- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

soontrue

-

Dimension(L*W*H):

-

3410x1700x3100mm

-

Weight:

-

600 KG

-

Core Components:

-

Other

Quick Details

-

Application:

-

Food, Beverage, Commodity, Chemical, Machinery & Hardware, APPAREL, Textiles, Cigarettes, Tobacco

-

Packaging Material:

-

Plastic

-

Voltage:

-

380V/3Ph/50Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

soontrue

-

Dimension(L*W*H):

-

3410x1700x3100mm

-

Weight:

-

600 KG

-

Core Components:

-

Other

|

Specifications

|

WP-20

|

|

|

|

|||

|

Pick-up speed

|

8 - 10 pcs/min(depends on the product)

|

|

|

|

|||

|

Pallet size range

|

L Max.1200mm; W Max. 1200mm; H Max150mm

|

|

|

|

|||

|

Max. palletizing height

|

2000mm (elevation column 600mm)

|

|

|

|

|||

|

Max. payload

|

30kg (including vacuum gripper)

|

|

|

|

|||

|

General power

|

3kw

|

|

|

|

|||

|

Power supply

|

380V/3PH/50Hz

|

|

|

|

|||

|

Air source

|

0.5 - 0.7 Mpa (air consumption 200 l/min)

|

|

|

|

|||

|

Manchine weight

|

600 kg

|

|

|

|

|||

|

Machine size

|

3410 x 1700 x 3100 mm

|

|

|

|

|||

Application:

Widely used in various industries such as food, household paper, beverages, pharmaceuticals, daily chemicals, electronics, and appliances.

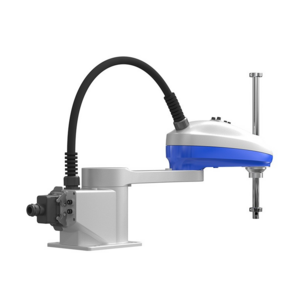

1.

Safe Collaboration:

Collaborative robots are designed with advanced safety features to ensure they can interact safely with humans. They are equipped with sensors that make them immediately stop or slow down if a human coworker is detected nearby to avoid accidents.

2. Simplicity and Ease of Use: Collaborative robots can be programmed easily, often even by staff lacking specialized IT knowledge. Their user-friendly interfaces enable simple instruction programming.

3. Flexibility: Collaborative robots can be easily moved, adapted, or reprogrammed to carry out different tasks or accommodate changes in the production line.

4. Efficiency and Productivity: Collaborative palletizing systems can work 24/7, excluding required maintenance, resulting in increased productivity. They can quickly adapt to handle new products and changes in volumes, offering a cost-effective solution for businesses.

5. Employee Health: By taking on some of the more physically demanding tasks, collaborative robots can help reduce the likelihood of injuries and strains, improving overall worker safety and wellbeing.

2. Simplicity and Ease of Use: Collaborative robots can be programmed easily, often even by staff lacking specialized IT knowledge. Their user-friendly interfaces enable simple instruction programming.

3. Flexibility: Collaborative robots can be easily moved, adapted, or reprogrammed to carry out different tasks or accommodate changes in the production line.

4. Efficiency and Productivity: Collaborative palletizing systems can work 24/7, excluding required maintenance, resulting in increased productivity. They can quickly adapt to handle new products and changes in volumes, offering a cost-effective solution for businesses.

5. Employee Health: By taking on some of the more physically demanding tasks, collaborative robots can help reduce the likelihood of injuries and strains, improving overall worker safety and wellbeing.

Foshan Soontrue Machinery Equipment Co., Ltd, established in 1993, is a leading manufacturer

engaged in the research & development, production, sales and service of Horizontal packing

machine, vertical packing machine and fully automatic packing system, which are mainly

applicable in bakery industry. Soontrue supplies more than 3000 packing solutions to customers all over the world every year.

Foshan Soontrue has grown into a company with more than 550 staffs and 41,000 square meters along with well improved factory management.

|

Q1:What type of machine for food packaging do you have?

|

|

|

|

|

||||

|

We will recommend suitable models based on your product characteristics, size, and type of placement, such as model with top film loader, bottom film loader, rotary end sealing, box motion end sealing, etc. In addition, different types of in-feed conveyors can also meet different types of products feeding methods, such as chain type, belt type, feeding-on-film type, etc.

|

|

|

|

|

||||

|

Q2:I'm worried that I don't know how to operate your machine

|

|

|

|

|

||||

|

Do not worry. Our machine for packaging is servo controlled, which greatly simplifies the difficulty of operation and

commissioning. Most of the daily operation of the machine can be conducted by a few start-stop buttons and HMI. If you have different products or packages that need to be changed, we can provide instructional videos to give you step-by-step tutorial. Also, the HMI has memory function, which is convenient for you to reload the settings in the future. |

|

|

|

|

||||

|

Q3: If I buy your automatic packaging machine, what technical support can I get?

|

|

|

|

|

||||

|

We have professional technical engineers to give you on line support. We can provide you with instructional videos for the installation and daily commissioning and maintenance. Online video call tutorial is also available for special cases.

For some custom-made solutions, our experienced after-sales technicians can also provide on-site installation and commissioning services on buyers cost (except special period, such as COVID-19). |

|

|

|

|

||||

|

Q4:How do we build trust in the first business?

|

|

|

|

|

||||

|

We believe that a win-win business must be based on our professional services and excellent products. Our team will fully study your needs, and clearly explain our products and solutions to you so that you can understand our services. We can take you to visit our modern factory through a video call, so that you can understand how your machine will be produced and let you know more about our products. Before delivery, we can cooperate with your partners to carry out factory acceptance test, or carry out acceptance through test video or video call. Make sure that the high quality packaging machine you need is ready before shipment.

|

|

|

|

|

||||

|

Q5: How can I find the custom packaging machine I need?

|

|

|

|

|

||||

|

We will fully communicate of the information of your products, packaging scheme, and feeding method. We have nearly 30 years of experience as an packaging machine factory and can provide you with similar case videos for your reference. If necessary, we will ask you for samples of products and packaging films for testing, in order to find the most suitable and cost-effective solution for you.

|

|

|

|

|

||||

Hot Searches