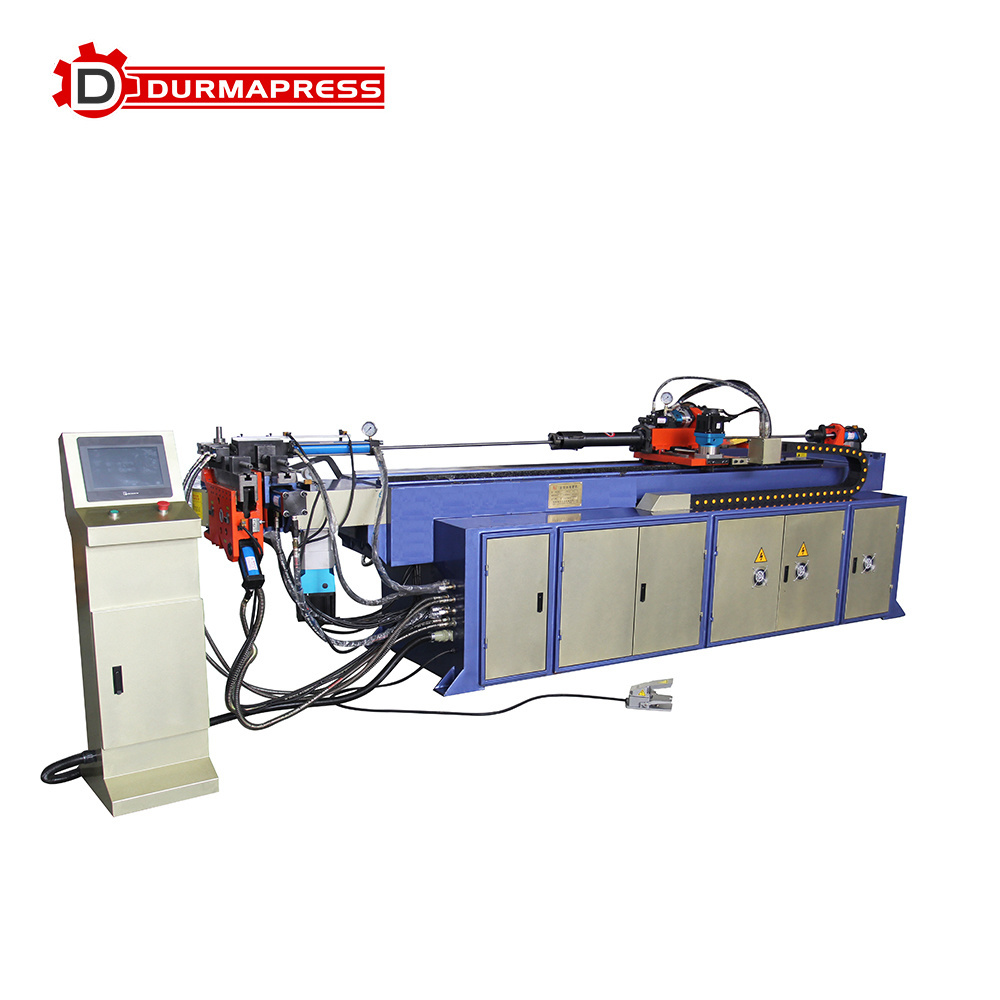

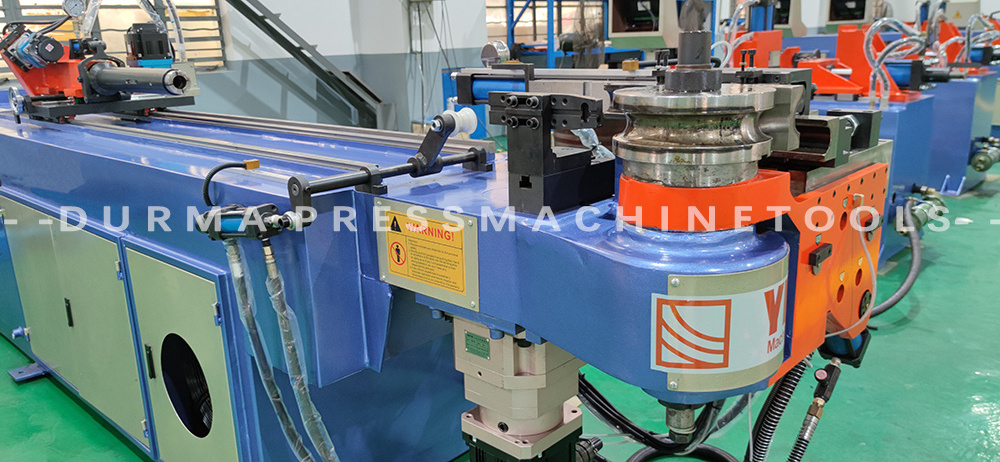

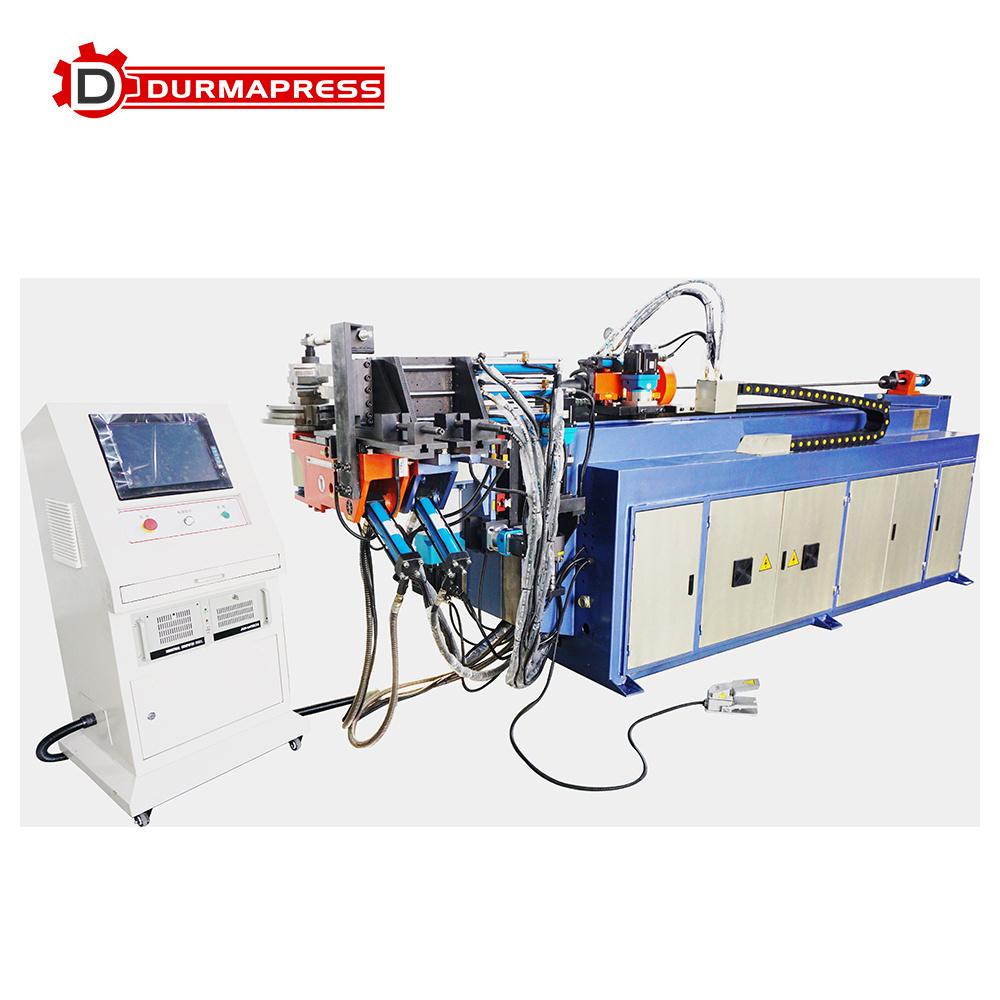

* Structural style: * NC Pipe bending machine adopts boom lifting clamp structure

* Hydraulic bending mode

* Hydraulic guide side pushin mechanism

* Hydraulic system is equipped with water cooling device , which is convenient for users to control the oil temperature

* Pipe bending direction is clockwise from top view

* Electrical control and operation interface

* The operation interface of NC hydraulic pipe bending machine adopts single chip microcomputer

* Digital display resolution : turn 0.15°

* NC hydraulic pipe bending machine adopts single chip microcomputer controller

* Bending parameters can be set ( preset ) on the operation interface .

* NC Hydraulic pipe bending machine with the following characteristics .

* Maximum memory capacity can up to 16 bends per group

* Directly input bending machining paramenets , the machine can be executed step by step and suspended during automatic operation

so that the specal pipe can be manually interfered when bending , and the automatic operation can be resumed with automatic and

manual pause , emergency stop function

* Working program and bending program memry storage time is unlimited and will not be lost due to power outage or long-term use .

* Program edit with minor correction input , the original processing data will not be lost due to multi-times program modification .

* With processing quantity and processing time counting function

* Real time display the position and bending angle of each action axison screen

* In case of any accident or error during auomatic processing , the machine can be suspended , and the machine can continue to finish the unfinished work , so as to advoid the waste .

* Automatic or manual mode setting can be set according to the difference of processing feature, such as whether there is a piercing heart , auxiliary push and so on .

* With multiple delay parameter settings , the most appropriate time difference can be set for each acttion axis to meet the requirements of various bending changes .

* The machine is with automatic detection function of each buttom and circuit output / input board , which can easily find the possible fault location .

* Closed loop control