- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5540*2300*1850

-

Weight:

-

10020 KG

-

Name:

-

Alumina Ball Mill

-

Max. Feeding size:

-

25mm

-

Output size:

-

2-0.074mm

-

Max. balls loading:

-

4tons

-

Liner Materials:

-

Manganese Steel, Alumina, Rubber

-

Color:

-

Blue or as your request

-

Function:

-

Stone grinding

-

Processed Materials:

-

Minerals

-

Installation:

-

Engineer Guide

-

Certificate:

-

CE

Quick Details

-

Capacity(t/h):

-

1.6-4.1

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Hengchang

-

Dimension(L*W*H):

-

5540*2300*1850

-

Weight:

-

10020 KG

-

Name:

-

Alumina Ball Mill

-

Max. Feeding size:

-

25mm

-

Output size:

-

2-0.074mm

-

Max. balls loading:

-

4tons

-

Liner Materials:

-

Manganese Steel, Alumina, Rubber

-

Color:

-

Blue or as your request

-

Function:

-

Stone grinding

-

Processed Materials:

-

Minerals

-

Installation:

-

Engineer Guide

-

Certificate:

-

CE

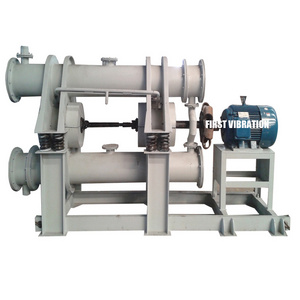

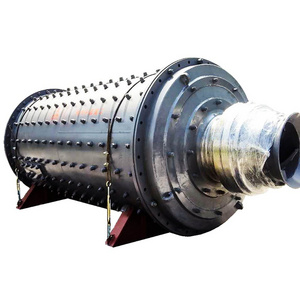

Long Working Life Wet And Dry Type Quartz Silica Sand Grinding Machine Slag Grinder High Alumina Ball Mill With Ceramic Liner

Hengchang machinery ball mill can be used for many minerals grinding, such as stone, rock, gold, copper, iron and zinc ore and so on

. In the industry of mining,

it is used to grind kinds of materials into fine powder 20-75 micrometer. Based on discharging type, it could be grate type, overflow type, etc.

Products Description

Ball mill is a type of grinder used to grind materials into an extremely fine powder mainly for use in the mineral processing industry. Ball mills can grind various ores and other materials either wet or dry, depending on requirements.

Hengchang ball mill is a key equipment to grind the crushed materials, which is

widely used in the mining process, and it has a wide range of usage in grinding mineral or material into fine powder, such as

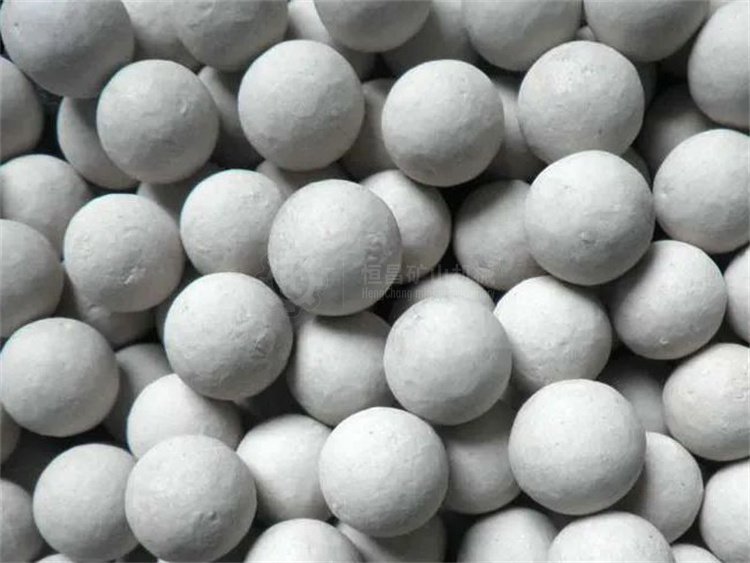

gold, iron, zinc ore, copper, cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics. Dry type ball grinding mill is to grind feldspar, glass, dolomite, quartz, silica sand etc. Using ceramic lining plate, the raw material could keep high purity.

gold, iron, zinc ore, copper, cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics. Dry type ball grinding mill is to grind feldspar, glass, dolomite, quartz, silica sand etc. Using ceramic lining plate, the raw material could keep high purity.

Product Working Principle

Ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

The grinding media is the balls, which may be made of steel (chrome steel), ceramic. The inner surface of the cylindrical shell is usually lined with an abrasion-resistant material such as manganese steel

, ceramic

or rubber.

Product Features

1. High beneficiation efficiency, high fineness of ore powder.

2. Large discharge port, large handling capacity.

3. High production capacity, smooth operation.

4. Easy to install and maintain.

Product Paramenters

|

Model

|

Revolution

(r/min)

|

Balls

(t)

|

Max size

(mm)

|

Capacity

(t/h)

|

Power

(kw)

|

Dimension

(LxWxH)mm

|

Weight

(kg)

|

|

GM0912

|

41.6

|

1.1

|

25

|

0.3-0.9

|

11

|

3843*1850*1400

|

4210

|

|

GM0918

|

41.6

|

1.5

|

25

|

0.4-1.2

|

11

|

4443*1850*1400

|

5800

|

|

GM0921

|

41.6

|

1.8

|

25

|

0.6-1.5

|

15

|

4743*1850*1400

|

6660

|

|

GM0933

|

41.6

|

2.8

|

25

|

0.9-2.3

|

30

|

5943*1850*1400

|

7770

|

|

GM1224

|

35.1

|

4.0

|

25

|

1.6-4.1

|

37

|

5540*2300*1850

|

10020

|

|

GM1232

|

35.1

|

5.3

|

25

|

2.2-5.5

|

45

|

6340*2300*1850

|

11230

|

|

GM1244

|

35.1

|

7.3

|

25

|

3.0-7.5

|

55

|

7540*2300*1850

|

13210

|

|

GM1324

|

30.2

|

4.5

|

25

|

1.5-3.5

|

37

|

5035*2370*1880

|

10210

|

|

GM1334

|

30.2

|

6.5

|

25

|

2.2-5.0

|

75

|

6035*2370*1880

|

13117

|

|

GM1524

|

30.7

|

7.0

|

25

|

2.8-6.5

|

55

|

6830*2930*2060

|

15430

|

|

GM1530

|

30.7

|

9.0

|

25

|

3.5-8.0

|

80

|

7430*2930*2060

|

16843

|

|

GM1536

|

30.7

|

11.0

|

25

|

4.5-10.0

|

95

|

8030*2930*2060

|

18649

|

|

GM1545

|

30.7

|

13.5

|

25

|

5.5-13.5

|

110

|

8930*2930*2060

|

20000

|

|

GM1830

|

25.04

|

13.0

|

25

|

3.0-17.0

|

130

|

9525*3960*2250

|

29490

|

|

GM1836

|

25.04

|

15.0

|

25

|

4.0-21.5

|

155

|

10125*3960*2250

|

31600

|

|

GM1844

|

25.04

|

19.0

|

25

|

5.2-26.0

|

180

|

10925*3960*2250

|

34210

|

|

GM1864

|

25.04

|

27.0

|

25

|

8.0-40.0

|

210

|

12925*3960*2250

|

42440

|

|

GM2130

|

23.8

|

20.0

|

25

|

4.0-30.0

|

180

|

8475*4060*3400

|

41965

|

|

GM2145

|

23.8

|

25.0

|

25

|

5.6-42.0

|

280

|

9975*4060*3400

|

49230

|

|

GM3245

|

18.7

|

65.0

|

25

|

100-145

|

630

|

13000*7200*5700

|

145000

|

Successful Case

2100*4500 Ball Mill in South Africa

For grinding chrome ore.

1830*3000 Overflow Ball Mill in Tanzania

For grinding gold ore.

2100*3000 Ball Mill in China

For

grinding copper

ore

.

1830*4500 Ball Mill in China

For

grinding

lithium ore

.

1200*3000 Ball Mill in Zambia

For grinding rock gold ore.

1500*4500 Wet Ball Mill in Mali

For gold processing plant.

1530 and 1224 Sag Ball Mill in Myanmar

For gridning

tungsten ore

.

1500*3000 Dry Rubber Ball Mill in Thailand

For gridning

aluminium powder

.

Hot Searches