- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

1400x180x1520mm

-

Model:

-

JZ-500L-4

-

Material width:

-

300-500mm

-

Maximum diameter of mother roll:

-

600mm

-

Rewinding length:

-

2-50 m/roll

-

Material thickness:

-

0.008-0.05mm

-

Rewinding speed:

-

0-200m/min (adjustable)

-

Inner diameter of unwinding paper tube:

-

3 inches (76mm)

-

Inner diameter of rewinding paper tube:

-

Can be customized (2 sets provided for free)

-

Size:

-

1400x180x1520mm

Quick Details

-

Power:

-

2kw, 2kw

-

Place of Origin:

-

China

-

Brand Name:

-

MILES

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

1400x180x1520mm

-

Model:

-

JZ-500L-4

-

Material width:

-

300-500mm

-

Maximum diameter of mother roll:

-

600mm

-

Rewinding length:

-

2-50 m/roll

-

Material thickness:

-

0.008-0.05mm

-

Rewinding speed:

-

0-200m/min (adjustable)

-

Inner diameter of unwinding paper tube:

-

3 inches (76mm)

-

Inner diameter of rewinding paper tube:

-

Can be customized (2 sets provided for free)

-

Size:

-

1400x180x1520mm

Product Description

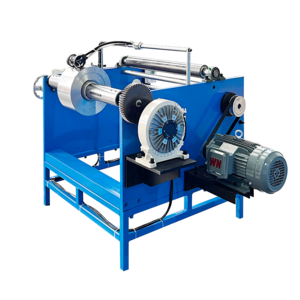

Fully Automatic Aluminium Foil Roll Rewinder Machine Aluminum Stretch Cling Film Foil Roll Rewinding Machine

This unit includes automatic paper feeding tube, automatic cutting, and automatic roll changing, which effectively improves production efficiency and saves labor costs. It is an ideal equipment for household aluminum foil rewinding.

Specification

|

Model

|

JZ-500L-4

|

|

|

Material width

|

300-500mm

|

|

|

Maximum diameter of mother roll

|

600mm

|

|

|

Rewinding length

|

2-50 m/roll

|

|

|

Material thickness

|

0.008-0.05mm

|

|

|

Rewinding speed

|

0-180m/min (adjustable)

|

|

|

Inner diameter of unwinding paper tube

|

3 inches (76mm)

|

|

|

Inner diameter of rewinding paper tube

|

Can be customized (2 sets provided for free)

|

|

|

Power

|

2KW

|

|

|

Size

|

1400x180x1520mm

|

|

|

Wight

|

1.2T

|

|

|

hot melt glue

|

yes

|

|

|

PLC

|

Omron

|

|

|

touchscreen

|

Delta (Taiwan)

|

|

|

Frequency converter

|

Delta (Taiwan)

|

|

|

contactor

|

Schneider

|

|

|

relay

|

Schneider

|

|

|

switch

|

Chint

|

|

|

sensor

|

AirTAC

|

|

|

switching power supply

|

Omron

|

|

|

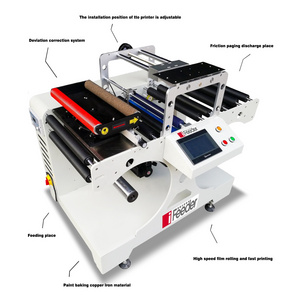

The equipment has the functions of fully automatic paper tube loading, automatic gluing, automatic cutting, automatic tube unloading and transportation.

|

|

|

Feature:

1- Using variable frequency control, adjustable speed 0-180m/min.

2- Fast winding and changing speed, high production efficiency.

3- Fully automatic PLC control, all procedures are completed on the touch screen.

4- This machine has low noise, fast speed and long life.

5- If the customer needs to change the size of the paper tube, he only needs to change the size of the chuck. Compared with traditional tinfoil rewinding machines, this machine occupies a small area, has high roll changing efficiency, is simple to operate, and has advanced systems, which greatly improves production efficiency.

Details Images

Recommend Products

Packing & Delivery

wooden case.

Hot Searches