- Product Details

- {{item.text}}

Quick Details

-

Thermal Conductivity:

-

0.165

-

Thickness:

-

6/10/15/20/25/30/40/50 Mm

-

Width:

-

400/600mm

-

Length:

-

600-1220mm

-

Working Temperature:

-

1100C/1260C/1360C/1430C

-

Shrinkage (1800℉, 3h):

-

3 (24hours)

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Standard

-

Brand Name:

-

RongSheng

-

Color:

-

White

-

Classification Temperature(℃):

-

1260

-

keyword:

-

ceramic fiber board

Quick Details

-

Chemical Composition:

-

AL2O3+SIO2+ZrO2

-

Ultimate Strength (≥ MPa):

-

0.5MPa

-

Fiber Diameter:

-

3-5

-

Thermal Conductivity:

-

0.165

-

Thickness:

-

6/10/15/20/25/30/40/50 Mm

-

Width:

-

400/600mm

-

Length:

-

600-1220mm

-

Working Temperature:

-

1100C/1260C/1360C/1430C

-

Shrinkage (1800℉, 3h):

-

3 (24hours)

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Standard

-

Brand Name:

-

RongSheng

-

Color:

-

White

-

Classification Temperature(℃):

-

1260

-

keyword:

-

ceramic fiber board

Special size and OEM Service also provide!

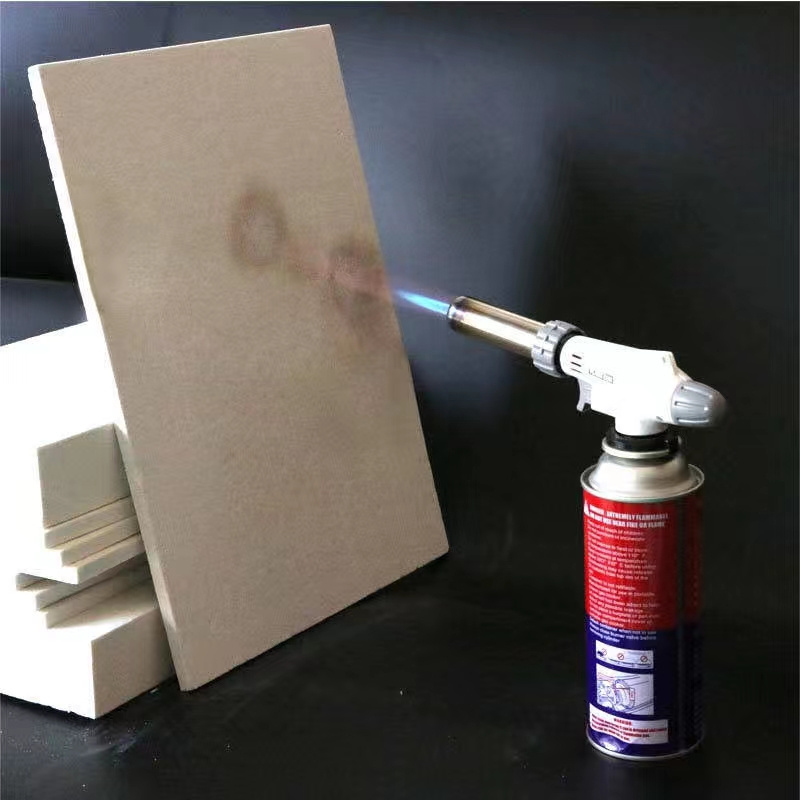

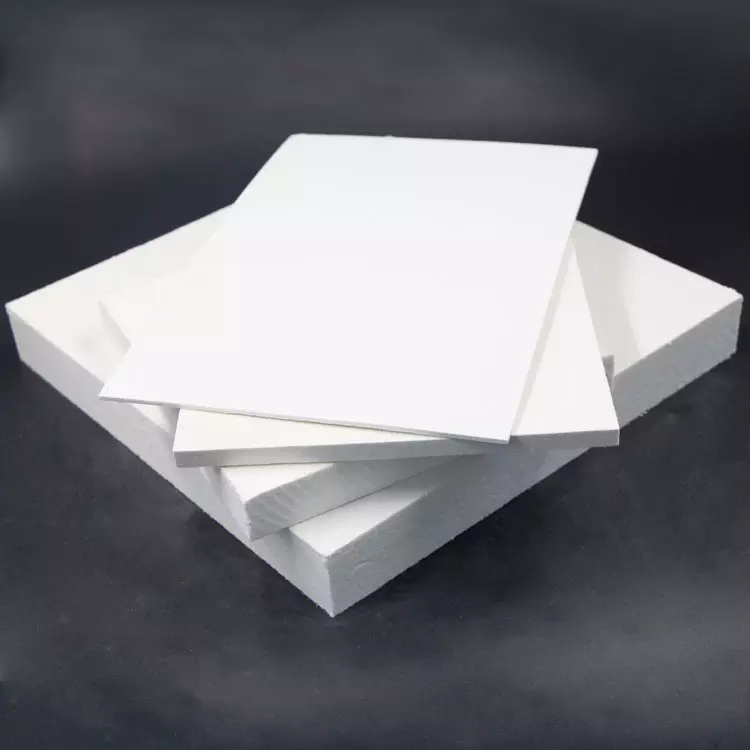

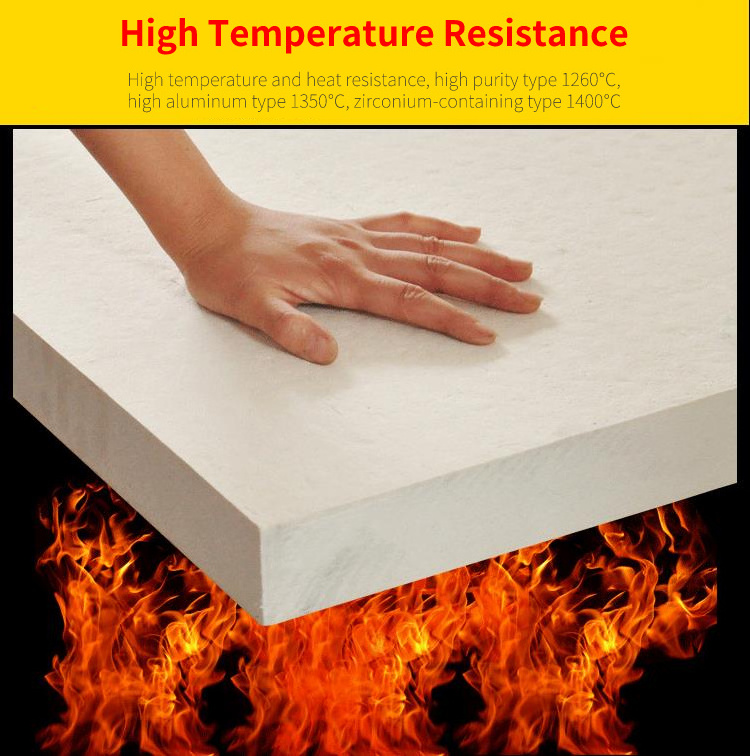

Ceramic fiber board is a high-performance insulating product formed by ceramic fiber and adhesive in vacuum. It is flat, ceramic materials are evenly distributed, and has excellent heat insulation performance. Due to its low thermal conductivity and low heat storage, no inflation during heating can reduce energy cost and cycle time, and protect the refractory surface from thermal shock and chemical attack. Therefore, it is an ideal product for fire resistance, heat insulation and heat insulation.

Ceramic fiber Board Advantage :

♦ Needled blanket

♦ Non-combustible

♦ Low density and low thermal conductivity

♦ Shorter heat up and cool down time

♦ Resilience and resistance to thermal shock

♦ Flexible and easy to cut or install

♦ Consist of acoustic properties

♦ Contain no organic binder

♦ Asbestos free

Ceramic fiber Board Specification

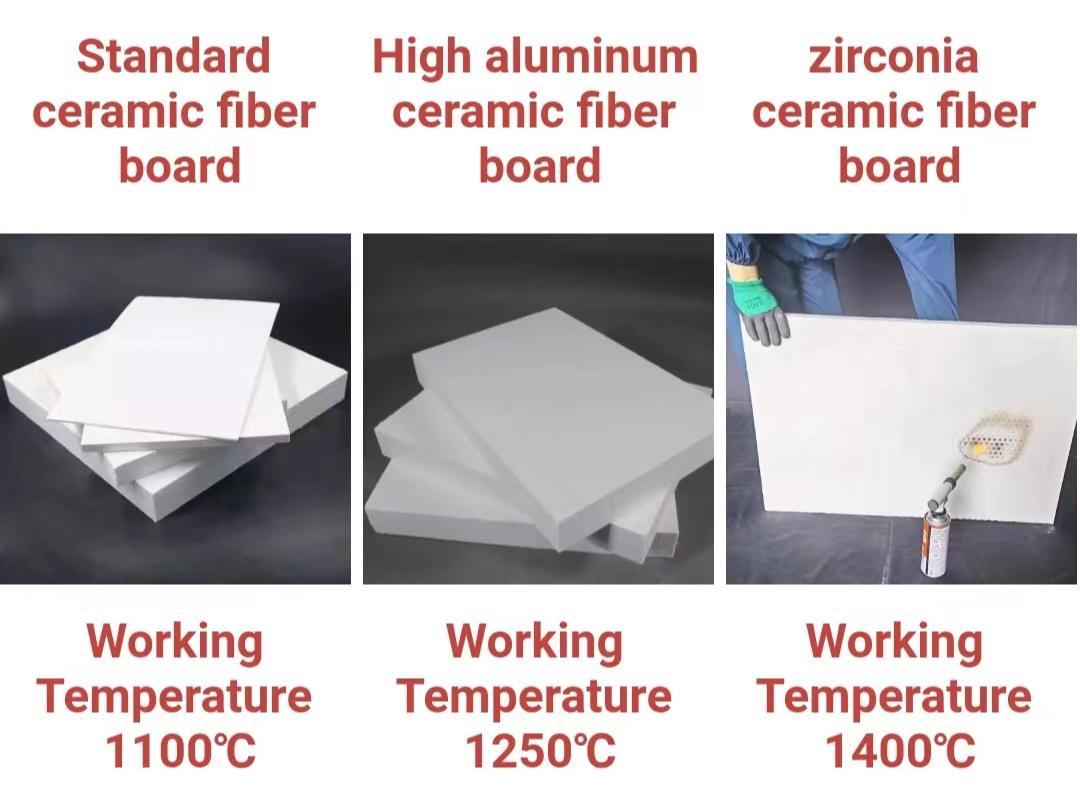

Standard ceramic fiber blanket - working temperature 1050 ℃

High-alumina ceramic fiber blanket - working temperature 1260 ℃

Zirconia ceramic fiber blanket - working temperature 1350 ℃

Thickness 6-50mm

| Type | common | standard | high pure | high aluminum | zircon | |

|

classfication Temperature(℃)

|

1100 | 1260 | 1260 | 1360 | 1430 | |

| Working Temperature(℃) |

≤1000 |

1050 | 1100 | 1260 | 1350 | |

| color | white | pure white | pure white | pure white | pure white | |

|

Shrinkage on heating (%)(Temperature 24 hours, density as 320kg/m3) |

-4 (1000°C) |

-3 (1000°C) |

-3 (1100°C) |

-3 (1200°C) |

-3 (1350°C) |

|

|

Thermal conductivity of various temperatures (w/m.k) (density 285kg/m3) |

0.085 (400°C) 0.132 (800°C) 0.180 (1000°C) |

0.085 (400°C) 0.132 (800°C) 0.180 (1000°C) |

0.085 (400°C) 0.132 (800°C) 0.180 (1000°C) |

0.085 (400°C) 0.132 (800°C) 0.180 (1000°C) |

0.085 (400°C) 0.132 (800°C) 0.180 (1000°C) |

|

|

Compressive strength (Mpa) |

0.5 | 0.5 |

0.5 |

0.5 | 0.5 | |

|

Chemical composition (%) |

AL 2 O 3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

|

AL

2

O

3

+SIO2 |

96 | 97 | 99 | 99 | - | |

|

AL

2

O

3

+SIO2+ZrO2 |

-

|

- |

-

|

- | 99 | |

|

ZrO2 |

- | - | - | - | 15-17 | |

|

Fe2O3 |

<1.2 |

<1.0 |

0.2 | 0.2 | 0.2 | |

|

Na2O+K2O |

<0.5 |

<0.5 |

0.2 | 0.2 | 0.2 | |

|

Dimensions (mm) |

Common Specifications: 600*400*10-50; 900*600*10-50 1200*500*10-50; 1200*1000*10-50; 1000*600*10-50 Other specifications can be available. |

|||||

Our product Advantage:

Competitive Price. Make the products competitive in your market.

Abundant Experience. Prevent cracks and twist in bricks.

Different Moulds. Save mould fees for you.

Strict Quality Control. Meet clients’ quality requirement.

Large stocks. Guarantee prompt delivery.

Professional Packing. Avoid damage and secure the goods in transportation

Fire resistant ceramic fiber Board Applications:

Heat resistant fiber board plays important role in high temperature equipment, and is extensively

applied in various industries:

Iron and steel industry: Expansion joints;

In non-ferrous industry: Tundish, the launder lid;

Light industry: Furnace lining of the industrial or household boiler;

Ceramic industry: Light kiln car, hot face of the furnace body, and being used as the fire-barrier material;

Glass industry: Insulation layer of the smelting furnace, and glass molten pool, etc.

Zhengzhou Rongsheng Refractory Material Co., Ltd.

Established in the early 90s of twenty century, with continuous innovation and development, now we are a comprehensive enterprise in refractory material industry, covering metallurgy, building materials, electric power, chemical industry,etc.

Our main products: refractory material for industrial furnaces, such as high-alumina brick, clay brick, silicon brick, high-strength diatomite brick, light weight insulation brick, low iron mullite brick, etc.; anti-stripping alumina brick, alkali proof brick, phosphate brick for cement industry; For the industrial furnace and power boiler, we can provide abrasive brick, corundum brick, mullite brick, wear resistant castable, corundum castable, high strength low cement castable, impervious material, plastic refractory, graphite electrode etc.

Our main export markets : North America, Western Europe, Eastern Europe, South America, Southeast Asia, Eastern Asia, Mid East, Oceania, Africa

We have own workshop , advanced production line , experienced workman and stricted check out flow .

We always pursue the objective of "Honesty, Courtesy, Innovation, Dedication", the cornerstone of "Super Quality & Competitive Price", and the strategic goal of building Rongsheng brand, to serve the clients in a timely and effective way.

Rongsheng Refractory has professional sales and after-sale service team who provide customers all-around service about product application, construction installation and operation technology training etc. Now we have established cooperation relationship with many science and research unit and our products have been sold to Japan, Indonesia, Iran, Kazakhstan and Vietnam etc.

Q1: Is your Zhengzhou Rongsheng Refractory a manufacturer or trader?

A1: Manufacturer, some time we help our clients to purchase relevant products as a trader.

Q2: What’s the MOQ?

A2. No limitation.

Q3: Can we visit your factory?

A3: Of course ,welcome at any time,seeing is believing

Q4: What’s your payment terms?

A4: Negotiation

Q5: Is your company accept customization?

A5: Professional technology teams and engineers all can satisfy you.

Q6: How do you guarantee quality?

A6: For every production processing,we have complete QC system for the chemical composition and Physical properties.After production,all the goods will be tested ,and the quality certificate will be shipped along with goods.

Q7: What’s the proportion of abroad business?

A7: Abroad market around 35%; Domestic market around 65%; and now export proportion is increasing.

Q8: Does your Zhengzhou Rongsheng Refractory provide turn-key projects?

A8: Yes, we already finished several turn-key projects at home and abroad.

Q9: Does your Zhengzhou Ronghseng Refractory supply samples?

A9: Yes, we can supply samples for free, and the freight will be undertaken by clients.