- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50hz

-

Power:

-

20kw

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

5000*2000*2000mm

-

Year:

-

2023

-

Beverage:

-

fruit juice, concentrate juice, tea beverage, coffee

-

Bottle type:

-

PET plastic bottle

-

Filling temperature:

-

85℃ hot filling

-

Filling way:

-

gravity filling

-

Final package:

-

3 in 1 washing filling and capping

-

Blending system:

-

syrup filter, mixing tank, double filter..

-

Pasteurization:

-

6m length

-

Bottle labeling:

-

shrink sleeve labeling machine

-

Finished bottle packaging:

-

PE film wrapping machine

-

Name:

-

pineapple fruit juice beverage manufacturing making plant machine

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Baiji

-

Type:

-

New

-

Voltage:

-

380V 50hz

-

Power:

-

20kw

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

5000*2000*2000mm

-

Year:

-

2023

-

Beverage:

-

fruit juice, concentrate juice, tea beverage, coffee

-

Bottle type:

-

PET plastic bottle

-

Filling temperature:

-

85℃ hot filling

-

Filling way:

-

gravity filling

-

Final package:

-

3 in 1 washing filling and capping

-

Blending system:

-

syrup filter, mixing tank, double filter..

-

Pasteurization:

-

6m length

-

Bottle labeling:

-

shrink sleeve labeling machine

-

Finished bottle packaging:

-

PE film wrapping machine

-

Name:

-

pineapple fruit juice beverage manufacturing making plant machine

Product Description

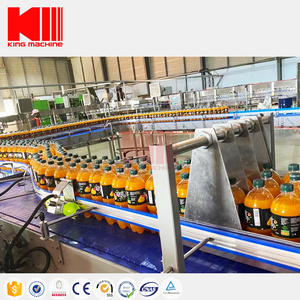

Fully automatic orange mango pineapple fruit juice beverage manufacturing making bottling filling plant machine

Juice Filling Machine is mainly designed for filling hot temperature liquid.

For example juice, tea drinks etc which are made of concentrate juice.

The final filling temperature will be around 85-90 degree centigrade.

Once the thermal meter in juice filling machine is lower than the temperature, juice will be return to sterilizing machine again through return system.

Detailed Images

Juice blending system

Sugar melting tank → syrup filter → blending tank → double filter → storage tank → homogenizer → storage tank → vacuum degasser → storage tank → plate type sterilization

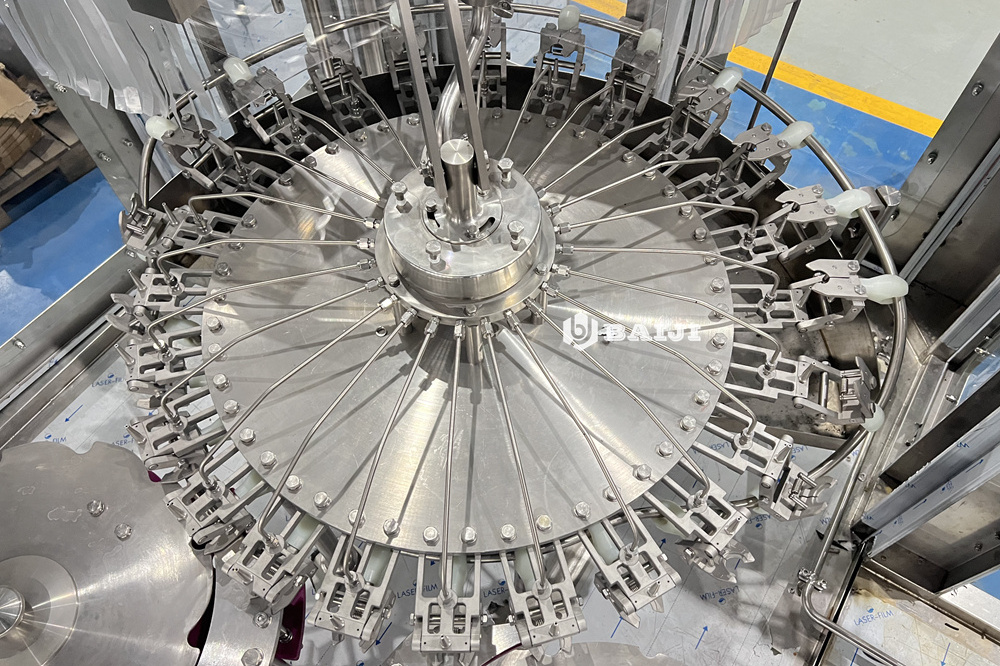

Automatic Juice Bottle Washing Filling Capping 3 in 1 Machine

( Monoblock Type )

It can work for different size bottle from 200ml to 2000ml, but do make sure the same cap. Actually, we can provide different models filling unit according to your speed needs. Min. 2000-3000bph, Max. 24000bph.

|

Technical parameter

|

|

|

|

|

|

|||||

|

Model

|

RCGF8-8-3

|

RCGF14-12-5

|

RCGF18-18-6

|

RCGF24-24-8

|

RCGF32-32-8

|

|||||

|

Capacity(for 500ml)

|

2000

|

3000-4000

|

4000-6000

|

8000-10000

|

10000-12000

|

|||||

|

Suitable bottle shapes

|

PET circular or square

|

|

|

|

|

|||||

|

Bottle diameter(mm)

|

Dia50-Dia115mm

|

|

|

|

|

|||||

|

Bottle height (mm)

|

160-320mm

|

|

|

|

|

|||||

|

Compressor air

|

0.3-0.7Mpa

|

|

|

|

|

|||||

|

Filling type

|

hot filling

|

|

|

|

|

|||||

|

Rinsing pressure

|

>0.06Mpa <0.2Mpa

|

|

|

|

|

|||||

|

Application

|

fruit juice

|

|

|

|

|

|||||

Pasteurization tunnel

It is usually used after fruit juice beverage finished hot filling and sealing, when enter the spray tunnel, the water with the function of high-pressure pump, uniformly spray on the bottle body. The bottles move slowly in the chain, when they are out the tunnel, they can reach the normal temperature, then achieve the purpose of cooling. This machine can also be used for secondary sterilization for fruit juice.

Automatic shrink sleeve labeling machine

It consists of auto labeling machine, heat shrink tunnel and steam generator.

It adopts international advanced technology, cover the circle label on the pet bottle. And then hot shrinking to fix on the position which bottle body designated.

Automatic PE film wrapping machine

To pack several bottles into one package, make it easier for delivery.

You can have different group style, 24 bottles one package, 12 bottles one package, etc. It is changeable.

Related Products

Our company

Zhangjiagang Baiji Machinery Co., Ltd.

is a professional manufacturer of beverage machinery in China. Our main products have: water filling production line, juice filling production line, carbonated drink filling production line, beer, cooking oil, wine, sauce filling production line, and all other auxiliary equipment. The liquid can be PET bottled, glass bottled, aluminum canned, 5 gallon barreled and so on.

We are not only a manufacturer of mechanical equipment, but also can provide you with plant design, equipment layout, waterway, circuit and airway layout, etc. Our task is to ensure the smooth production of your factories and help you win your markets.

Certifications

Hot Searches