- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

22.5

-

Range of Spindle Speed(r.p.m):

-

3200 - 5800 r.p.m

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Doing Machine

-

Voltage:

-

380V,50Hz,3P

-

Dimension(L*W*H):

-

850x1800x3100mm

-

Weight (KG):

-

850 KG

-

Model:

-

WFJ series

-

Capacity:

-

10-1200 Kg/h

-

Size of input:

-

less than 12mm

-

Size of output:

-

80-550 mesh

-

Total power:

-

13.5-85kw

-

Weight:

-

850-3200kg

-

construction material:

-

SUS304,SUS316

-

Dust collector:

-

cyclone and bag filer

Quick Details

-

Output (kg/h):

-

10 - 1200 kg/h

-

Feeding Size (mm):

-

5 - 15 mm

-

Output Size (mesh):

-

80 - 350 mesh

-

Power (kW):

-

22.5

-

Range of Spindle Speed(r.p.m):

-

3200 - 5800 r.p.m

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Doing Machine

-

Voltage:

-

380V,50Hz,3P

-

Dimension(L*W*H):

-

850x1800x3100mm

-

Weight (KG):

-

850 KG

-

Model:

-

WFJ series

-

Capacity:

-

10-1200 Kg/h

-

Size of input:

-

less than 12mm

-

Size of output:

-

80-550 mesh

-

Total power:

-

13.5-85kw

-

Weight:

-

850-3200kg

-

construction material:

-

SUS304,SUS316

-

Dust collector:

-

cyclone and bag filer

Product Description

Main features

1. Fine and ultra-fine grinding of soft to medium hard materials with a controlled particle size distribution;

2. Size of output product: 60-320 mesh

3. Capacity: 10-1500 kg/h

4. GMP design

5. Cyclone and bag filter are equipped.

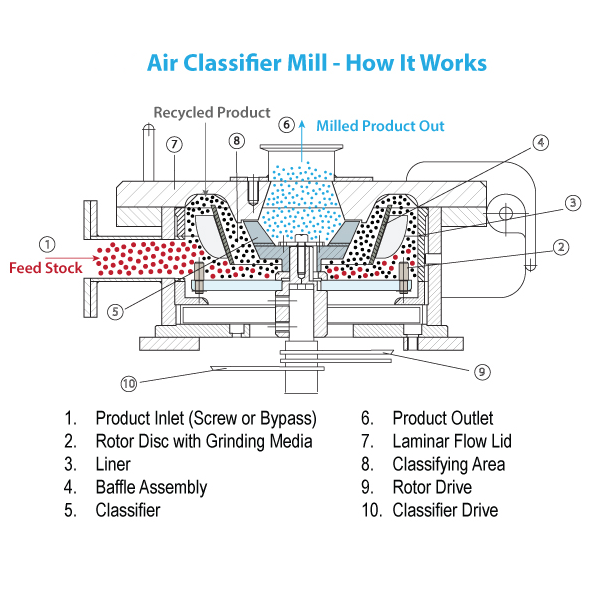

Working principle

WFJ series air classifying mill pulverizer are high-energy vertical grinding mills incorporating an internal air classifying wheel to controll product particle size distribution.

Material is fed into the grinding chamber via screw feeder and strongly impacted and collided into fine powder between the high-speed disc rotor and teeth liner. After grinding process, fine powders are carried to the classifying section by airflow where qualified powders are suctioned into the interior of the classifying wheel and discharged as products; coarse powders flow through the inner guide ring back to the grinding chamber because of centrifugal force for re-grinding. Final product is collected by cyclone and bag house.

WFJ series air classifying mill pulverizer has been widely used for milling/pulverizing high fiber content materials, heat sensitive materials and brittle materials in food and chemical industry.

Technical advantages

1. Alloy steel hammer blades and rotor

2. GMP and food grade design

3. Negative working condition can prevent dust and be suitable for heat sensitive material pulverization.

4. Output size is adjustable via air classifier and air flow rate.

5. Feeding rate is automatic controlled

6. Particle size distribution can be accurately controlled

Main Technical parameters

|

Model

|

WFJ-15

|

WFJ-20

|

WFJ-30

|

WFJ-60

|

|

Capacity kg/h

|

10-200

|

20-400

|

30-800

|

50-1200

|

|

Input size mm

|

≤10

|

≤12

|

≤12

|

≤12

|

|

Output size mesh

|

80-350

|

80-350

|

80-350

|

80-350

|

|

Total power KW

|

13.5

|

22.5

|

46

|

84.15

|

|

Rotation speed RPM

|

5800

|

5800

|

3800

|

3200

|

|

Installation dimension mm

|

5410X1660X2500

|

5500X1800X3100

|

9000X2200X4000

|

9000X2700X5280

|

|

Gross weight kg

|

850

|

1200

|

1500

|

3200

|

Detailed Images

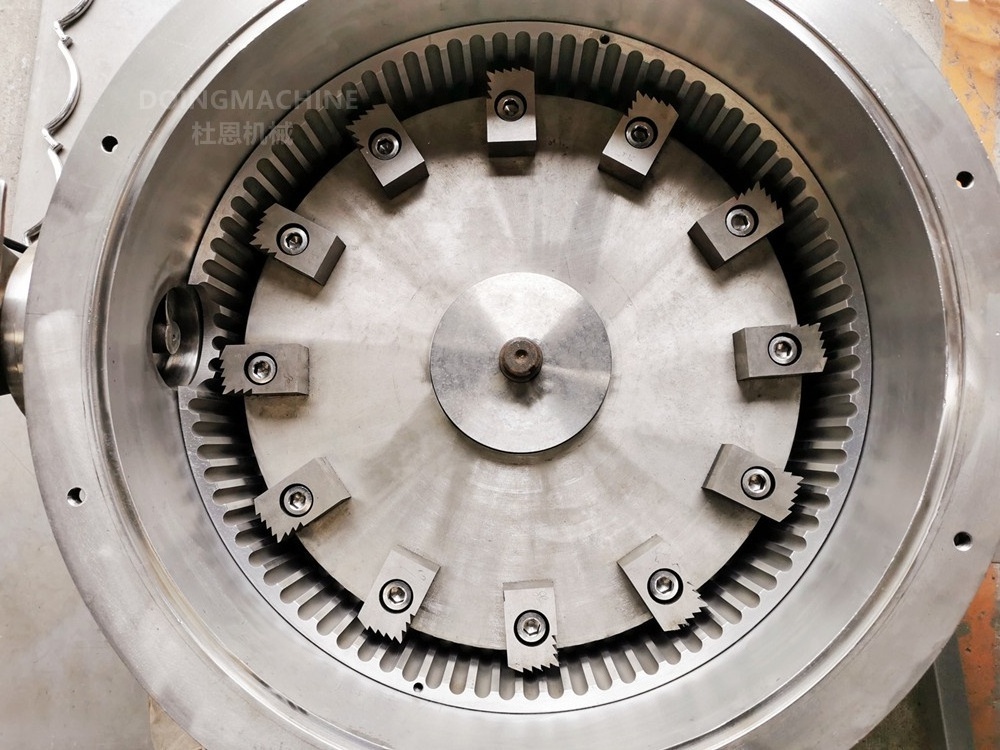

Grinding chamber inside

Alloy steel hammer heads and specially heat-treated

teeth liner can considerablly increase life-span.

Grinding chamber outside

All the motors are well protected for safety and high sanitary working conditions.

Screw feeder

Inverter is equipped to accurately control the

feeding

rate for stable and reliable operation.

Product collecting system

Product collecting system consists of cyclone, bag house and draft fan to prevent dust and increase collection rate.

Packing & Delivery

FAQ

Q: What information should be provided in order to get a proposal or quotation?

A: Each air classifying mill pulverizer is specially designed for each customer according to specific material, capacity, feed material size and product size. Before we can work out a detailed proposal or quotation, we have to know the following information:

1) Detailed information of material are you going to mill. We may ask you to provide simples for grinding test.

2) Size of your material

3) Your required particle size after grinding

4) Grinding capacity in kg/h

Q: How the machine will be delivered ?

A: The system is usually dismantled into grinding chamber, cyclone, bag house, draft fan and control cabinet for shipping. Each part is packed in box made by plywood.

Q: What kind of after sale service you can provide?

A: We have professional after sale service team who can reach you in short notice. They can supervise the installation, do commissioning and train your workers.

Hot Searches