A pipe per bending all individually preparing five action sequence and 10 sections of speed, allows the operator to match the use, improve work efficiency, reduce the fitting interference

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu,China

-

Brand Name:

-

BLMA

-

Year:

-

2024

-

Power (kW):

-

5.5

-

Weight (KG):

-

2500

-

Dimension:

-

4500x1600x1700mm

Quick Details

-

Bending Radius (mm):

-

10 - 180

-

Max. Bending Angle (Deg):

-

190

-

Bending Precision (Deg):

-

0.1

-

Place of Origin:

-

Jiangsu,China

-

Brand Name:

-

BLMA

-

Year:

-

2024

-

Power (kW):

-

5.5

-

Weight (KG):

-

2500

-

Dimension:

-

4500x1600x1700mm

Recommend Products

Products Description

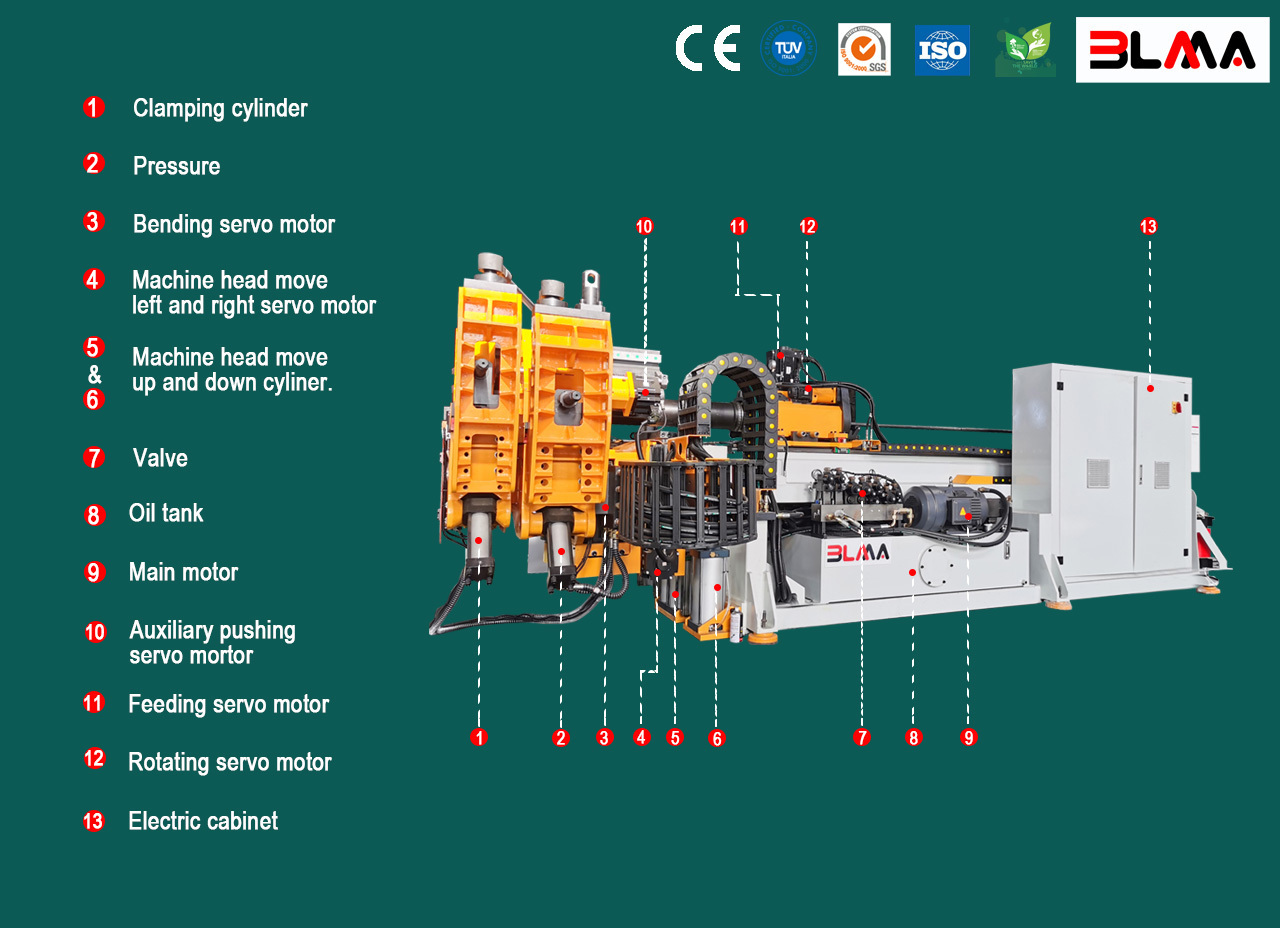

Main features

* Fully automatic and CNC pipe bending machine

* Equipped with 2 servo motor programmable axis

* Feeding: servo motor drive; Rotation: servo motor drive

* Bending: hydraulic and encoder control; Servomotor with reducer.

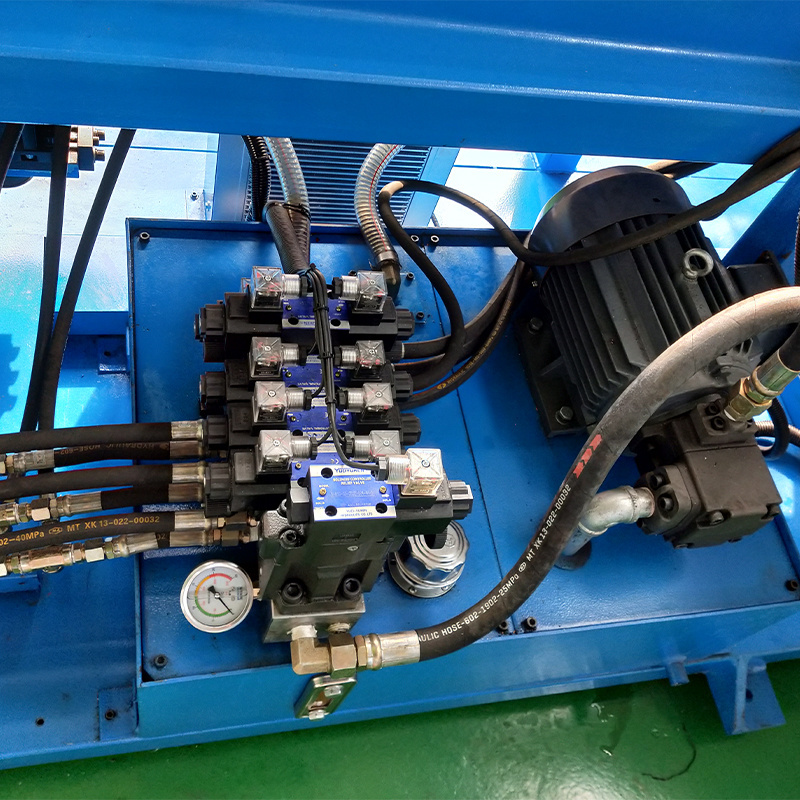

* Imported hydraulic system and PLC(standard) unit or IPC(optional).

* Automatic lubrication system for moving areas.

* Self-diagnostic system, detecting the error immediately.

* Multiple groups pipe-bending information storage.

* Electric cabinet cooling fan and the hydraulic cooling system ensure the equipment long-time work stably under the high temperature.

* Touch screen and human/machine interface control provide user friendly operations.

|

Max bending capacity

|

Ø50mmx2mm

|

|

Max bending radius

|

R250mm

|

|

Min bending radius

|

According to pipe diameter

|

|

Max bending degree

|

190°

|

|

Max effective distance of mandrel

|

3700mm

|

|

Feeding method

|

Direct feeding/clamping feeding

|

|

Bending speed

|

Max90°/s

|

|

Rotary speed

|

Max 160°/s

|

|

Feeding speed

|

Max1200mm/s

|

|

Bending accuracy

|

±0.1°

|

|

Rotary accuracy

|

±0.1°

|

|

Feeding accuracy

|

±0.1mm

|

|

Information inputting method

|

Working value (Y, B, C)

|

|

Bending method

|

Servo bending

|

|

Hydrualic motor power

|

5.5kw

|

|

Rotary servo motor power

|

750w

|

|

Feeding servo motor power

|

1.0kw

|

|

Max storage unit (3)

|

1000 groups

|

|

Max oil pressure

|

14Mpa

|

|

Machine weight

|

2500kg

|

PLC Controller

Bending sample

Hot Searches