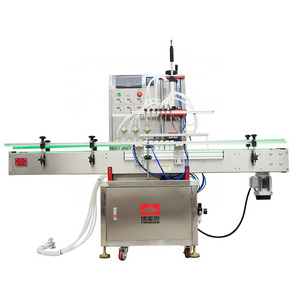

Simple operation panel,it can be customized in different kinds of language.

The visual working data makes it easier to test and adjust the machine helps to save time. We use imported operation panel which

improves the product quality.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

2 ml

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Mingstar

-

Dimension(L*W*H):

-

1600*2100*2200MM

-

Weight:

-

2500 KG

-

After Warranty Service1:

-

Video technical support

-

After Warranty Service2:

-

Online support

-

Local Service Location:

-

None

-

After-sales Service Provided1:

-

Online support

-

After-sales Service Provided2:

-

Video technical support

-

After-sales Service Provided3:

-

Free spare parts

-

After-sales Service Provided4:

-

Field installation, commissioning and training

-

After-sales Service Provided5:

-

Field maintenance and repair service

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Machinery Capacity:

-

4000BPH, 5000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Water, Juice

-

Filling Accuracy:

-

2 ml

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Mingstar

-

Dimension(L*W*H):

-

1600*2100*2200MM

-

Weight:

-

2500 KG

-

After Warranty Service1:

-

Video technical support

-

After Warranty Service2:

-

Online support

-

Local Service Location:

-

None

-

After-sales Service Provided1:

-

Online support

-

After-sales Service Provided2:

-

Video technical support

-

After-sales Service Provided3:

-

Free spare parts

-

After-sales Service Provided4:

-

Field installation, commissioning and training

-

After-sales Service Provided5:

-

Field maintenance and repair service

-

Marketing Type:

-

Ordinary Product

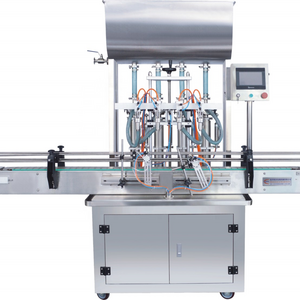

Product Description

Automatic 3 in 1 water PET bottle filling capping machine

This CGF series bottling machine, incorporates rinsing, filling and capping. into one and is a kind of full-automatic equipment. It is innovated and designed in the requirement of still pure water and mineral water, on the bases of introducing, digesting and absorbing advanced technology from Germany and Italy.

CGF series bottle water filling machine is used to fill mineral water, pure water, purified water, spring water into PET bottle

from 200ml-2000ml. Glass bottle is also suitable, just need to change the conveyor parts.

Different models can satisfy various requirement of output from 3000B/H to 36000B/H.

The whole process of water filling production line is automatic, suitable for PET bottle, plastic bottle filling mineral water and pure water.

Rinsing

Filling

Capping

Main Technical Parameters

Take water as the main parameter for reference, other liquids, please contact customer service for details

All machines could be customized , we could design design and produce machines according to your request.

|

Model

|

CGF8-8-3

|

CGF14-12-5

|

CGF16-16-5

|

CGF24-24-6

|

|

Production capacity

|

3000BPH(500ml)

|

5000BPH(500ml)

|

8000BPH(500ml)

|

12000BPH(500ml)

|

|

Washing heads

|

8

|

14

|

16

|

24

|

|

Filling heads

|

8

|

12

|

16

|

24

|

|

Capping heads

|

3

|

5

|

5

|

6

|

|

Suitable bottle

|

PET bottle,

Plastic bottle

|

PET bottle,

Plastic bottle

|

PET bottle,

Plastic bottle

|

PET bottle,

Plastic bottle

|

|

Diameter of bottle

|

50-110mm

|

50-110mm

|

50-110mm

|

50-110mm

|

|

Height of bottle

|

150-310mm

|

150-310mm

|

150-310mm

|

150-310mm

|

|

Suitable cap

|

Plastic screw cap

|

Plastic screw cap

|

Plastic screw cap

|

Plastic screw cap

|

|

Weight

|

1500KG

|

2000KG

|

4500KG

|

6000KG

|

|

Main motor power

|

1.5KW

|

1.5KW

|

3KW

|

3KW

|

This Production Line is a whole Automatic water filling capping machine production line solution;The Machine Type, Number Of Machines, Speed, Capacity, Size, Etc. Of The Production Line Would Be Customized According To The Customer'S Production Needs; We Can Develop A Professional Integrated Filling And Packaging Production Line Plan For The Customer.

Please contact us to confirm the product parameter before payment.

Detailed Images

Operation Panel

The total machine uses advanced photoelectric detection technology to detect each parts operation status, no bottle no filling, and no bottle no capping, automatic and easy operation.

Washing Parts

Into bottle way is air conveyor direct connection with bottle dial.All

-304/316 stainless steel rinse heads,water spray style inject design, more save water consumption and more clean.

-304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

-304/316 stainless steel washing pump make the machine more durable.

-304/316 stainless steel rinse heads,water spray style inject design, more save water consumption and more clean.

-304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

-304/316 stainless steel washing pump make the machine more durable.

Filling Parts

- 304/316 Stainless steel high precision filling nozzle

- Filling volume adjustable in fine rank, same liquid level after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

- 304/316 stainless steel filling pump

- Efficient spray nozzle rinse thoroughly and save water for flushing

- Filling volume adjustable in fine rank, same liquid level after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

- 304/316 stainless steel filling pump

- Efficient spray nozzle rinse thoroughly and save water for flushing

- Place and capping system, electromagnetic capping heads, with burden discharge

function, make sure minimum bottle crash during capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

function, make sure minimum bottle crash during capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

Related Products

About Mingstar

About Mingstar

1 / Standardized workshop of total 2000 square meters.

2 / The equipment will be tested and run for 24 hours before leaving the factory, to ensure

the smooth working of water pipeline,and pneumatic, electrical and mechnical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

About Mingstar

<1> Standardized workshop of total 2000 square meters.

Different types of processing units, such as water jet cutter, plasma cutter, laser cutter, CNC machine from Taiwan chevalier &Korea Daewoo, ensure the precision of parts.

<2>The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechanical stability.

<3>Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

<4>Engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers’ requirements to save space.

<5>Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

Certificate

International certification, National Certificate of equipment verification are done in Mingstar .

Verification Certificates of equipments: ISO9001:2015; CE Certificate , SGS , National Certificate of equipment verification,etc.

Mingstar Serivce

*7/24 Online Service::Machine running video / Watch our factory online / More service contact us

*Sucessful Beverage Plant::Supply a running beverage line in your country , you can see machine runing directly.

*Installation / Debug / Training:

1 - We will arrange seasoned technician for equipments installation, debug and test production.

2 - Our company offers technology training to the customer in his factory.

3 - We promise that our goods are all new and not used.

*After-sales Service:

1 - After checking, we offer 12 months as a quality guarantee, free offer wearing parts and offer other parts at the lowest price.

2 - If you could not solve the problems, we will arrange a technician to your factory solving the problems.

3 - After quality guarantee, we offer technical support and after-sales service.

Partner Customers

Mingstar is a professional manufacturer of beverage machinery in China.

With the scientific progressive conception of rapid introduction, we make our machinery cover all over the overseas market. We have been producing our goods with mature techniques and first-class quality. We warmly welcome customers all over the world to visit our manufacture.

Customer Reviews

Cooperative Customer Brands

With years of export experience along with excellent quality, advanced services and competitive prices,

Mingstar has won numerous customers' trust and support.

What We Offer?

Consultation Service

Filling Machine Choosing

Filling Machine Customization

Filling Line Updating

Turn-Key Solution

Manufacture & Test Service

Filling Machine Stress Testing

Packing & Logistic

SGS Certification

Technical Support

After Sales Service

Installation & Worker Training

Technical Support Online

Annual Diagnosis & Updating

Optional Value-added Service

Agent Recruitment Programme

Client Guarantee Programme

Customer Development Programme

Label Design.

We can provide the label design

according to the bottle size, the

icon style you want.

Bottle Design.

Our designers can design bottle

styles according to your

requirement.

Machine Layout.

We will design andconfirm the

machine layout according to

your factory sketch.

Packing& Delivery

Packing Details : Plastic film and wooden case packaging, double protection

Delivery Details : Delivery within 30 days by sea Twoyears warranty after receiving the equipment .

FAQ

Q:HOW TO ENSURE THE QUALITY OF FILLING MACHINE?

※In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment.

※Each component before assembly needs strictly control by inspecting personnel.

※Each assembly is in charged by a master who has working experience for more than 6 years.

※After all the machines are completed, we will connect them together and run the full production line for at least 12 hours to ensure the stable running in clients' factory.

※We offer whole filling line testing production service in our factory for hours by request.

※Each component before assembly needs strictly control by inspecting personnel.

※Each assembly is in charged by a master who has working experience for more than 6 years.

※After all the machines are completed, we will connect them together and run the full production line for at least 12 hours to ensure the stable running in clients' factory.

※We offer whole filling line testing production service in our factory for hours by request.

Q: WHAT WARRANTY OF FILLING MACHINE CAN I GET FROM MINGSTAR?

※Two years warranty after receiving the equipment . Free spare parts and technical supports.

※New client guarantee programme offers longer warranty and customized after service.

※Local after service network is under construction.

※Annual engineer visiting for diagnosis and updating service.

※New client guarantee programme offers longer warranty and customized after service.

※Local after service network is under construction.

※Annual engineer visiting for diagnosis and updating service.

Q: ANY OTHER QUESTIONS?

※Send inquiry to Mingstar.

※Chat now through Alibaba APP.

※Call us or reserve a call.

※Chat now through Alibaba APP.

※Call us or reserve a call.

Hot Searches