- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WELL

-

Voltage:

-

Customized

-

Weight:

-

20000 KG

-

Name:

-

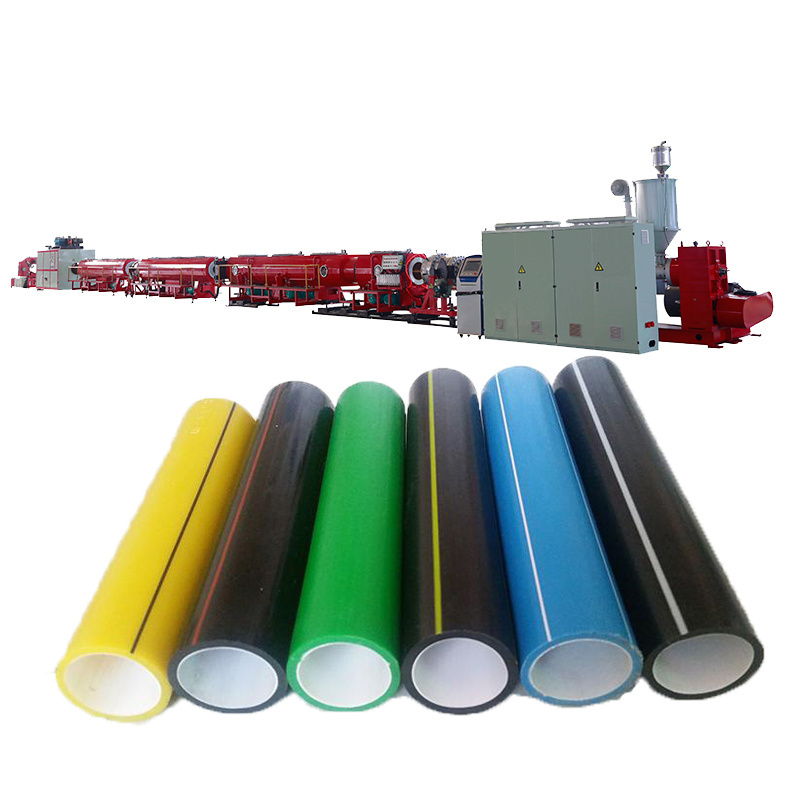

PE pipe production line

-

Raw material:

-

PE

-

Capacity:

-

1200kg/h

-

Motor:

-

Siemens China

-

Contactor:

-

Siemens China

-

Inverter:

-

ABB

-

Main motor power:

-

90kw

-

Application Field:

-

Underground gas and water supply lines

-

After-sales Service Provided:

-

Field Installation and Training

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw diameter (mm):

-

150

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WELL

-

Voltage:

-

Customized

-

Weight:

-

20000 KG

-

Name:

-

PE pipe production line

-

Raw material:

-

PE

-

Capacity:

-

1200kg/h

-

Motor:

-

Siemens China

-

Contactor:

-

Siemens China

-

Inverter:

-

ABB

-

Main motor power:

-

90kw

-

Application Field:

-

Underground gas and water supply lines

-

After-sales Service Provided:

-

Field Installation and Training

Product Description

PE PIPE EXTRUSION LINE

Application:

1)Town tap water supply pipe

2)Coal gas, dry gas, natural gas transporting pipe

3)Town blow-off pipe

4)Industrial and agricultural liquid transporting pipe

5)Electric water transporting pipe

6)Sea water transporting pipe

7)Multi-layer reinforced functional pipe

Technology and advantages

1.

Special screw barrel feeding greatly improves the extrusion capacity

2.

Unique screw design to achieve better plasticizing effect and good product quality

3.

Precise temperature control system ensures plasticizing performance of materials

4.

Exquisite high torque gear box, running more smoothly

5.

Automatic water temperature and water level control and special independent filter are used in empty tank and spray tank

6.

Provides a stable 2-12 - claw tractor device

7.

Energy saving, excellent performance, easy to maintain

|

NO

|

Name

|

Quantity

|

|

1

|

Automatic Feeder and Drier

|

1set

|

|

2

|

SJ-65×33 Single Screw Extruder

|

1set

|

|

3

|

SJ-25×25 Color Line Co-Extruder

|

1set

|

|

4

|

Mould Body

|

1set

|

|

5

|

Vacuum Calibration & Cooling tank

|

1set

|

|

6

|

Cooling tank

|

1set

|

|

7

|

Haul-off unit

|

1set

|

|

8

|

Cutting machine

|

1set

|

|

9

|

Double-Position Winder

|

1set

|

Specification

|

Model

|

Pipe Range

(mm)

|

Extruder Model

|

Main motor

(kw)

|

Max Capacity

(kg/h)

|

|

WRD-63

|

Φ20-63

|

WRD60/38

|

90

|

450

|

|

WRD-110

|

Φ20-110

|

WRD60/38

|

110

|

500

|

|

WRD-160

|

Φ40-160

|

WRD60/38

|

110

|

500

|

|

WRD-250

|

Φ50-250

|

WRD75/38

|

160

|

680

|

|

WRD-450

|

Φ160-450

|

WRD90/38

|

250

|

1000

|

|

WRD-630

|

Φ280-630

|

WRD90/38

|

280

|

1100

|

|

WRD-800

|

Φ315-800

|

WRD120/38

|

315

|

1300

|

|

WRD-1200

|

Φ500-1200

|

WRD120/38

|

355

|

1400

|

|

WRD-1600

|

Φ1000-1600

|

WRD90/38&WRD90/38

|

250+250

|

2000

|

|

WRD-2000

|

Φ1000-2000

|

WRD90/38&WRD90/38

|

280+280

|

2200

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches