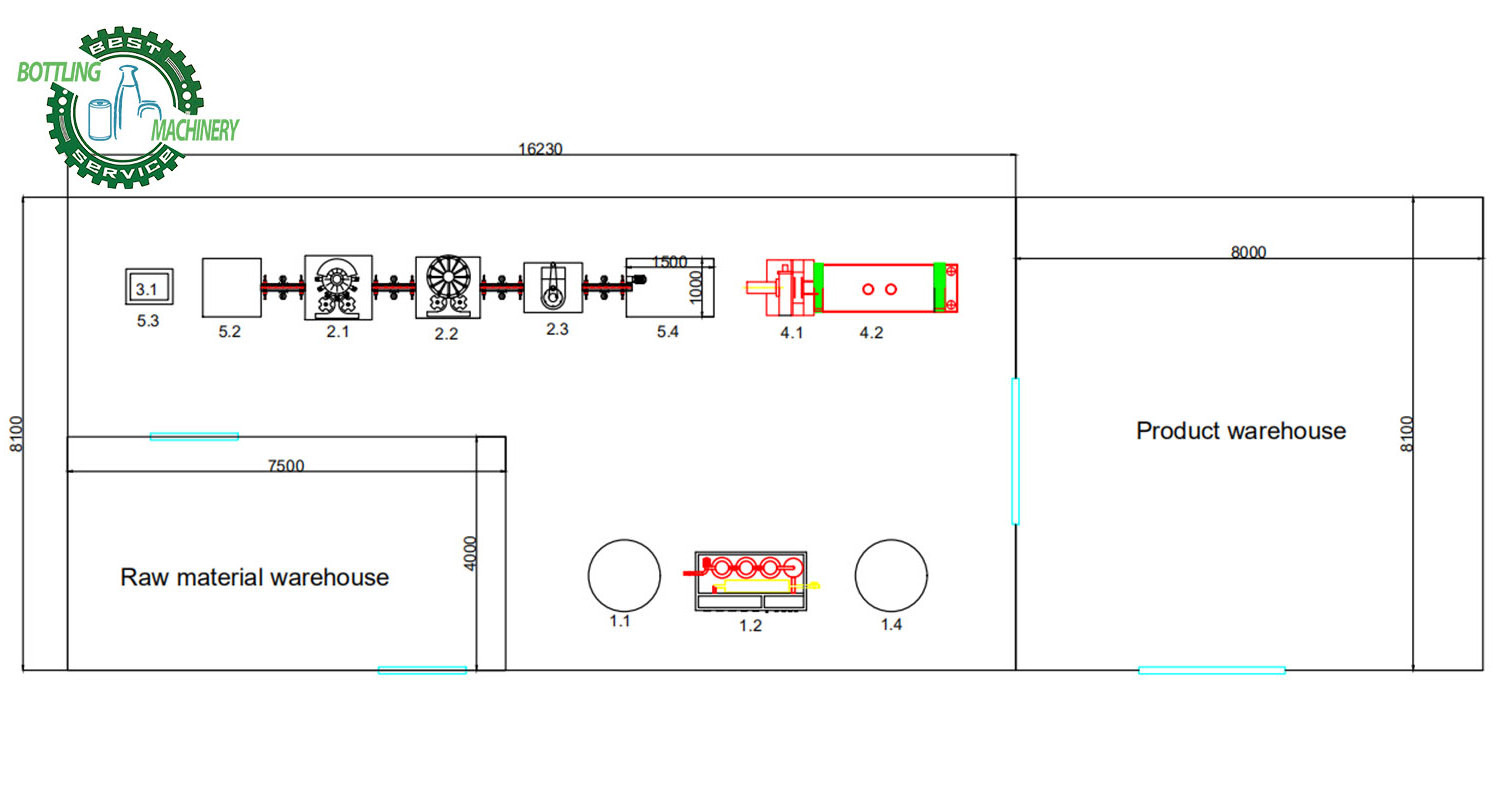

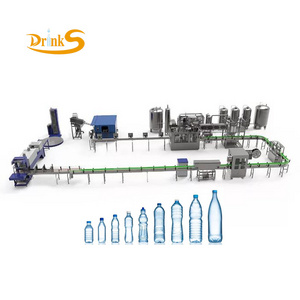

1.2, RO water treatment machine

2.1, 12-head washing machine

2.2, 12-head filling machine

2.3, 1-head screw capping machine

4.1, Semi-auto film shrink packing machine