- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

1000 mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

raymax

-

Weight (KG):

-

9000

-

Motor Power (kw):

-

15 kw

-

Application:

-

Stainless Plate Bending

-

Color:

-

Customizable

-

Material:

-

Metal Steel Sheet

-

CNC System:

-

Delem Hydraulic CNC Press Brake

-

Usage:

-

Metal Sheet Folding

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

3200

-

Slider Stroke (mm):

-

200 mm

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

1000 mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

raymax

-

Weight (KG):

-

9000

-

Motor Power (kw):

-

15 kw

-

Application:

-

Stainless Plate Bending

-

Color:

-

Customizable

-

Material:

-

Metal Steel Sheet

-

CNC System:

-

Delem Hydraulic CNC Press Brake

-

Usage:

-

Metal Sheet Folding

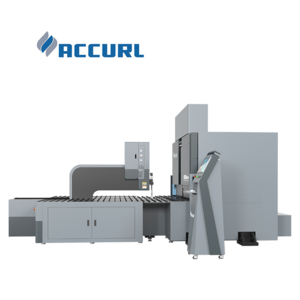

Feature

1. The frame is steel structure, left and right vertical plate, table and pressure plate welded into a unitary structure, after welding to eliminate internal stress by tempering, exceptional rigidity, high stability.

2. Important parts of the frame, sliders, etc. are used ANSYS finite element analysis software to ensure machine reliability.

3. Hydraulic drive, cylinder on both end of machine, disposed on the slider to drive it work directly.

4. The stroke of cylinder ( Y1,Y2 ) and back gauge ( X, Y, Z ) are computer controlled. The back guage adopt ball screw and rolling guideway, ensuring a high accuracy of repetition.

5. Back Gauge size and slide stroke controlled by CNC system, back gauge with high precision ball screw, stable operation and precise positioning.

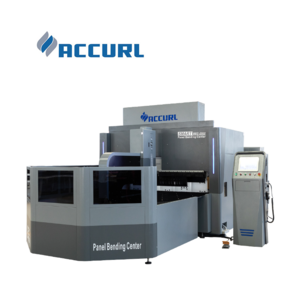

Standard Configuration

CNC DELEM DA66T with 2D colour graphics

Main Motor Siemens Germany brand

Pump First USA brand

Light Curtain KELI brand

Hydraulic Valve BOSCH-REXROTH Germany brand

Foot Pedal Italy Pizzato brand

Electrical Schneider France brand

Ball Screw& Linear guide Hiwin Taiwan brand

Fast Clamping

|

Type

|

Nominal pressure (KN)

|

Workbench length (mm)

|

Workbench width (mm)

|

Poles distance (mm)

|

Throat depth (mm)

|

Main motor (kw)

|

Dimensions L*W*H (mm)

|

|

40*1600

|

400

|

1600

|

900

|

1165

|

350

|

5.5

|

2250*1650*2400

|

|

63*2500

|

630

|

2500

|

900

|

1960

|

380

|

5.5

|

3150*1700*2500

|

|

80*2500

|

800

|

2500

|

900

|

1960

|

380

|

7.5

|

3150*1700*2500

|

|

80*3200

|

800

|

3200

|

900

|

2760

|

380

|

7.5

|

3850*1700*2500

|

|

100*3200

|

1000

|

3200

|

950

|

2750

|

390

|

7.5

|

3900*1800*2650

|

|

125*3200

|

1250

|

3200

|

950

|

2750

|

390

|

11

|

3900*1800*2680

|

|

160*3200

|

1600

|

3200

|

1000

|

2740

|

400

|

15

|

4000*1900*2720

|

|

200*3200

|

2000

|

3200

|

1000

|

2730

|

400

|

18.5

|

4000*1900*2720

|

|

300*3200

|

3000

|

3200

|

1330

|

2720

|

500

|

22

|

4000*2200*3500

|

|

100*4000

|

1000

|

4000

|

950

|

3350

|

390

|

7.5

|

4800*1800*2650

|

|

125*4000

|

1250

|

4000

|

950

|

3350

|

390

|

11

|

4800*1800*2680

|

|

160*4000

|

1600

|

4000

|

1000

|

3340

|

400

|

15

|

4800*1900*2720

|

|

200*4000

|

2000

|

4000

|

1000

|

3330

|

400

|

18.5

|

4800*1900*2800

|

|

250*4000

|

2500

|

4000

|

1000

|

3330

|

450

|

18.5

|

4800*1900*2850

|

|

300*4000

|

3000

|

4000

|

1330

|

4920

|

500

|

22

|

4800*1950*2900

|

|

200*6000

|

2000

|

6000

|

1000

|

4940

|

400

|

18.5

|

6800*1900*2800

|

|

250*6000

|

2500

|

6000

|

1050

|

4930

|

450

|

18.5

|

6800*1900*2850

|

|

300*6000

|

3000

|

6000

|

1330

|

4920

|

500

|

22

|

6800*1950*2900

|

|

400*6000

|

4000

|

6000

|

1350

|

4920

|

500

|

37

|

6800*2000*2950

|

|

500*6000

|

5000

|

6000

|

1350

|

4910

|

500

|

45

|

6800*2050*3000

|

Using mechanical fast clamp for upper dies, changing dies more convenient and safe.

Ensuring good bending strength and precision.

The stop finger can move smoothly on the linear guide and can be adjusted up and down,

which is convenient, efficient and easy to control.

which is convenient, efficient and easy to control.

Hydraulic transmission with high reliability, integrated hydraulic system can effectively alleviate problems caused by leakage of hydraulic fluid.

INOVANCE Servo Motor

Replace the original Siemens motor

40% power saving

Noise reduction

Fuel saving (smaller than ordinary fuel tank)

It is movable and can stop the machine anytime by the emergency button.

Lazersafe laser safety protection device comprehensively protects the personal safety of bending machine operators and avoids danger due to the rapid movement of the slider on the machine.

Hot Searches