Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

+_2mm

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BIG BOSS

-

Dimension(L*W*H):

-

2700x2300x2200mm

-

Weight:

-

2500 KG

-

Function:

-

oil filling and packing machine

-

Bottle type:

-

PET Plastic Bottle

-

Usage:

-

Liquid Packaging

-

Material:

-

SUS304/316

-

Capacity:

-

800-4000bph

-

Control:

-

PLC+ Touch Screen

-

Processing:

-

Filling+weighing+capping

-

Feature:

-

Automachine

-

Filling head:

-

4 - 24 Heads

-

Packing type:

-

Cartons+ Wooden Packaging

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Oil

-

Filling Accuracy:

-

+_2mm

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BIG BOSS

-

Dimension(L*W*H):

-

2700x2300x2200mm

-

Weight:

-

2500 KG

-

Function:

-

oil filling and packing machine

-

Bottle type:

-

PET Plastic Bottle

-

Usage:

-

Liquid Packaging

-

Material:

-

SUS304/316

-

Capacity:

-

800-4000bph

-

Control:

-

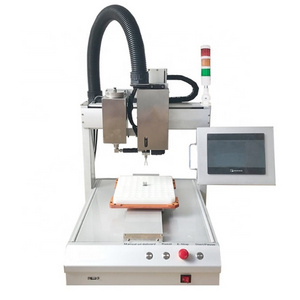

PLC+ Touch Screen

-

Processing:

-

Filling+weighing+capping

-

Feature:

-

Automachine

-

Filling head:

-

4 - 24 Heads

-

Packing type:

-

Cartons+ Wooden Packaging

Product Description

oil filling machine

Product Features

1) This machine has compact structure, flawless control system, and is convenient To operate with high grade automatism

2) All the parts contacting the media are made of high quality stainless steel, Able to bear corrosion and easily rinsed

3) Adopts high precision and high speed ration filling valve so that the oil level is exact with loss, ensuring high quality filling

4) The capping head has constant twisting movement, which ensures capping Quality, without damaging caps

5) Adopts high efficiency cap tidying system, with flawless equipment for feeding caps and protecting

6) Needs only to change the pinwheel, bottle entering screw and arched board when changing bottle models, with simple and convenient operation

7) There is flawless equipment for overload protecting, which can protect effectively machine and operator safety

Product Paramenters

|

Model

|

OK-XGF6/1

|

OK-XGF8/3

|

OK-XGF12/4

|

OK-GF18/6

|

OK-GF24/6

|

|

Filling heads

|

6

|

8

|

12

|

18

|

24

|

|

Capping heads

|

1

|

3

|

4

|

6

|

6

|

|

Capacity

|

600-800

|

1000-1200

|

1800-2000

|

2500-3000

|

4000-6000

|

|

Weight

|

1200Kg

|

2000Kg

|

2500Kg

|

3200Kg

|

4200Kg

|

|

Motor power

|

3.7KW

|

5.5KW

|

7.5KW

|

11KW

|

15KW

|

Products Description

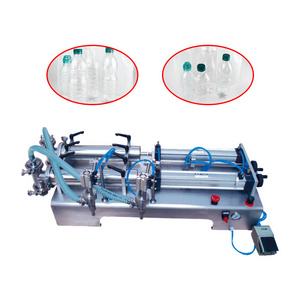

This type machine is suitable for filling viscous,inviscid and corrosive liquid.It's widely applied in plant oil,chemical liquid,and daily chemical industry.It adopts linear type filling,electromechanical&instrucmental intergration controlling.It's simple and rapid for changing the varieties with unique design and superior capability.It's appearance accords with the international machinery concept.

Oil Filiing Part

The system adopts weighing type filling with

high measuring accuracy and is not affected

by materials.

The filling head adopts a

vacuum

suction and anti-drip device, and

the filled

material

has no bubbles, and the effect

is

good.

Using

world renowned brands of

electrical and

pneumatic components, the

failure

rate is

low,

the performance is stable and reliable,

and the service life is long.

Oil Capping Part

The capping machine is an important part of the production line.

The capping machine is one-time capping to ensure the tightness of the capping and the flatness of the cap after capping.

The capping machine positions the heavy barrel directly below the capping plate, and then performs capping work after positioning, stepping on the capping foot switch to perform capping.

Recommend Products

1. All Stainless Steel

1. Filling machine air conveyor SUS304

2. Washing part SUS304

3. Filling tank and nozzle SUS316

4. Capping heads SUS304

5. Machine frame SUS304

6. Filling machine flat conveyor SUS304

2. NSK Gear (Janpan)

Nsk Gear use in ok filling machine

model list

1. NSK Gear Model 6006

2. NSK Gear Model 6203

3. NSK Gear Model 6805

4. NSK Gear Model 6002 6204 ......

3. Festo (Germany)

OK machine control System

Touch screen SIEMENS

PLC SIEMENS

Inverter SIEMENS

Air action control Festo Germany

AC contactor SIEMENS

Bottle blowing machine

It adopts double driving structure which is a new and advanced driving device for the thermal shrink sleeve machine, that is, four-wheel driving, self-centering and balanced pressure of four wheels.

In the packaging machinery industry, the film wrapping machine is the abbreviation of the wrapping film packaging machine, sometimes called the winding machine and the wrapping machine.

-

Energy saving. High efficient. Adapt to customer factory layout

- Special lubrication system, keep products clean, health, safety .

- Electric eyes design keep whole line running safety and quickly .

- Overload protection mechanism to effectively ensure the safety of the machine.

Product Packaging

Hot Searches