- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1500 KG

-

name:

-

raymond mill

-

Application:

-

Stone Powder Grinding

-

energy consumption:

-

low

-

structure:

-

simple and firm

-

raw material:

-

good steel

-

colour:

-

as request

-

power:

-

suitable

-

warranty:

-

quality certificate

-

guarantee period:

-

one year

-

installation:

-

under the engineer's guidance

Quick Details

-

Capacity(t/h):

-

refer to the specifications

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HK

-

Weight:

-

1500 KG

-

name:

-

raymond mill

-

Application:

-

Stone Powder Grinding

-

energy consumption:

-

low

-

structure:

-

simple and firm

-

raw material:

-

good steel

-

colour:

-

as request

-

power:

-

suitable

-

warranty:

-

quality certificate

-

guarantee period:

-

one year

-

installation:

-

under the engineer's guidance

Widely Used and Low Consumption Raymond Pendulum Mill

ONE: Brief Introduction of Raymond Pendulum Mill :

1. For low consumption, low investment, environment friendly, small occupation area, and more efficient than the traditional mill, the Raymond Pendulum Mill is widely used in the field of metallurgy, building material, chemical industry and mining to process powder.

2. The Raymond Pendulum Mill is used in grinding the non-flammable and non-explosive stuff which has the Moh's hardness below 7, humidity less than 6%, such as gypsum, talc, calcite, limestone, marble, feldspar, barite, dolomite, granite, kaolin, bentonite, bauxite, iron ore etc., the final products change from 613 micron to 44micron.

3. Through the function of separator and blower, raymond pendulum mill can meet different customers' demand.

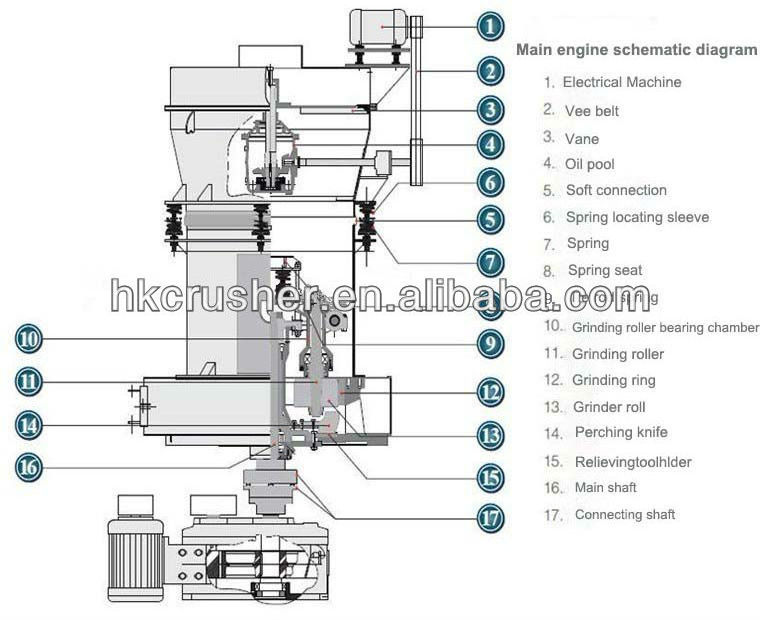

TWO: Structure of Raymond Pendulum Mill:

1, The whole plant is a vertical structure of strong systematic characteristic, so it occupies small area. From crushing of raw material to grinding and packing is an independent production system.

2, Driving system of main frame adopts airtight gearing and pulley, drives smoothly and operates reliably.

3, Main parts of the whole plant are made from high quality material. The technics is so subtly that insures the durability of whole plant.

4, The power control system makes the machine operate safely and automatically.

THREE: Working Principle of Raymond Pendulum Mill :

Firstly, raw material is crushed by jaw crusher to the size required, and then the crushed materials are elevated into a hopper from which the material is transported through the electro-magnetic vibrating feeder, evenly and continuously into the grinding chamber for powder-processing. The rollers oscillate outward to press the ring because of the centrifugal force and the shovel scoops up the materials, send to the middle between ring and roller to accomplish the grind.

After this, the ground stuff is carried by the air from the blower into the separator for screening. The fine powers are blow into the cyclone collector and are poured out through the output-powder valve as the final products and the rough stuff after the screening will be recycled back into the grinding chamber for regrinding. The set’s airflow system is closely sealed up and circulated under condition of negative and positive pressure.

FOUR: Main Technical Parameter of Raymond Pendulum Mill :

|

Model |

3R2115 |

3R2615 |

3R2715 |

3R3016 |

4R3216 |

||

|

Roller |

Number |

3 |

3 |

3 |

3 |

4 |

|

|

Diameter (mm) |

210 |

260 |

270 |

300 |

320 |

||

|

Height (mm) |

150 |

150 |

150 |

160 |

160 |

||

|

Ring |

Inside diameter (mm) |

630 |

780 |

830 |

880 |

970 |

|

|

Height (mm) |

150 |

150 |

150 |

160 |

160 |

||

|

Maximum feed size (mm) |

15 |

15-20 |

15-20 |

15-20 |

20-25 |

||

|

Output size (mm) |

0.044-0.165 |

0.044-0.165 |

0.044-0.165 |

0.044-0.165 |

0.044-0.165 |

||

|

Power of main frame (kW) |

15 |

18.5 |

22 |

30 |

37 |

||

|

Fineness of final product (mm) |

0.165 |

capacity (t/h) |

1.2-1.8 |

1.8-2.5 |

2.3-2.8 |

2.6-3.2 |

3.2-4.5 |

|

0.075 |

0.6-1.2 |

1.2-1.8 |

1.8-2.3 |

1.9-2.6 |

2.4-3.1 |

||

|

0.044 |

0.6-1.0 |

0.8-1.2 |

0.9-1.7 |

1-1.9 |

1.8-2.5 |

||

FIVE: Warranty of Raymond Pendulum Mill :

1. One Year (Calculated from the goods arrived the destination port.) If any parts (excluding easily damaging parts) are found defective in quality in the first year, we shall replace it free-of-cost. After one year, parts can be replaced on favorable payment basis. We can send our engineer to provide the installation and trial run in your place. But the relevant cost shall be bear in your account (round trip air ticket, board and lodging).

2. Our professional service includes: Free training, Guidance Installation and Debugging.

3. If you have any question, please contact us freely. Our after-sales service team on-line will do the best to accomplish your sincere requirement on time.

SIX: Maintenance and Repair of Raymond Pendulum Mill:

1. Prior to installation of the equipment, all the people who will be assigned to operate the equipment have to be technically trained to know the principle and rules of operation. Someone should be specially selected and put in charge of the operation.

2. To ensure normal operation of the equipment, a manual containing strict rules and procedures for its operation, maintenance and repair should be well prepared and followed. Tools, replacement parts for maintaining, repairing and lubricating oil and grease must be available for immediate use.

3. After a period of usage, the equipment should be checked, to replace worn-and-torn parts such as rollers, rings and shovels. Be sure to fasten connecting-bolts, nut collars to fix rollers properly. Be sure to lubricate the parts sufficiently.

4. Roller should be replaced after 500-hours use. To check and wash bearings, replace broken ones, then fill enough oil and grease (with oil-pump or grease-gun).