- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hotel

-

Design Style:

-

Industrial

-

Type:

-

DKJL

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DKJL

-

Model Number:

-

DK-800

-

Name:

-

calcium silicate board

-

Density:

-

230-240 kg/m3

-

Liner shrinkage:

-

≤2%

-

Thermal Conductivity:

-

0.113-0.125w/m.k

-

Thickness:

-

25/50/65mm

-

Service temp.:

-

650C

-

compression strength:

-

15.5MPa

-

Flexural Strength:

-

6.5MPa

-

asbestos content:

-

non

-

Size:

-

Customized

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

graphic design

-

Application:

-

Hotel

-

Design Style:

-

Industrial

-

Type:

-

DKJL

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DKJL

-

Model Number:

-

DK-800

-

Name:

-

calcium silicate board

-

Density:

-

230-240 kg/m3

-

Liner shrinkage:

-

≤2%

-

Thermal Conductivity:

-

0.113-0.125w/m.k

-

Thickness:

-

25/50/65mm

-

Service temp.:

-

650C

-

compression strength:

-

15.5MPa

-

Flexural Strength:

-

6.5MPa

-

asbestos content:

-

non

-

Size:

-

Customized

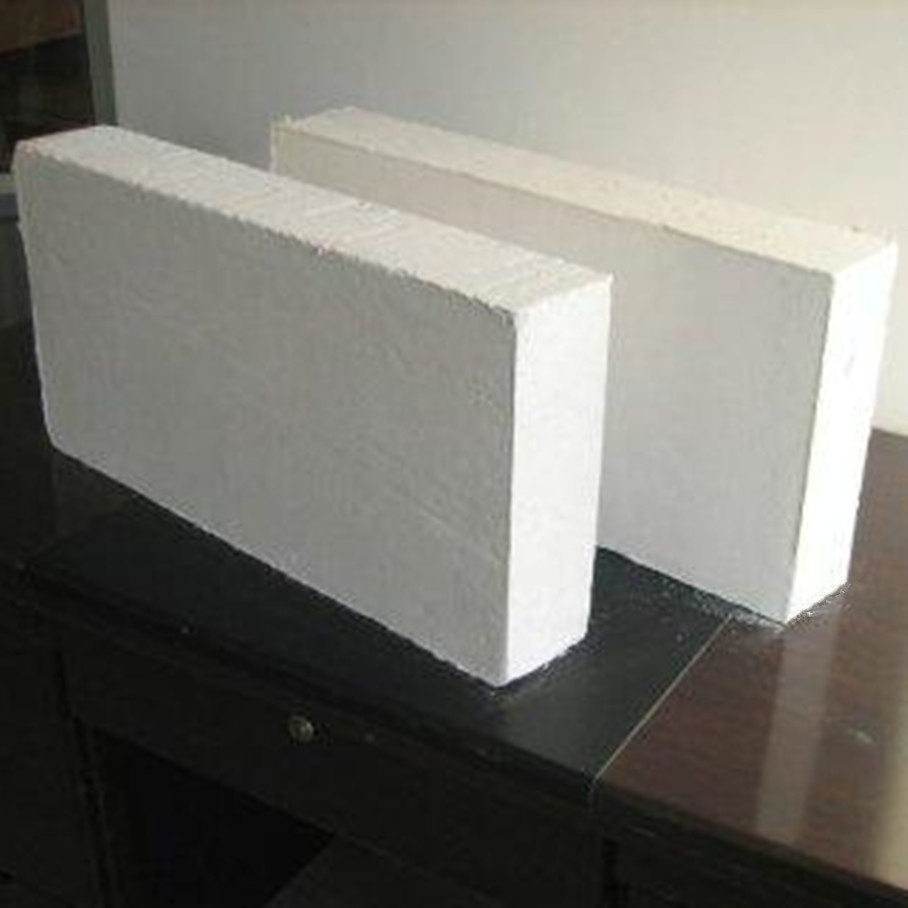

Factory Price High Strength Insulation Calcium Silicate Boards

Calcium silicate board is developed for nonferrous metal industry with density range 230-240kgs/m3, used for conveying, casting and molding of molten alumina and other non-ferrous metals, also can be used as clamping fixture in glass industry. Besides its own thermal insulation, its non-stick aluminum characteristics have been greatly played. High strength, good machinability, can be used to machine precision products and complex parts by Numerical Control Machine Tools.

There are two types of board reinforced by glass fiber and carbon fiber.

Features and advantage

1. Low thermal conductivity and less heat lost in high temperature

2. Not wetted by molten alumina

3. Resistance to thermal shock

4. Excellent machining performance

5. Asbestos-free

Application

1. Ladle insulating panels

2. Clamping fixture for car glass

3. Dip tubes

4. Pouring spouts

5. Hot-top rings

6. Stopper pins

7. Rolling edge

8. Floats

9. Launders

calcium silicate board technical index

|

Item |

DK-800 |

DK-801 |

|

Type |

Glass fiber reinforced |

carbon fiber reinforced |

|

bulk density kg/m3 |

230-240 kg/m3 |

230-240 kg/m3 |

|

temp limit °C |

650 °C |

650 °C |

|

continuous service temp °C |

less 650 °C |

less 650 °C |

|

flexural strength MPa |

6.5 |

8 |

|

compressive strength(break)5%deformation |

15.5 MPa 12MPa |

17 MPa 13 MPa |

|

coefficient of thermal expansion/°C |

7*10-6 |

7*10-6 |

|

thermal conductivity (W/M.K) |

100 °C 200 °C 300 °C 400 °C 0.113 0.120 0.121 0.125 |

100 °C 200 °C 300 °C 400 °C 0.103 0.114 0.124 0.133 |

|

thermal shrinkage% after 24 hours lineal % Thickness % |

650 °C 700 °C 750 °C 850 °C 1000 °C 0.15 0.25 0.28 0.35 0.49 0.86 1.00 1.10 1.30 3.50 |

650 °C 700 °C 750 °C 850 °C 1000 °C 0.10 0.18 0.20 0.21 0.36 0.60 0.80 0.90 1.10 2.40 |

pictures of calcium silicate board

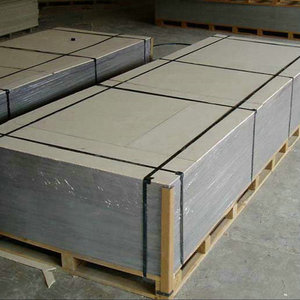

Package of calcium silicate board : inner plastic bags,outer cartons and pallet with heat shrinkable film.

We also received OEM service, the package can be designed according to your requirements.

Shipping of calcium silicate board : By vessel or by train from any Chinese port, Samples can be delivered by International express.

Package pictures of calcium silicate board

1. Timely response,

Timely response to your inquiry, multiple choice recommendations based on your demand, quickly respond mails and provide solutions.

2. Sample evaluatioon

calcium silicon board Sample and trial order are accepted for the quality evaluation.

3. Strict quality control

Arrange production on time and control quality strictly.

4. Shorter delivery time.

Book the earliest vessel or plane to guarantee the delivery time.

5. Professional Services

Provide all the detailed news and pictures from order to delivery;

Offer relative export documents and original certificate if needed;

Warm and considerable after-sale service