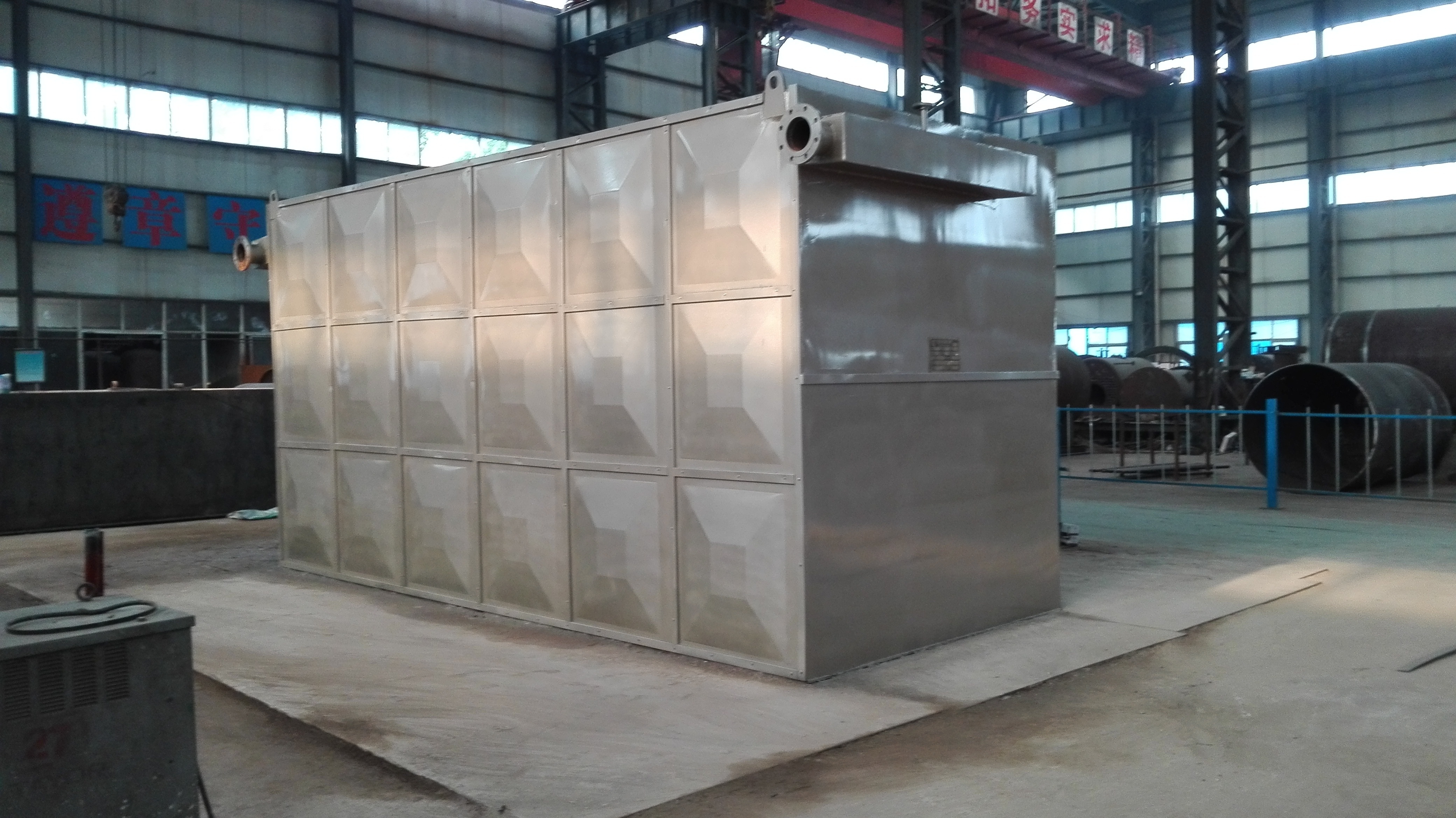

YLW biomass heat transfer oil boiler is a chain

type horizontal heat transfer oil boiler. This type of boiler uses biomass pellets as fuel and heat transfer oil as the medium.

The hot oil circulating oil pump is used to force the medium to circulate in the liquid phase, and the heat energy is transmitted

to the The working principle of returning to the heating furnace for reheating after using the thermal equipment, and obtaining a

stable high temperature under low pressure to work.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yongxing

-

Dimension(L*W*H):

-

customization

-

Weight:

-

customization

-

Product name:

-

Biomass Fired Thermal Oil Heater Coal Fired Thermal Oil Boiler

-

Boiler type:

-

Coal biomass wood fired thermal oil heater boiler

-

Advantages:

-

Precise temperature, small heat loss

-

Application field:

-

Chemical/ textile/food industry

-

Quality:

-

100% Tested

-

After sales service:

-

Online service

-

Operation style:

-

Automatic

-

Certification:

-

ISO CE

-

Thermal efficiency:

-

80-86&

-

Design fuel:

-

coal,biomass, wood,solid

Quick Details

-

Core Components:

-

Boiler

-

Steam Production:

-

other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yongxing

-

Dimension(L*W*H):

-

customization

-

Weight:

-

customization

-

Product name:

-

Biomass Fired Thermal Oil Heater Coal Fired Thermal Oil Boiler

-

Boiler type:

-

Coal biomass wood fired thermal oil heater boiler

-

Advantages:

-

Precise temperature, small heat loss

-

Application field:

-

Chemical/ textile/food industry

-

Quality:

-

100% Tested

-

After sales service:

-

Online service

-

Operation style:

-

Automatic

-

Certification:

-

ISO CE

-

Thermal efficiency:

-

80-86&

-

Design fuel:

-

coal,biomass, wood,solid

Products Description

YLW biomass heat transfer oil boiler

Product Paramenters

|

Item

|

Unit

|

Boiler model

|

|

|

|

|

|

||||||

|

|

|

YLW-700

|

YLW-1400

|

YLW-2400

|

YLW-2900

|

YLW-4200

|

YLW-7000

|

||||||

|

Rated capacity

|

KW

|

700

|

1400

|

2400

|

2900

|

4200

|

7000

|

||||||

|

Rated pressure

|

Mpa

|

0.8

|

|

|

|

|

|

||||||

|

Output temperature

|

℃

|

280/320

|

|

|

|

|

|

||||||

|

Input temperature

|

℃

|

250/290

|

|

|

|

|

|

||||||

|

Circulating flow

|

m3/h

|

45.7

|

87.4

|

149.8

|

155

|

225

|

383.467

|

||||||

|

Heat carrier volume

|

m3

|

0.46

|

1.19

|

2.08

|

2.73

|

4.36

|

7.06

|

||||||

|

Thermal effiency

|

%

|

80

|

80

|

81

|

82

|

83

|

83

|

||||||

|

Applicable fuel

|

coal and biomass

|

|

|

|

|

|

|

||||||

|

Fuel consumption

|

kg/h

|

187

|

373

|

621.3

|

756

|

1189

|

2052

|

||||||

|

Exhaust temp.

|

℃

|

224.8

|

201

|

166.02

|

167.8

|

142.96

|

137.12

|

||||||

|

Size

|

mm

|

4800×2100×2900

|

6050×2530×3460

|

6300×3100×3750

|

6970×2730×3760

|

8800×3410×5110

|

10100×3300×2860

|

||||||

|

Weight

|

Ton

|

16.9

|

22

|

28.6

|

24.2

|

30

|

18.2

|

||||||

Details Images

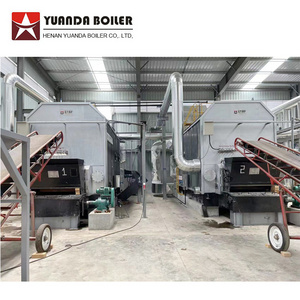

Performance Characteristics -- Coal Biomass Wood Fired Thermal Oil Heater Boiler

● There are technical measures to strictly control the content of air, moisture and other low volatiles in the working medium before the boiler circulates heat

● Compact structure greatly saves the floor area of the boiler room

● The steel furnace body and chain grate can be combined on site, which not only reduces transportation costs, but also shortens the installation period

● Reasonable furnace arch design prolongs the stay time of the flue gas in the furnace, making the combustion more complete

● Higher operating temperatures can be obtained at lower operating pressures

● Thermal efficiency can be maintained at an optimal level under various loads

● Use sawdust, agricultural and forestry waste, etc. as fuel to turn waste into treasure

● The furnace is composed of double close-packed coils, which reduces the heat load on the surface of the tubes and improves safety

● There is a heating surface arranged in the smoke chamber, which avoids the short circuit of the flue gas caused by the high-temperature flue gas directly washing the partition wall and causing the partition wall to fall off.

● The medium flow is reasonable, flowing from low to high, making it difficult for the gas generated during operation to stay in the furnace, and can be easily discharged from the system

Hot Searches