- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

40 Window / per day

-

Power:

-

2.2kw

-

Dimension(L*W*H):

-

1300*1200*1300mm

-

Model:

-

LMB-A-120

-

Input voltage:

-

380V 50Hz

-

Input power:

-

2.2kw

-

Air pressure:

-

0.4~0.6MPa

-

Air consumption:

-

20L/Time

-

Oil capacity:

-

20L

-

Profile width:

-

≤120mm

-

Combining cylinder movement:

-

98mm

-

Locator adjustment range:

-

80mm

-

Overall dimension:

-

1300x1200x1300mm

Quick Details

-

Brand Name:

-

YUEFENG

-

Voltage:

-

380V/ 50Hz

-

Weight:

-

600 kg

-

Production Capacity:

-

40 Window / per day

-

Power:

-

2.2kw

-

Dimension(L*W*H):

-

1300*1200*1300mm

-

Model:

-

LMB-A-120

-

Input voltage:

-

380V 50Hz

-

Input power:

-

2.2kw

-

Air pressure:

-

0.4~0.6MPa

-

Air consumption:

-

20L/Time

-

Oil capacity:

-

20L

-

Profile width:

-

≤120mm

-

Combining cylinder movement:

-

98mm

-

Locator adjustment range:

-

80mm

-

Overall dimension:

-

1300x1200x1300mm

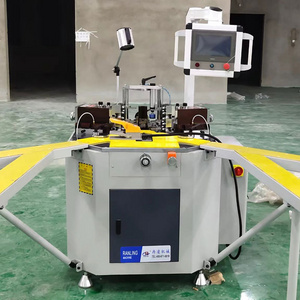

>>>Jinan Yuefeng Machinery Co., Ltd founded in 1983, a professional manufacturer specialized in producing PVC and Aluminum win-door equipment, curtain wall equipment and insulating glass equipments, we are the foremost pioneet in the win-door industry.

>>>Yuefeng has a fully equipped machining center and highly qualilfied technicians. With the year of effort and the support from all strata of the society, we are becoming stronger. It is specializing in developing and manufacturing PVC & aluminum window and doors machines, curtain-wall machines, insulating glass machines, and milling machines. It is the most powerful champion and promoter in the win-door industry. Our products exported to Middle East, Russia, South Africa, Vietnam, India, srilanka us, and South America etc., and deeply favored by the customers.

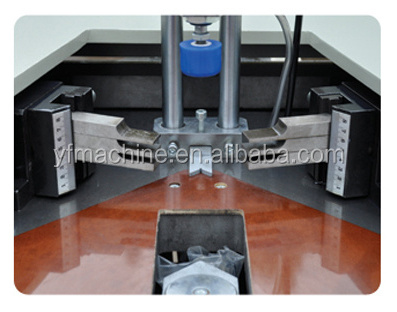

LMB-A-120 Aluminum Corner Crimping Machine

♦ Used for 90°corner combining.

♦ Adjustable corner combining tool that achieve multi-position corner combining.

♦ Inner locator can sit below the worktable, easy operation.

♦ Hydraulic system supplied large punching and riveting force.

♦ Left and right punching heads adopt hard synchronous feeding device, thus makes the connection more firmly.

♦ It has features of easy operation, reliable performance and convenient maintenance.

|

Model |

LMB- A- 120 |

|

Input voltage |

380V 50Hz |

|

Input power |

2.2 kw |

|

Air pressure |

0.4~0.6MPa |

|

Air consumption |

20L/ Time |

|

Oil capacity |

20L |

|

Profile width |

≤120mm |

|

Combining cylinder movement |

98mm |

|

Locator adjustment range |

80 mm |

|

Overall dimension |

1 3 00×1 2 00×1300mm |

| Automatic Insulating Glass Flat-Pressing Production Line | Glass Edge Polishing Machine |

>>>.Glass Curtain Wall Machine.

>>>.Arc Bending Machine

>>>.Corner Crimping Machine

>>>.Glass Edging Machine

>>>.Glass washing Machine

>>>.Butyl Coating Machine

>>>.Two-component Extruder Machine

>>>.Insulating Glass Machine

>>>.End Milling Machine

>>>.Machining Center

>>>.Welding Machine

>>>.Cutting Machine

>>>.Insulating Glass Solution

>>>.Aluminum Window and Door Solution

>>>.Upvc Window and Door Solution

1.The biggest aluminium construction frame factory in india. Sharp engineer. They have been using this three axis machining center for more than 7 years.

2. Regular customer in coimbatore in india frist line bought in 2014, second line bought 2019

3. Amrica customer factory

1.Are your company a trading one or a factory?

Factory + trade (integration),

36

years' focusing on

Upvc,Aluminum Window and Doors Equipment ,insulating glass equipment and curtain wall equipment.

2. After an order is placed, when to deliver?

♦ Generally about

15

days, If we have inventory, we can arrange shipment within

5

days.

♦

Please be aware that our production lead times depend on specific items and item quantities.

3.What about the services and product' quality?

♦

Each

machine

must be carried out 100% quality examination and test

before shipment

.

♦ And all machines meet ISO and CE certification.