- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Taiwan

-

Brand Name:

-

FASTFIX-IT

-

Model Number:

-

FX-ST501H

-

Type:

-

Epoxy putty

-

Material:

-

Epoxy putty

-

%Solid by volume:

-

100

-

Specific gravity:

-

2.36gm/cm3

-

Cure shrinkage:

-

0.0006cm/cm

-

Hardness shore D:

-

85

-

Adhesive tensile shear:

-

20 MPa

-

Tensile stength:

-

22.5MPa

-

Modulus of elasticity:

-

1900MPa

-

Compressive strength:

-

55MPa

-

Co-efficient of Thermal Expansion:

-

86 x 10-6 °C-1

Quick Details

-

CAS No.:

-

3214109000-5

-

Other Names:

-

Epoxy Putty

-

MF:

-

Mixture

-

Place of Origin:

-

Taiwan

-

Brand Name:

-

FASTFIX-IT

-

Model Number:

-

FX-ST501H

-

Type:

-

Epoxy putty

-

Material:

-

Epoxy putty

-

%Solid by volume:

-

100

-

Specific gravity:

-

2.36gm/cm3

-

Cure shrinkage:

-

0.0006cm/cm

-

Hardness shore D:

-

85

-

Adhesive tensile shear:

-

20 MPa

-

Tensile stength:

-

22.5MPa

-

Modulus of elasticity:

-

1900MPa

-

Compressive strength:

-

55MPa

-

Co-efficient of Thermal Expansion:

-

86 x 10-6 °C-1

Production Name:

Steel-filled epoxy putty

Product Code:

FX-ST501H

Product Description:

Steel-filled epoxy putty cures at room temperature and is designed for filling, rebuilding and bonding metal surfaces.

Usage:

.Repair areas where welding or brazing would be undesirable or impossible.

.

Repair of very weak metals.

.

Iron repair and molding

.

Rebuilding pump and valve bodies.

Advantages:

1.

Repair areas where welding or brazing would be undesirable or impossible.

2.

Repair of very weak metals.

3.

Iron repair and molding

4. Rebuilding pump and valve bodies

How to Use:

STEP1. PREPARATION

Properly clean the surface for preparation. Surfaces should be clean, dry, free from oils and rough.

STEP2. MIXING

Ideal application temperature is 13°C - 32°C. Under cold conditions, prepare the repair area, 38°C - 43°C is recommended to dry

off any moisture, contamination, or solvents, as well as to assist epoxy in achieving maximum adhesion properties.

STEP3. APPLICATION

Spread mixed material over the repair area and work firmly into the substrate to ensure maximum surface contact. Steel-filled

epoxy putty FX-ST501H full cure is 16 hours, can be machined, drilled, or painted.

Where to Use:

|

SUBSTANCES OF CHEMICAL RESISTANCE

|

|

|

|

HIGH RESISTANCE

|

1,1,1 Trichloroethane, Ammonia, Cutting Oil, Petrol (Unleaded), Petrol (Unleaded), Hydrochloric 10%, Kerosene, Phosphoric 10%, Potassium Hydroxide 20%, Sodium Chloride BrineSodium Hydroxide 10%, Sulphuric 10%, Trisodium Phosphate

|

|

|

LOW

RESISTANCE |

Methyl Ethyl Ketone, Methylene Chloride, Sulphuric 50%

|

|

|

MEDIUM

RESISTANCE |

Xylene

|

|

|

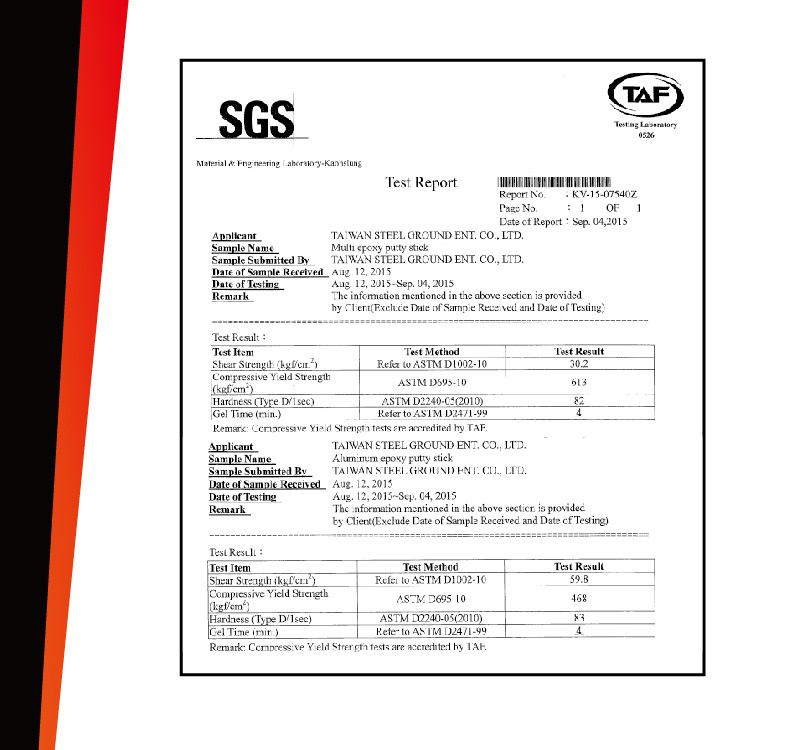

Test Item

|

Test Result

|

|

%Solid by volume

|

100

|

|

Tensile strength

|

432cm3/kg

|

|

Mixed Viscosity

|

Putty

|

|

Specific Gravity

|

2.36 gm/cm3

|

|

Cure Shrinkage

|

0.0006 cm/cm

|

|

Hardness Shore D

|

85

|

|

Adhesive Tensile Shear

|

20 MPa

|

|

Tensile Strength

|

22.5 MPa

|

|

Compressive Strength

|

55 MPa

|

|

Modulus of Elasticity

|

1900 MPa

|

|

Co-efficient of Thermal Expansion

|

86 x 10-6 °C-1

|

|

Thermal Conductivity

|

1.37 x 10-3 cal.cm/sec/cm2.°C

|

|

Dielectric Strength

|

1175 volts/mm

|

|

Dielectric Constant

|

68

|

Shipping:

By sea/ air/ courier. (FOB Kaohsiung)

Courier includes DHL, FedEx, TNT, EMS, etc.