- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Dewatering manure

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fusion

-

Type of manure process equipment:

-

Electric type

-

Capacity of manure process device:

-

15-20 m3/H

-

Screen diameter of manure process system:

-

200 mm

-

Drain diameter of manure process device:

-

110 mm

-

Dimension manure process device:

-

2200*610*1350 mm

-

Related new design machine:

-

Diagonal screen type dewatering machine

-

Use of the dung manure process device:

-

Dewater Animal Manure, pig poultry, cow dung

-

Name of the manure dewatering machine:

-

Cow Dung Manure Dewatering Machine/Cow Dung Dehydrator

-

Power manure process device:

-

4kw

-

Inlet diameter manure process device:

-

76mm

Quick Details

-

Weight (KG):

-

350

-

Marketing Type:

-

Hot Product 2023

-

Type:

-

Screw dewatering machie

-

Use:

-

Dewatering manure

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fusion

-

Type of manure process equipment:

-

Electric type

-

Capacity of manure process device:

-

15-20 m3/H

-

Screen diameter of manure process system:

-

200 mm

-

Drain diameter of manure process device:

-

110 mm

-

Dimension manure process device:

-

2200*610*1350 mm

-

Related new design machine:

-

Diagonal screen type dewatering machine

-

Use of the dung manure process device:

-

Dewater Animal Manure, pig poultry, cow dung

-

Name of the manure dewatering machine:

-

Cow Dung Manure Dewatering Machine/Cow Dung Dehydrator

-

Power manure process device:

-

4kw

-

Inlet diameter manure process device:

-

76mm

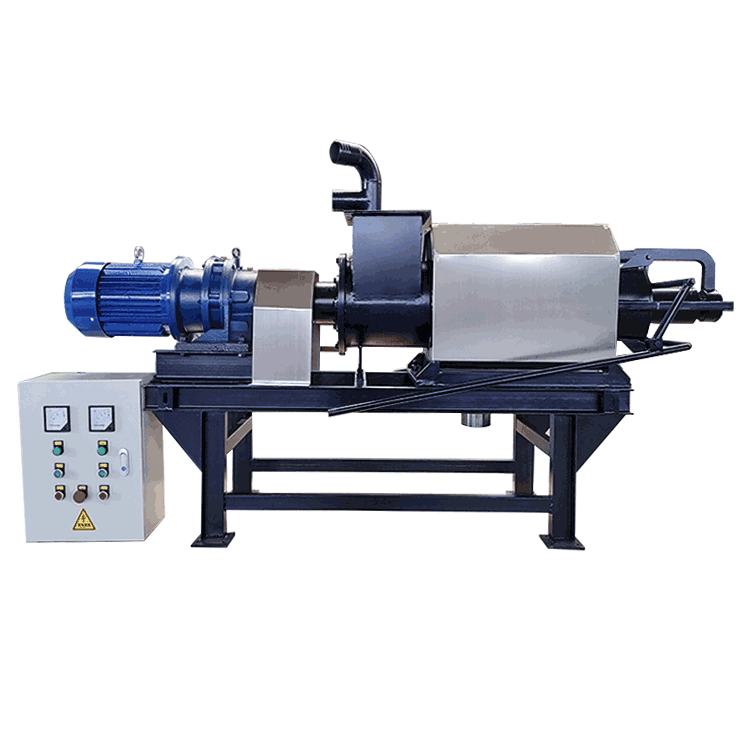

Animal waste chicken cow dung dewatering machine manure fertilizer solid liquid separator machine / 180 200 280 pig manure dewatering machine soild liquid separator Manure Separator Screw centrifuge slurry separator

Description about Cow Dung Manure Dewatering Machine

Screw press solid liquid separator is widely used in farm, especially for manure dewatering for cow, pig, horse, chicken, etc.

1. The screw solid-liquid separator dewatering machine has small volume, low speed, simple operation, convenient installation and maintenance, low cost, high efficiency, fast investment recovery;

And no need to add any flocculant.

The weight of the whole machine is nearly half a ton and the dimensions are small.

2. The separated solid part is dry and odorless. It is a good farmland fertilizer. It does not produce leachate during storage.

It is convenient to transport and store.

It can effectively improve the air environment of livestock farms and solve the problem of solid manure transportation Environmental Pollution.

After separation, the water content of the liquid portion is 60% or so, and crusts and precipitation are not easy to occur during storage.

The separated liquid has less nitrogen and phosphorus content, which can be diluted for irrigation water or fertilizer, and can be effectively used by agricultural crops absorb.

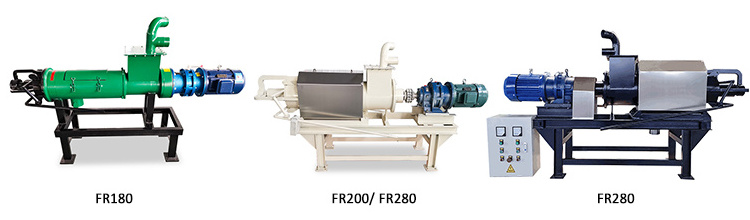

Models and Parameter of screw dewatering machine dewater/dung dewater machine

| Model | FR-180 | FR-200 | FR-280 |

| Voltage | 380V | 380V | 380V |

| Power | 4kw | 4kw | 5.5kw |

| Dimension | 2000*600*1300 | 2200*610*1350 | 2400*800*1300 |

| Weight | 340kg | 510kg | 680kg |

| Capacity | 10-15 M³/H | 15-20 M³/H | 20-25 M³/H |

| Sieve dia. | 180mm | 200mm | 280mm |

| Inlet dia. | 76mm | 76mm | 76mm |

| Material | Carbon steel+304SS | Ductile iron+304SS | Ductile iron+304SS |

01 discharge port Solid liquid separation of raw material,soil discharge port

02 Stainless stell screen Stainless steel screen,good quality and long service life.

03 Screw All welding technology is adopted.More durable and durable

04 Control cabinet Well known electrical appliances,overload protection,security

Solid 304 spiral shaft,corrosion resistance,oxidation resistance,accelerate discharge speed

Independent distribution box and Pure copper motor

The main components are: body, screen, extrusion auger, reduction motor, unloading device and other components.

When the cutting feed pump pumps the mixed liquid to the solid-liquid separator through the pipeline, the separator starts, the squeeze auger gradually pushes the mixed liquid to the front of the body, and at the same time, continuously increases the pressure at the leading edge, forcing the moisture in the material to squeeze out Mesh screen, flowing out of the drain pipe. The work of the extruder is continuous, and its materials are continuously pumped into the body, and the pressure at the leading edge is constantly increasing. When it reaches a certain level, the discharge opening is pushed open, and the extrusion opening is squeezed to achieve the extrusion discharge purpos.

Bulk shipping for manure dewatering machines:

The old customers feedback of screw dewatering machine real site and working effect

Related manure dewatering for clients to choose:

1. We always welcome customers to visit our manufacturing factory and get to know more about us.

2. Customers can see all the manufacturing workflows when they visit our factory. you can contact with online besides offline:

Tel/ Wechat/ WhatsAPP/ iMessages: +86 155 0374 7612

3. We also send engineers to the customer's place to help with the installation!

1. Packing: PP film wrapped around the machine and carefully packed in wooden case to focus on protecting damageable parts.

2. Shipping: From port of Shenzhen, Shanghai, Qingdao, Guangzhou,etc. We also accept land, air, sea transport and

internationalmultimodal transport.

3. Clearance: Our long history makes us the one of the first and most knowledgeable providers of the equipment, our main customers hail from; Canada, the United States, Brazil, Argentina, Japan, Philippines, Australia, Russia, Thailand,

Poland, Spain, Germany, India, etc.