- Product Details

- {{item.text}}

Quick Details

-

Power:

-

27-100kw

-

Dimension(L*W*H):

-

40 m x 30m x 6m

-

Weight:

-

50 kg

-

Product name:

-

20-80tph Mobile Hot Mix Drum Asphalt Plant

-

Capacity:

-

20-80t/h

-

Type:

-

Continuous drum mixing asphalt plant

-

Drying drum:

-

Counter current

-

Asphalt elevator:

-

Scraper type

-

Pneumatic system:

-

AIRTAC,TAIWAN, CHINA

-

Control system:

-

SIEMENS,GERMAN

-

Operation:

-

Manual

-

Color:

-

Client's Customized

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZOOMLINE

-

Voltage:

-

220V/380V-50Hz

-

Power:

-

27-100kw

-

Dimension(L*W*H):

-

40 m x 30m x 6m

-

Weight:

-

50 kg

-

Product name:

-

20-80tph Mobile Hot Mix Drum Asphalt Plant

-

Capacity:

-

20-80t/h

-

Type:

-

Continuous drum mixing asphalt plant

-

Drying drum:

-

Counter current

-

Asphalt elevator:

-

Scraper type

-

Pneumatic system:

-

AIRTAC,TAIWAN, CHINA

-

Control system:

-

SIEMENS,GERMAN

-

Operation:

-

Manual

-

Color:

-

Client's Customized

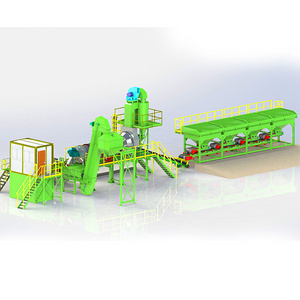

Drum Bitumen Mixing Plant 20-80tph Mobile Hot Mix Drum Asphalt Plant

20-40t/h Mobile Hot Mix Drum Asphalt Plant

40-60t/h Mobile Hot Mix Drum Asphalt Plant

60-80t/h Mobile Hot Mix Drum Asphalt Plant

ZAP-C(M) series 20-80t/h continuous asphalt mixing plant is very different with batch asphalt mixing plant. It produce the asphalt mixture in the drum which also dry the aggregate continuously.

• The structure is simple and modular design, easily transport and installation

• The investment of plant is lower than batch mixing plant

• Counter current drying drum design, drying efficiency is high, save energy

• Scraper type elevator delivery asphalt mixture cleaning and smoothly

• Multi-fuel burner

• Fully automatic controls

Compositions of ZAP-C(M) series continuous asphalt mixing plant:

Cold aggregate supply system Drying drum

Bitumen tank Electrical control system

Technical parameters of ZAP-C(M) series asphalt drum mix plant

| Items | ZAP-C(M)20 | ZAP-C(M)40 | ZAP-C(M)60 | ZAP-C(M)80 |

| Plant Capacity | 20t/h | 40t/h | 60t/h | 80t/h |

| Cold Aggregate Feeding System | ||||

| Hopper capacity | 3x4m3 | 4x4m3 | 4 x 6.5m3 | 4 x 6.5m3 |

| Belt capacity | 40t/h | 60t/h | 80t/h | 100t/h |

| Drying System | ||||

| Drying drum size | 1000x4500mm | 1200x5000mm | 1500x6500mm | 1500x6500mm |

| Drying capacity | 15-25t/h | 40-50t/h | 60-70t/h | 80-100t/h |

| Burner (oil) | 40-130kg/h | 70-300kg/h | 100-400kg/h | 60-600kg/h |

| Fuel consumption (oil) | 6.5-7kg/t | 6.5-7kg/t | 6.5-7kg/t | 6.5-7kg/t |

| Dust Collecting System | ||||

| Exhaust Fan power | 5.5kw | 7.5kw | 30kw | 30kw |

| Finished Asphalt Silo | 2m3 | 2.5m3 | 4.5m3 | 4.5m3 |

| Asphalt Temperature | 130-160 ℃ | 130-160 ℃ | 130-160 ℃ | 130-160 ℃ |

| Total Power | -27kw | -57kw | -92kw | -100kw |

Henan ZOOMLINE Machinery CO., Ltd is a professional supplier of asphalt mixing plant and support equipments that draws on years' experiences and technology developments.

Our main asphalt mixing plants include:

Stationary asphalt mixing plant(ZAP-S series)

Mobile asphalt mixing plant(ZAP-M series)

Continuous asphalt mixing plant(ZAP-C series)

ZOOMLINE is based in Nanyang Longsheng Industrial Park of Henan. To be a professional asphalt mixing plant, recycling asphalt plant, bitumen equipment supplier, we have one R & D manufacturing center which cover an area about 50,000 square meters.

Our asphalt mixing plants have got CE,ISO,EAC certificate. Nowadays, our asphalt plant products have been sold to Russia, Cambodia, Bangladesh, Egypt, Uzbekistan, Kyrgyzstan, Pakistan, Georgia, Indonesia, Belgium and Thailand etc.

Welcome to our factory to visit asphalt mixing plants!

Our professional after-sales services team could provide timely and reliable service for any of our customers who need support.

Technical support

1.Professional technical team, to provide users with equipment selection, layout program design, construction programs and other consultation services.

2.Technical guidance during equipment operation, PLC with remote monitoring, large capacity recipe storage,special needs customization.

3.Equipment installation, commissioning, training technical support. Provide a full range of technical training on operation, maintenance for users and equipment manager, to provide multiple technical advice.

4.The equipment upgrades, relocation technical support in the future. To provide seamless equipment technology upgrades,perfect and efficient removal plan.

OEM Scheme

1. Provide OEM service to other manufactures.

2. Seek for productive manufacture OEM in our company sales area.

3. Flexible cooperation type.