- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

AIM Magnet

-

Model Number:

-

N35-N52

-

Magnet Name:

-

Waterproof Hidden sew Neodymium Magnets for clothing for handbag

-

sample:

-

samples are free if have storage

-

Density:

-

7.45g/mm3

-

Accurate tolerance:

-

±0.05mm ~ ±0.1mm

-

Working Temperature:

-

80℃~230℃

-

Coating:

-

Plastic/Rubber/Epoxy,etc

-

Qualified rate:

-

≥98%

-

Testing:

-

SST: 24~72 hours

-

Delivery:

-

By DHL (3~5days)

-

Certificate:

-

RoHS, Reach, ISO9001:2008

Quick Details

-

Tolerance:

-

±1%

-

Grade:

-

neodymium magnet

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

AIM Magnet

-

Model Number:

-

N35-N52

-

Magnet Name:

-

Waterproof Hidden sew Neodymium Magnets for clothing for handbag

-

sample:

-

samples are free if have storage

-

Density:

-

7.45g/mm3

-

Accurate tolerance:

-

±0.05mm ~ ±0.1mm

-

Working Temperature:

-

80℃~230℃

-

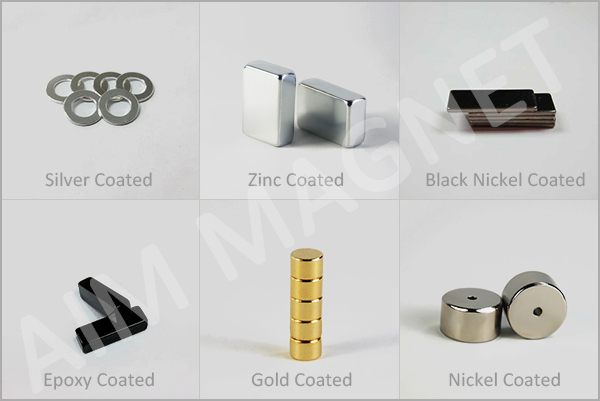

Coating:

-

Plastic/Rubber/Epoxy,etc

-

Qualified rate:

-

≥98%

-

Testing:

-

SST: 24~72 hours

-

Delivery:

-

By DHL (3~5days)

-

Certificate:

-

RoHS, Reach, ISO9001:2008

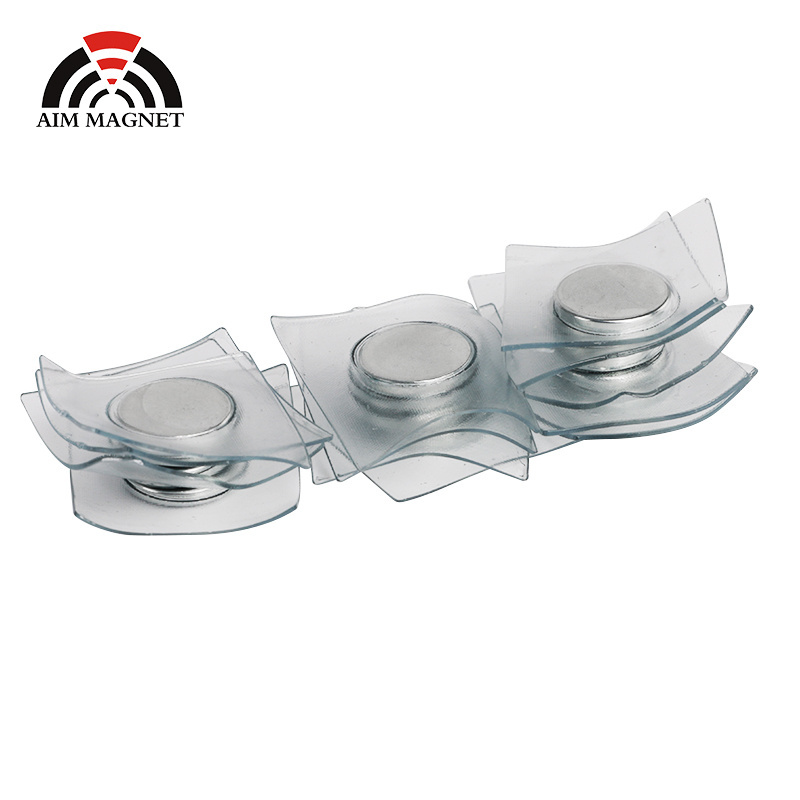

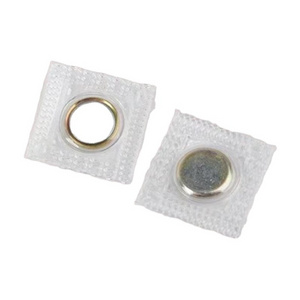

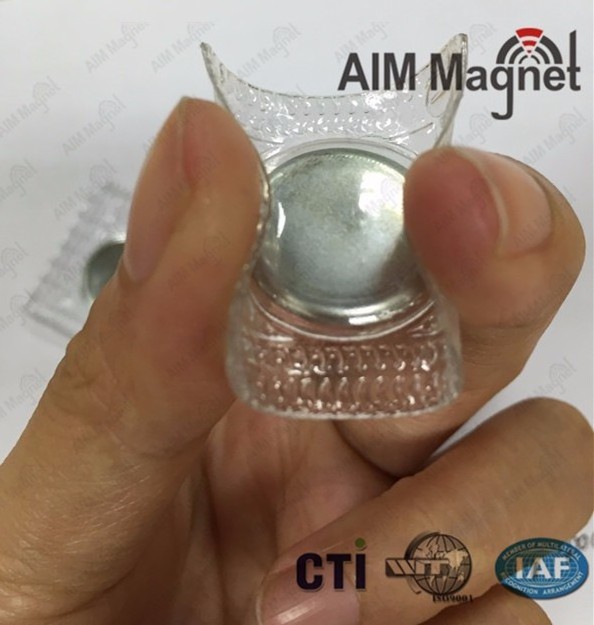

Waterproof Hidden sew Neodymium Magnets for clothing for handbag fasteners clasps buttons

1. Factory Price

2. Fast delivery (5~7 days)

3. Most strongest Customized Magnet

4. OEM Accept

5. AIM Magnet Company Found in 2006

Waterproof Hidden sew Neodymium Magnets for clothing for handbag fasteners clasps buttons

| Material |

Sintered Neodymium-Iron-Boron ( NdFeB ) |

|

|

Size |

Various kinds or according to customers' request |

|

|

Shape |

Customized (block,disc,Cylinder, Bar, Ring,Countersunk, Segment, hook, cup, Trapezoid, Irregular shapes ,etc) |

|

|

Performance |

Customised (N33 N35 N38 N40 N42 N45 N48 N50 N52 …...) |

|

|

Coating |

Customised (Zn, Ni-Cu-Ni, Ni, Gold, Silver, Copper, Epoxy, Chrome, etc) |

|

|

Size tolerance |

±0.05mm for diamater /thickness, ±0.1mm for width/ length |

|

|

Magnetization |

Thickness Magnetized, Axially Magnetized, Diametrally Magnetized, Multi-poles magnetized, Radial Magnetized. |

|

|

Max. Working Temperature |

Grade |

Max. Operating Temperatures |

|

N35-N52 |

80°C (176°F) |

|

|

33M- 48M |

100°C (212°F) |

|

|

33H-48H |

120°C (248°F) |

|

|

30SH-45SH |

150°C (302°F) |

|

|

30UH-40UH |

180°C (356°F) |

|

|

28EH-38EH |

200°C (392°F) |

|

|

28AH-35AH |

220°C (428°F) |

|

|

Applications |

Neodymium(NdFeB) Magnet are widely used in many fields, such as motors, sensors, microphones, wind turbines, wind generators, printer, switchboard, packing box , loudspeakers, magnetic separation, magnetic hooks, magnetic holder, magnetic chuck, ect. |

|

|

Notice |

1.

Be careful fragile and clip hand.

4. Not allowed Children play with naked neodymium magnet. |

|

The coating advantages of AIM Magnet Co.,Ltd,

1. Our own electroplating factory ensures quality and delivery!

2. Thickness of coating is 4-6μm thicker than counterparts, coating adhesion is better, and corrosion resistance is stronger.

| Surface | Coating | Thickness (Microns) | Color | Resistance |

| Passivation | 0-1 | Silver Grey | Temporary Protection | |

| Nickel | Ni+Ni | 10-20 | Bright Silver | Excellent against Humidity |

| Ni+Cu+Ni | ||||

| Zinc | Zn | 8-20 | Bright Blue | Good Against Salt Spray |

| C-Zn | Shinny Color | Excellent Against Salt Spray | ||

| Tin | Ni+Cu+Sn | 15-20 | Silver | Superior Against Humidity |

| Gold | Ni+Cu+Au | 10-20 | Gold | Superior Against Humidity |

| Copper | Ni+Cu | 10-20 | Gold | Temporary Protection |

| Epoxy | Epoxy | 15-25 | Black, Red, Grey | Excellent Against Humidity & Salt Spray |

| Ni+Cu+Epoxy | ||||

| Zn+Epoxy |

1.Why are chosen us?

- We are a professional magnet manufacturer since 2006. Our plating factory is the benchmark in the Shenzhen

NdFeB industry.

- No returned goods for five years in Europe market.

- We provide magnets for a dozen of Fortune Global 500 enterprises such as Apple, Samsung, Lenovo etc.

- In Europe market, 80% permanent magnets used for range hood are from AIM Magnet Co., Ltd.

- Our company is the main supplier of American top wine box.

- With rich exporting experiences with neodymium magnets, we build supply chain to offer neodymium magnets

with professional service.

2. How to control the magnetic property?

- Hight stander raw material

3. How to control the tolerance?

- 1. before ginding and cuting, we inspection the black product tolerance.

- 2. before and after coating, we will inspection the tolerance by AQL standard

- 3. before delivery, will inspection the tolerance by AQL standard

4. How to guarantee the consistancy?

- 1. the sintering control will make sure the perfect consistancy.

- 2. we cut magnet by multi-wire sawing machine to guarantee the dimension consistancy.

5. How to control coating ?

- 1. we have a coatIng factory

- 2. after coating, first inspection by visual, and second is salt spray test, nickel 48-72 hours, zinc 24-48 hours

6. How to control the packing?

- 1. standard packing,

- 2. the cartons must can be bear a man's weight.

- 3. the cartons must be well after fall down test from 1m high position. and the inner packing must not change position