- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Customized

-

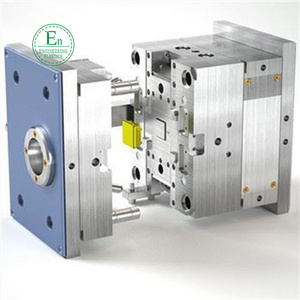

Cavity/core steel:

-

S136, 2344

-

Mould base:

-

LKM

-

Design software:

-

UG, Soildworks, AutoCAD

-

Runner:

-

Cold Runner

-

Post- treatment:

-

printing

-

Mould life:

-

50,000 shots

-

Color:

-

per pantone code

-

Gate type:

-

Side gate,Sub Gate,Pin point gate,Fan gate,Direct gate

-

Mold Base:

-

LKM,HASCO,DME

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Model Number:

-

Customized

-

Cavity/core steel:

-

S136, 2344

-

Mould base:

-

LKM

-

Design software:

-

UG, Soildworks, AutoCAD

-

Runner:

-

Cold Runner

-

Post- treatment:

-

printing

-

Mould life:

-

50,000 shots

-

Color:

-

per pantone code

-

Gate type:

-

Side gate,Sub Gate,Pin point gate,Fan gate,Direct gate

-

Mold Base:

-

LKM,HASCO,DME

Business Scope:

1. Product design and development, ODM, OEM.

2. Scanning data. (Get 3D drawing per your delivered sample)

3. Drawing re-construction. (Simple design is free)

4. Injection molding for the plastic shell of your product.

5. CNC machining service. (metal, plastic, wood)

6. Mass production. (Unit price will be very cheap)

Company profile

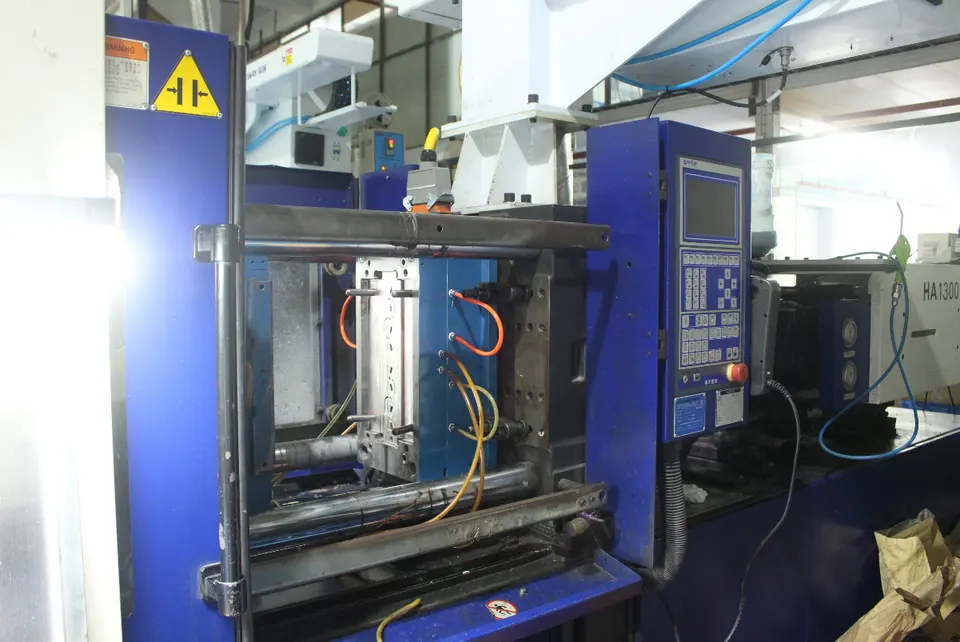

SMARTMOLDTECH ,established in 1995,has been always devoting to plastic injection molding,CNC machining, and manufacture over past 20 years.

Legrand, VIVO Motorola, TCL Philips ZTE, Parrot

have been our long-term cooperation customers.

Feel free to send your inquiry to get a quote and contact with us for a visit to our factory!

CNC Machining

1. CNC machining for metal and plastic

2. CNC production

3. CNC prototyping for metal and plastic

4. CNC wood

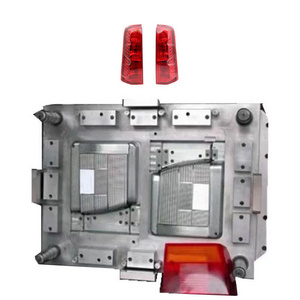

Plastic Injection

1. Two and Three plate mold

2. Double injection molding

3. Hot runner molding

3. Overmolding

4. Export mold

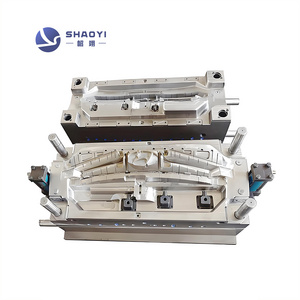

Mass production

1. Small volume production

2. Big volume production.

1. Material options: PC ABS POM PP etc.

2. Post-treatment: oil painting, silk screen printing, pad printing, laser engraving, sand blasting, powder coating

3. Mold base standard: LKM

4. Surface finish: Polishing

5. Color options: Per pantone code

6. Certification: ISO9001

injection molding plastic parts

1. We have 12 engineers supporting your project.

2. We have 5 CNC center and 100 injection machines, 20 EDM, 3 W-EDM to ensure the best manufacturing quality

Feel free to send us the E-mail or pay a visit to our factory.

|

Place of Origin

|

China

|

|

|

|

|

||||

|

Model Number

|

customized

|

|

|

|

|

||||

|

Shaping Mode

|

Plastic Injection Mould

|

|

|

|

|

||||

|

Product Material

|

Plastic

|

|

|

|

|

||||

|

Plastic Material

|

ABS, PP, PC, PA, POM, PE, PU, PVC, PBT, PMMA, etc

|

|

|

|

|

||||

|

Application

|

Auto parts, machinery parts, household parts, Cooker parts, furniture parts, etc

|

|

|

|

|

||||

|

Runner

|

cold runner/hot runner

|

|

|

|

|

||||

|

Mould material

|

NAK80, S136, 738H, 718H, 2344, P20, etc

|

|

|

|

|

||||

|

Sprue Gate

|

YUDO runner, Pin-point gate, Sub gate, Edge gate, Open gate, etc

|

|

|

|

|

||||

|

Surface treatment

|

Matte/Smooth/ Polsihed

|

|

|

|

|

||||

|

Moud base

|

LKM/DME/HASCO

|

|

|

|

|

||||

|

Mould Cavity

|

Singe or multi as your requirement

|

|

|

|

|

||||

|

Design Software

|

Catia, Solidworks, CROE/PROE, UG, CAD, CAXA, etc

|

|

|

|

|

||||

|

Moild Life

|

300K-1,000K shots

|

|

|

|

|

||||

|

tolerance

|

+/- 0.01-0.02mm

|

|

|

|

|

||||