- Product Details

- {{item.text}}

Quick Details

-

Medium:

-

liquid asphalt, hot asphalt, etc

-

Overall dimension:

-

10200*2500*3730mm

-

Asphalt tank volume:

-

8 cbm

-

Asphalt pump:

-

QGB950, 950 liters/min

-

Burner:

-

ITALY import G20

-

Wheelbase:

-

4600+1350mm

-

Engine power:

-

WD615.95 336PS Euro 3 diesel engine

-

Axle & tire:

-

3 axles, 10 wheels, 11.00R20 tires, with a spare tire

Quick Details

-

Place of Origin:

-

Hubei, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Drive cabin:

-

3 seats, with a sleeper, RHD steering wheel

-

Medium:

-

liquid asphalt, hot asphalt, etc

-

Overall dimension:

-

10200*2500*3730mm

-

Asphalt tank volume:

-

8 cbm

-

Asphalt pump:

-

QGB950, 950 liters/min

-

Burner:

-

ITALY import G20

-

Wheelbase:

-

4600+1350mm

-

Engine power:

-

WD615.95 336PS Euro 3 diesel engine

-

Axle & tire:

-

3 axles, 10 wheels, 11.00R20 tires, with a spare tire

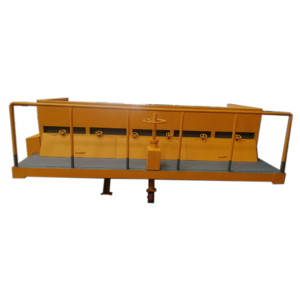

CLW Synchronous Chip Sealer Spreader

- Sinotruck HOWO 6x4 336HP diesel engine, RHD steering wheel, 10-speed gearbox, air brake, 12.00-20 tires, 80km/h

- CLW high end professional bitumen and gravel spraying & controlling system, import components, burner, control, pump, nozzles, etc

- Stainless steel outer surface, insulation tank

- 0.8~3L/cbm spraying capacity, 4.5~6m spraying width

- High end equipment for road construction

RHD Synchronous Chip Sealer Spreader Truck

| Product Name | Synchronous chip sealer spreader |

| Chassis & Year | SINOTRUK HOWO (RHD CAB), 2019 new |

| Volume of Asphalt Tank | 8cbm |

| Volume of Gravel Hopper | 12~14cbm |

| Overall Dimension | 10200*2500*3730mm |

| Tank material | Carbon steel + stainless steel |

| Thickness of Insulation Layer | 100mm insulation layer in middle of tank body |

| Gross Weight | 25000kg |

| Curb Weight | 17370kg |

| Payload | 7500kg |

| Wheelbase | 4600+1350mm |

| Fuel Type | Diesel |

| Engine | WD615.95, 336PS, 9.726L, 4 stoke, EGR, turbocharged intercooled,water cooling |

| Transmission | HW90710, manual, 10 front gears and 2 rear gear |

| Brake | Automatically air cut-off brake |

| Axle & Tire | 3 axle, 10* 11.00R20 Linglong brand tires |

| Max speed | 80km/h |

| Bitumen Spray System Options (Please select which type you need when inquiry) | |||

| Type | Common Type | Standard Type | Smart Type |

| Volume of Asphalt Tank | 6 | 8 | 8 |

| Volume of Gravel Hopper | 10 | 14 | 14 |

| Model of asphalt pump | QGB680(680L/min) | QGB950(950L/min) | TGGP-185-125(950L/min) |

| Origin of asphalt pump | China made | China made | China made |

| Medium | Hot/Dilute/ E mulsify asphalt | Hot/Dilute/ E mulsify asphalt | Hot/Dilute/ E mulsify asphalt |

| Hydraulic System | Shanxi YUCI | Shanxi YUCI | Shanxi YUCI |

| Proportional Valve | Taiwan EFBG-03-160-HF | Taiwan EFBG-03-160-HF | Taiwan EFBG-03-160-HF |

| Reversing Valve | √ | √ | √ |

| Relief Valve | √ | √ | √ |

| Model of Hydraulic Pump | 50-20-16 | 50-20-16 | German Rexroth |

| Model of Hydraulic Motor | 05-110-BD31 | 05-110-BD31 | 05-110-BD31 |

| Radiator | RISHENG brand | RISHENG brand | RISHENG brand |

| Control System | German Siemens CLW-3 2 -01 | German Siemens CLW-3 2 -01 | German Siemens CLW-32-01 |

| Control Type | Computer smart control, 1-control-1 | Computer smart control, 1-control-1 | Computer smart control, 1-control-1 |

| Operation Person Number | 1 persons | 1 persons | 1 persons |

| Asphalt Nozzle Number | 32 | 32 | 32 |

| Heating Type | Heat conducting oil automatically heating | ||

| Conducting Oil | Hebei,China | ||

| Burner | Italy import G10 | ||

| Power of Engine | 6KW | 6KW | HONDA 5.5KW |

| Spraying Capacity | 0.3~3.5L/min | 0. 3~3.5 L/min | 0.2~4L/min |

| Spraying Error | ±2% | ±2% | ±2% |

| Spraying Width | 4m | 4 m | 4m |

| Remark | If you need to sprinkle rubber asphalt, please call 0086 13872883675 | ||

* More details or special requirements about our synchronous chip sealer truck, please contact us by 0086 18372220016(whatsapp/phone).

Images of Synchronous Chip Sealer Spreader:

Synchronous chip sealer mainly includes: asphalt distribution system, stone spreading system, electrical operating system, auxiliary system components.

Asphalt sprinkling system: Sprinkler system mainly asphalt tank, heating part, hydraulic part, the control part and spray part.

Gravel Spreading System:

Stone sprinkling system has silos, material door control mechanism and spreader.

The silo is installed with the inner shadow Tibetan-style overhead turning shaft with through shaft to ensure the stability of the silo rise; material door is 16-way control, the angle of the helix angle controller, to make the material door to a certain opening, Can be set on the angle controller door opening angle, very convenient and accurate. Effectively adjust the spreading uniformity, changing the uneven distribution of the traditional stone situation; the distribution plate and the cutting board adjustment range, for different specifications (S3 ~ S24mm) of stone.

Electrical Operating System:

1, according to different needs of the operator to provide accurate sprinkling parameters.

After setting the display parameter of the stage, the continuous change of the actual measurement parameters can accurately reflect the operation of the equipment.

2, manual operation is simple, can achieve manual / automatic switching, improve work efficiency.

3, according to the width of the road to adjust spray asphalt, spreading the width of stone.

4, the use of limit switch device, the nozzle rack, silo lift control to avoid over-man-machine damage.

5, configuration automatic oil heat conduction device, with the upper limit, lower limit alarm, asphalt lower limit alarm indication.