- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

WINDBELL

-

Model Number:

-

WB-SS160PLUS and WB-SP300

-

Power:

-

AC220V, 0.2A, 50/60HZ

-

Working temperature:

-

-20 to 60 ℃

-

Display:

-

800*600, 8'' full color LCD

-

Replay output:

-

2 groups

-

Monitor tanks:

-

Up to 12

-

Ports:

-

2 RS232, 1RS485, 1USB

-

Leak sensor:

-

Yes, 28 max

-

Ex-proof grade:

-

[Ex ia Ga] IIA

-

Size:

-

Console:32*27*42cm Probe:243*12*12cm

-

Product name:

-

Float Ball Automatic Tank Gauge Liquid Level Meter For Fuel Station

Quick Details

-

Grade:

-

Industrial

-

Warranty:

-

1 year

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WINDBELL

-

Model Number:

-

WB-SS160PLUS and WB-SP300

-

Power:

-

AC220V, 0.2A, 50/60HZ

-

Working temperature:

-

-20 to 60 ℃

-

Display:

-

800*600, 8'' full color LCD

-

Replay output:

-

2 groups

-

Monitor tanks:

-

Up to 12

-

Ports:

-

2 RS232, 1RS485, 1USB

-

Leak sensor:

-

Yes, 28 max

-

Ex-proof grade:

-

[Ex ia Ga] IIA

-

Size:

-

Console:32*27*42cm Probe:243*12*12cm

-

Product name:

-

Float Ball Automatic Tank Gauge Liquid Level Meter For Fuel Station

Windbell fuel station automatic tank gauge system mainly includes of SP series magnetostrictive probe and SS series console . Help managers to know the fuel level, water level and temperature in the underground fuel storage tank of the fuel station anytime, anywhere.

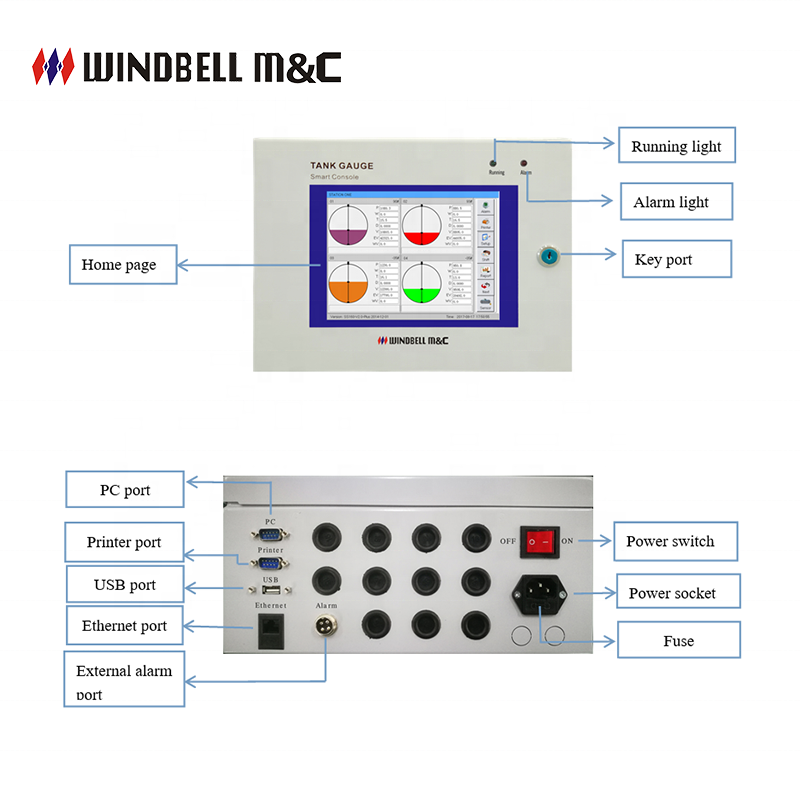

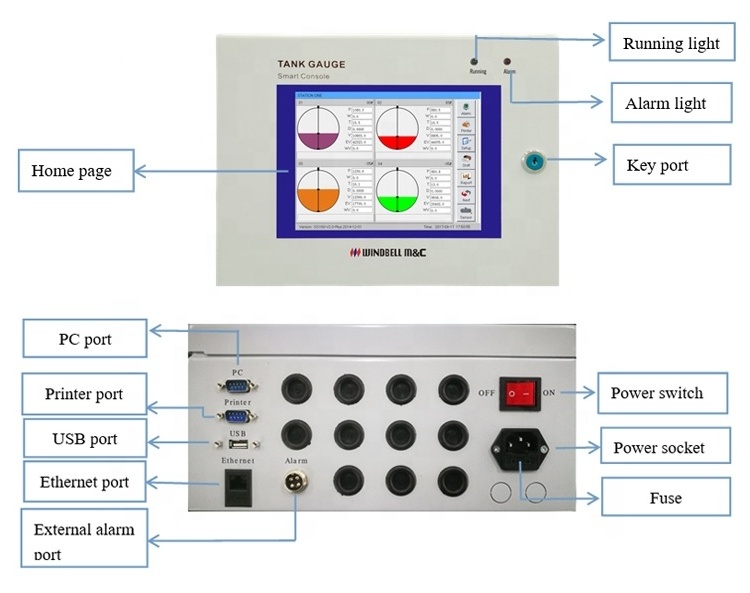

The smart console is the display terminal of the automatic tank gauge system and can detect 1 to 12 tanks at the same time. It can monitor product level, water level, temperature, product volume, water volume, empty volume , all kinds of alarms, inventory and delivery information in real time.

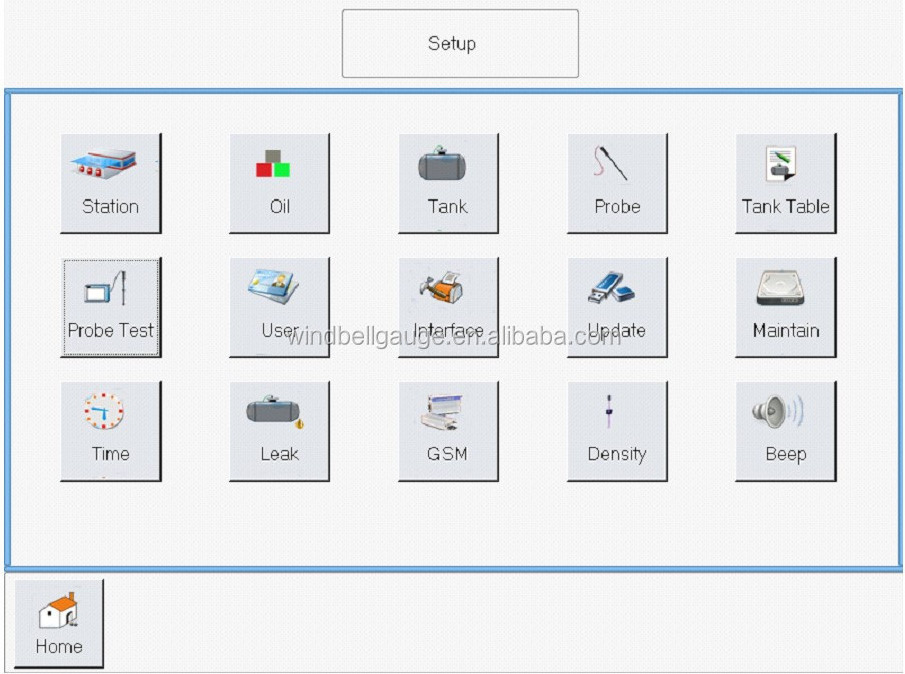

Smart console (please see below) is a powerful operation platform, the data processing and record center, can communicate with probe by RS485, and also offer safety and reliable power to probe. Together with SP300 series magnetostrictive probe constitutes the complete automatic tank gauge system.

It consists of TFT colorful touch screen, core processing CPU, safety barriers and power module. Display and operating screen are 8’’ size, 800*600 resolutions. The CPU which composed of the advanced embedded processor and peripheral circuit is the control center of the whole tank gauge system. The safety barrier is intrinsic safe parts, offer safety power to probe. International graphic touch screen and user-friendly icon, makes it is easy for new user.

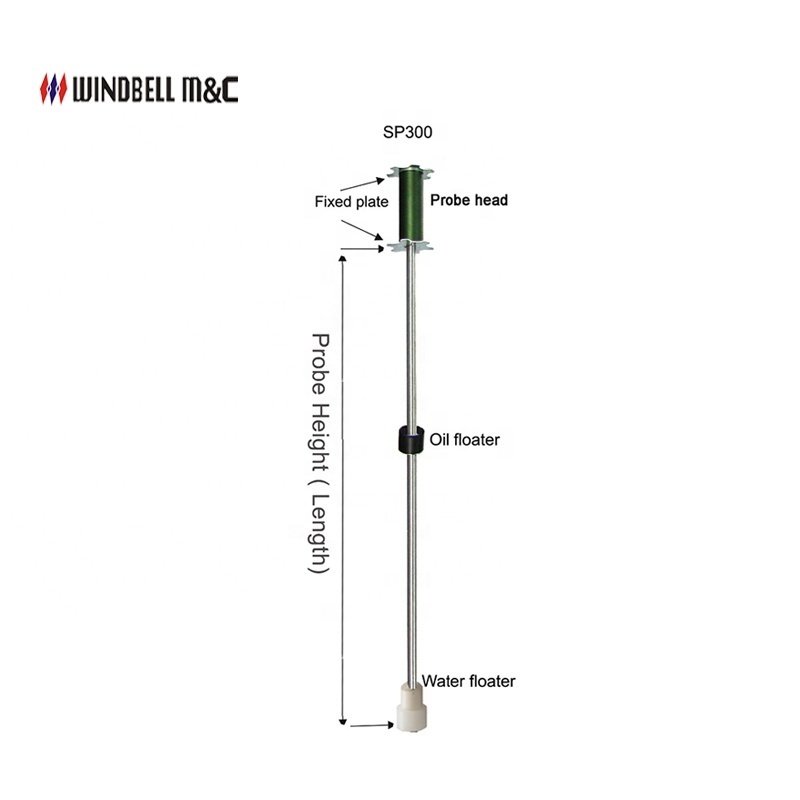

APP is available for FREE.

SP300 Magnetostrictive probe is mainly composed of probe head, temperature sensors, protection steel pipe, magnetostrictive waveguide wire and floaters with magnet inside. Insert probe into underground tank, floaters float on the liquid surface, and slides up and down on rod according to the changes of liquid level. Processing measured data of product level, water level, density values (option), and average temperature of five-points, then transmit these data to smart console by di gital communication port.

Smart Console SS160Plus

- International graphic touch screen and user-friendly icons, easy to use.

- Standard measurement unit, mm or inch, liter or gallon, meet different requirements from different countries.

- Display product volume and water volume, empty volume, product level and water level, and product temperature for individual tanks.

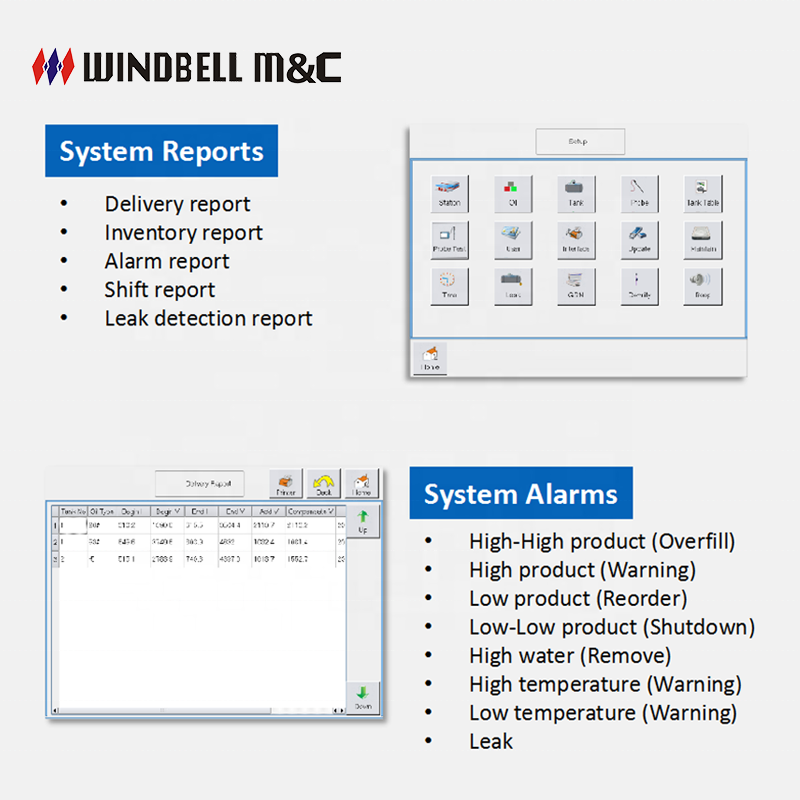

- Reports include current inventory, delivery history, alarm, shift, leak, system log, SMS.

- Operating language optional, support English, Spanish, Portuguese, French, Russian. And can be customized.

- Support import & export data, tank volume table import, very convenient for console configuration.

- Monitor up to 12 probes (tanks). Standard configuration is 6 probes.

- Monitor up to 40 leak sensors.

- Printing reports by optional external printer or optional built-in printer without any software.

- Automatic alarm function can show any abnormal status of tanks.

- Administrator password, different authorization, safe management.

- Compatible with PC remote software on site's computer.

- Support standard static or dynamic leak detection on 0.38 L/H or 0.76 L/H.

- Optional density probe can monitor product quality. Fuel density can be shown in real time on the console.

- Open communication protocol, can connect to the central control system of mainstream fuel dispensers, totally satisfy management demand of oil retail companies.

- Update program by USB port, one-touch operation, easy and convenient.

- iTank APP, support Android and IOS system, monitor tank information remotely in real time.

- Boot welcome interface can be customized.

Magnetostrictive Probe SP300

- ±0.5mm accuracy.

- RS485 communication protocol.

- 3-in-1 measurement, detect fuel height, fuel temperature and water height at the same time.

- 4 wires cable.

- IP68 protection grade.

- Intrinsically safe grade.

- ATEX, EAC, CQST, SIL approved.

- Length customized production.

- Applied in Gasoline, Kerosene, Diesel, Ethanol gasoline, Methanol gasoline, Approved light oil.

| Smart Console SS160Plus | |

| Power | AC220V ±10%, 50/60Hz |

| Working temperature | -20 to 60ºC (-4 to 140ºF) |

| Display | 8-inch LCD touch screen, 800x600 resolution |

| Ex-proof grade | [EX ia Ga] IIA |

| Monitor probes | Standard is 6,Up to 12, |

| Leak sensor | Support, 40 Max |

| Relay output | 2 groups. Node capacity AC250V/3A. DC30V/3A |

| SMS module | Optional |

| GPRS module | Optional |

| Running/Alarm indicator | Yes |

| WIFI function | No |

| Inventory and delivery management | Yes |

| Density and mass measurement | Yes |

| Output voltage | DC 12V |

| Safety barrier | WB-GSB03 |

| Built-in printer | Optional |

| External printer | Support |

| RS485 port | 1 |

| RS232 port | 2 |

| USB port | 1 |

| Ethernet port | 1 |

| Buzzer alarm | Yes |

| External sound-light alarm | Support, optional |

| Tank table | Yes, simulate/input/upload |

| Reports | Inventory, delivery, shift, alarm, leak detection test, system log, SMS for optional |

| PC remote software | PCR200 |

| Anti-theft function | Yes |

| Dimension (L*W*H) | 30×23×14.5 cm, 8kg |

| Magnetostrictive Probe SP300 | |

| Power supply | DC12V |

| Precision | ±0.5mm |

| Repeatability | ±0.1mm |

| Resolution of product level | 0.0069mm |

| Resolution of temperature | 0.0078ºC |

| Resolution of water level | 0.0069mm |

| Temperature range | -40 to 85ºC(-40 to 185ºF) |

| Points of temperature measured | 5 |

| Maximum communication distance | 1200m |

| Communication | RS485 |

| Intrinsic safety parameter |

Power port: Ui = 15V DC, Ii= 400mA, Pi = 1.5W, Ci =

3.63

μF, Li = 0mH;

Signal port: Ui = 7.14V DC, Ii= 147mA, Pi = 260mW, Ci = 32.6 μF, Li = 0mH; |

| Associated apparatus | WB-GSB03 safety barrier |

| Explosion proof grade | Ex ia IIA T4 Ga, Ex II 1G Ex ia IIA T4 Ga |

| Protection grade | IP6 8 |

| Applicable medium | Gasoline, kerosene, diesel, Ethanol gasoline, Methanol gasoline, Approved light oil |

| Definition of wires | Blue - Power + : Brown - RS485A : White - RS485B : Black - Power - |

| Communication address | 6 digits, see the"Manufacturing code"or S/N code on probe nameplate, this is also Probe ID in commun i cation with console and FMS |

| Dimension (L*W*H) | 243*12*12cm,5kg |

How the magnetostrictive probe working in the Automatic Tank gauge system?

How to select suitable probe for the tanks?