- Product Details

- {{item.text}}

Quick Details

-

Tolerance:

-

±1%

-

Steel Grade:

-

301L, S30815, 301, 304N, 310S, 316Ti, 316L, 316, 321, 410S, 314, 347, 304, 304L, 370, 305

-

Surface Finish:

-

2B

-

Place of Origin:

-

China

-

Application:

-

elevator pipe fittings

-

Product name:

-

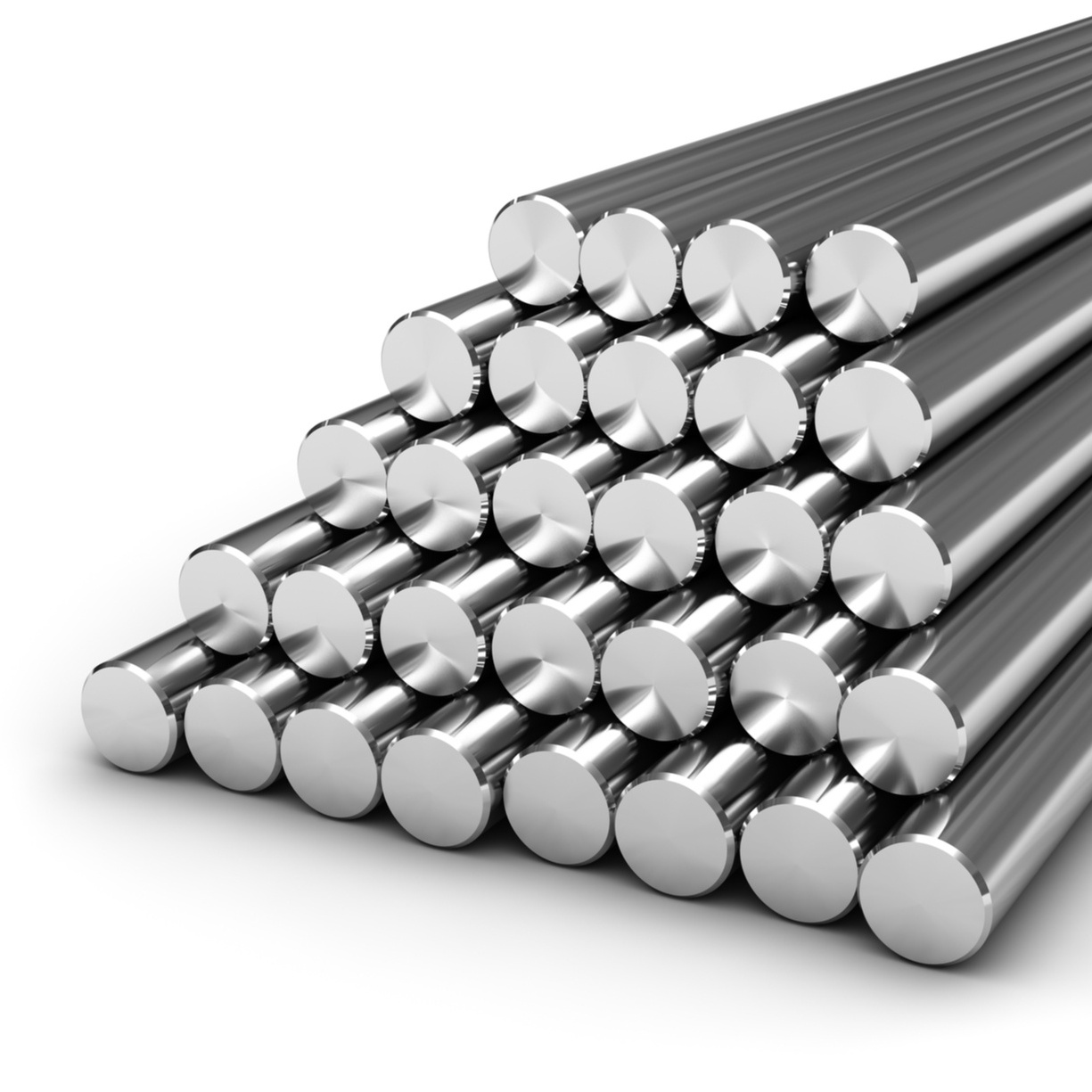

Stainless Steel Round Bar Rod

-

Keyword:

-

Hot Rolled Alloy Steel Round Bar

-

Technique:

-

Cold Drawn Hot Rolled Forged

-

Surface:

-

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D

-

Material:

-

201/202/303/304/304L/316/316L/2205

-

MOQ:

-

1 Ton

-

Packing:

-

Standard Seaworthy Package

-

Payment Term:

-

L/C T/T (30%DEPOSIT)

-

Technology:

-

Hot Formed Cold Formed

-

Certification:

-

ISO9001

Quick Details

-

Standard:

-

AiSi

-

Grade:

-

300 Series

-

Shape:

-

Round

-

Tolerance:

-

±1%

-

Steel Grade:

-

301L, S30815, 301, 304N, 310S, 316Ti, 316L, 316, 321, 410S, 314, 347, 304, 304L, 370, 305

-

Surface Finish:

-

2B

-

Place of Origin:

-

China

-

Application:

-

elevator pipe fittings

-

Product name:

-

Stainless Steel Round Bar Rod

-

Keyword:

-

Hot Rolled Alloy Steel Round Bar

-

Technique:

-

Cold Drawn Hot Rolled Forged

-

Surface:

-

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D

-

Material:

-

201/202/303/304/304L/316/316L/2205

-

MOQ:

-

1 Ton

-

Packing:

-

Standard Seaworthy Package

-

Payment Term:

-

L/C T/T (30%DEPOSIT)

-

Technology:

-

Hot Formed Cold Formed

-

Certification:

-

ISO9001

Products Description

Stainless Steel Angle Support Bar 5mm Stainless Steel Angle Bar

Jianglin stainless steel is a professional supplier and manufacturer of stainless steel bar

Stainless steel bar is a type of steel that contains both austenitic and ferritic phases in its microstructure. This

combination of phases gives it excellent corrosion resistance, high strength, and good weldability. Duplex stainless steel bars.are commonly used in industries such as oil and gas, chemical processing, and marine engineering.

The most commonly used grades of duplex stainless steel bars are:2205, 2507 ,2304

Duplex stainless steel bars are available in various sizes and shapes, including round bars, square bars, and hexagonal bars. They can also be customized to meet specific requirements.

Welcome inquiry to us to get a free price list everyday.

Stainless steel bar is a type of steel that contains both austenitic and ferritic phases in its microstructure. This

combination of phases gives it excellent corrosion resistance, high strength, and good weldability. Duplex stainless steel bars.are commonly used in industries such as oil and gas, chemical processing, and marine engineering.

The most commonly used grades of duplex stainless steel bars are:2205, 2507 ,2304

Duplex stainless steel bars are available in various sizes and shapes, including round bars, square bars, and hexagonal bars. They can also be customized to meet specific requirements.

Welcome inquiry to us to get a free price list everyday.

Details Images

Chemical Analysis Specified

|

Chemical Analysis (%) Specified

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Grade

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

Ni

|

Others

|

|||||||||

|

201

|

0.15

|

1

|

8~11

|

0.06

|

0.03

|

15~17

|

-

|

0.9~1.5

|

N 0.2

|

|||||||||

|

202

|

0.15

|

1

|

7.5~10

|

0.06

|

0.03

|

17~19

|

-

|

4~6

|

N 0.25

|

|||||||||

|

301

|

0.15

|

1

|

2

|

0.045

|

0.03

|

16~18

|

-

|

6~8

|

N 0.1

|

|||||||||

|

304

|

0.08

|

1

|

2

|

0.035

|

0.03

|

18~20

|

-

|

8~10

|

N 0.1

|

|||||||||

|

304L

|

0.03

|

1

|

2

|

0.035

|

0.03

|

18~20

|

-

|

9~13

|

N 0.1

|

|||||||||

|

309S

|

0.08

|

1

|

2

|

0.045

|

0.03

|

22~24

|

-

|

12~15

|

-

|

|||||||||

|

310S

|

0.08

|

1.5

|

2

|

0.035

|

0.03

|

24~26

|

-

|

19~22

|

-

|

|||||||||

|

316

|

0.08

|

1

|

2

|

0.045

|

0.03

|

16~18

|

2~3

|

10~14

|

N 0.1

|

|||||||||

|

316L

|

0.03

|

1

|

2

|

0.045

|

0.03

|

16~18

|

2~3

|

10~14

|

N 0.1

|

|||||||||

|

317L

|

0.03

|

1

|

2

|

0.045

|

0.03

|

18~20

|

3~4

|

11~15

|

-

|

|||||||||

|

321

|

0.08

|

1

|

2

|

0.045

|

0.03

|

17~19

|

-

|

9~12

|

Ti ≥5×C%

|

|||||||||

|

347

|

0.08

|

1

|

2

|

0.045

|

0.03

|

17~20

|

-

|

9~13

|

Nb ≥10*C

|

|||||||||

|

409L

|

0.3

|

1

|

1

|

0.04

|

0.02

|

10.5~11.7

|

-

|

0.6

|

N 0.03 Ti 0.15~0.5 Nb 0.1

|

|||||||||

|

410

|

0.15

|

1

|

1

|

0.04

|

0.03

|

11.5~13.5

|

-

|

-

|

-

|

|||||||||

|

410S

|

0.08

|

1

|

1

|

0.04

|

0.03

|

11.5~13.5

|

-

|

0.6

|

-

|

|||||||||

|

420J2

|

0.26~0.35

|

1

|

1

|

0.035

|

0.03

|

12~14

|

-

|

0.6

|

-

|

|||||||||

|

430

|

0.12

|

0.75

|

1

|

0.04

|

0.03

|

16~18

|

-

|

0.6

|

-

|

|||||||||

|

441

|

0.75~0.95

|

1

|

0.6

|

0.04

|

0.03

|

16~18

|

0.75

|

-

|

-

|

|||||||||

|

443

|

0.01

|

-

|

-

|

-

|

-

|

21

|

-

|

-

|

Ti 0.3

|

|||||||||

|

444

|

0.025

|

1

|

1

|

0.04

|

0.03

|

17.5~19.5

|

1.75~2.5

|

1

|

N ≤0.035 Ti+Nb:≥0.2+4

|

|||||||||

|

Others

|

|

|

|

|

|

|

|

|

|

|||||||||

Product packaging

Hot Searches