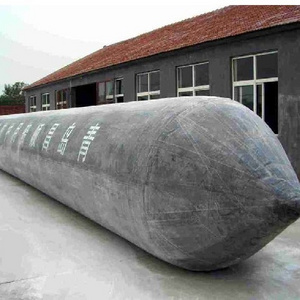

- Product Details

- {{item.text}}

Quick Details

-

BLACK:

-

RUBBER

-

WATER PROOF:

-

resistance to abrasion

-

3~18 Meter:

-

resistance to corrosion

-

vulcanizing:

-

vulcanization

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HAOHANG

-

Material:

-

HDPE

-

BLACK:

-

RUBBER

-

WATER PROOF:

-

resistance to abrasion

-

3~18 Meter:

-

resistance to corrosion

-

vulcanizing:

-

vulcanization

Company Brief Instruction:

| Qingdao Haohang Fender Airbag Co., Ltd. is located at 1760# Yanqing Rd, Jimo District, Qingdao, Shandong Province. | |||||

| We are specialized in Ship Launching Airbags, Marine Rubber Fenders, | |||||

| Pneumatic Floating Fenders, Boat Fender, Gas Airbag, Pipeline Airbag Etc. | |||||

| All of our products have approved by CCS, BV, ABS, SGS Etc. | |||||

| We have our own factory to process the Nature Rubber with machine Plasticating, | |||||

| Mixing and Compounding | |||||

| Adhering to the customer-oriented choice, the company provides customers with customized products, | |||||

| which are exported to Europe, North America and Asia, with rich production Experience, | |||||

| high quality standard requirements, to meet the needs of customers, timely and rapid after-sales maintenance, | |||||

| welcome you to visit the factory, discuss cooperation! | |||||

| Thanks for your notice! | |||||

Attn.Pls We are supplier of Raw Rubber Mat for making Airbags. :

Advantage:

It overcomes the shortcomings of the fixed launching track, which limits the productive capability of the small and medium sized shipyards.

Using the ship launch airbag becomes a flexible launching technology. The airbag has the advantage by saving time and labor.

It has the characters of flexibility, reliability and safety in ship launch operation. It is also economic.

Specifications:

| Model | Specification(D×L) | Application |

| 3-layer | Diameter(D): | For Small and medium-sized ship up to or down to launching way and moving objects |

| 0.8m, 1.0m, 1.2m, 1.5m, 1.8m,2m etc. | ||

| 4-layer | Length(L): | For the larger ship up to or down to launching way and moving objects |

| 5-layer | ranging from 5m to 18m | For large and medium-sized ship up to or down to launching way and moving objects |

| 6-layer or more | (Diameter and length can customize by the requirements of customers) | For large ship up to or down to launching way and supporting the key parts during operation |

Applications:

Our team developed the high strength shipping launching and landing airbags. We made a lot of ship launch airbag launcher burst test and compression performance test. All the data is over the relevant international and our country standards, and also exceeds the shipping line standard.

Besides the shipping launching and landing purpose, our rubber airbags also used for lifting and moving the heavy items, shipping salvage etc.

Dimension Tolerance and Appearance:

The length and the diameter of the ship launch airbag should be measured by the rated working pressure, the allowed tolerance is ±3%. The outer appearance of the shipping launching airbag should be smooth, bright without the crack, bubble, separated layers, pit or point.

Our company’s new integrated marine launching airbag adopts special rubber formula. And each rubber and fabric layer integrated with each other. The launch balloon head uses two layers more than the airbag body. This improves the work pressure of the airbag and enhances the strength of the marine airbag. Our airbags has good tightness, safety, and the longer life cycle. The use life is twice longer than the airbags in the market by our special rubber formulations.

Tests for Ship Launch Airbag:

1. Air tightness test

Fill the air into the pneumatic lifting bags to a certain internal test pressure without any load. After one hour, measure the internal pressure again. By comparing with two times’ data, the pressure loss should be less than 5%.

2. Performance test

Without any load, fill the air into the airbag balloon by the airbag standard data form or by clients’ requirement.

We will do the strictly inspection before the delivery for the outer appearance and the air loose test. If it is unqualified, can not release definitely.

3. Blasting test

This test should give the minimum burst pressure value of the airbag, as listed in the airbag performance table burst pressure. In order to be safe, since the airbag belongs to the pressure vessel, it is necessary to use a water flushing while filling the airbag until the airbag bursts. The water pressure during airbag blasting should be larger than or equal to the values listed in the standard performance table.

4. Compression-recovery Test

In order to verify the recoverability of the airbag, the airbag should be repeatedly and rapidly compressed and released in a short time. Due to the limitation of the airbag length and the limitation of the compression recovery equipment, the compression recovery test can be reduced by the same number of layers. The airbag is inflated to make the internal pressure reach the pressure of the airbag performance data. And the airbag is vertically compressed until the compression deformation reaches 75%. Keep this state for 1 minute. The pressure is then released and the balloon diameter should be restored to more than 97% of its original diameter within 5 minutes.

vulcanization:

Packing Method:

| Storage of the ship launching airbag | ||||

| 1. When we don’t use the marine airbag roller for a long time, it should be washed and dried. Should sue the external talcum powder on the lifting airbag surface. Should put the airbag in a dry, ventilated room away from the light source. Keep away the shipping airbags safe to avoid stretching, compression and deformation. | ||||

| 2. Keep the airbag away from heat sources. | ||||

| 3. Can not contact the airbags launching to acids, alkalis, greases and organic solvents. | ||||

| 4. When the airbag ship is not in use, we should keep it in the status of stretched flat, not stacked, and no heavy objects piled on it. | ||||

| Notice during the use of the ship balloon: | ||||

| 1. While the shipping air launching airbags are in use, strictly control the pressure, prohibit use of exceeding the work pressure. | ||||

| 2. The surface in contact with the shipping lifting airbag must not have a sharp protruding hard object to prevent the airbag skin from being pierced. | ||||

| 3. Try to avoid distortion in the length of the airbag. | ||||

| 4. Should avoid the inflatable load after we have in charged the air into the airbag. | ||||

| For example, when the ship is erected, when the lifting airbag has lifted most of the hull, remove most of the pier and fill the rolling airbag. If there are 1-2 piers still under compression, the internal pressure between the airbags should be adjusted so that the ship can be removed from the side of the ship. And the pier can not be manually used. Otherwise, the ship may be forced to impact the airbag that has been filled. | ||||

| Another example is the collision with other objects for various reasons during the ship transfer process. In severe cases, the impact airbag may be damaged. | ||||

| 5. Before long time no use or re-use after repair, we should carry out the air filling test again. The air internal pressure should be the same as the factory test value of our factory. The test worker should keep away three meters from the airbag during the test. If the airbag repaired by a large area damage, we should decrease the use pressure. Therefore, for the airbag often used, still need the above test once a year. | ||||

| 6. Do not drag the ship launch airbag on the hard ground. | ||||

Tech of Our Airbags:

Our company invented the new overall winding technology . The new technology ensures the good quality of our marine airbags, which makes our marine airbags to be more durable and safer.

Exhibition:

FAQ:

1."I have ships but don't know how to choose the size of Marine Airbag."

Answer: Don't worry .We have more than 10 years' experience. Pls tell me information of your ship, we can suggest suitable size for you.

2."I want to try your

Marine Airbag

, but I never use it and don't know how to use, can you help me?"

Answer: Don't worry. We will send instruction book together with

Marine Airbag

.

3."What's your MOQ?"

Answer: Our MOQ is 1PC.

4."How about the lifespan of your

Marine Airbag

?"

Answer: Designed lifespan of our

Marine Airbag

is 6 to 10 years

5."What's your warranty period ?"

Answer: Our warranty period is 2 years. we will responsible for the repairment or replace the new ones for you if it proved to be our quality problem.

6."What kind of certificate can you provide ?"

Answer: CCS, SGS etc. certificate is available.