- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

5290 KG, 5290kg

-

Product name:

-

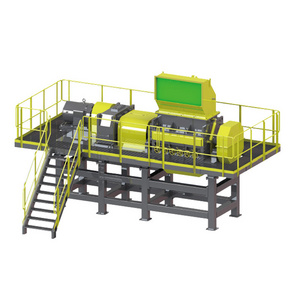

Large scale waste wood fabric tire shredding and crushing equipment

-

Power:

-

129kw

-

Rotation rate:

-

23r/min

-

Capacity:

-

1000-1750kg/h

-

Discharge size:

-

30-92mm

-

Mesh size:

-

21-186mm

-

Voltage:

-

380v

Quick Details

-

Capacity(t/h):

-

1000-1750kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mind

-

Weight:

-

5290 KG, 5290kg

-

Product name:

-

Large scale waste wood fabric tire shredding and crushing equipment

-

Power:

-

129kw

-

Rotation rate:

-

23r/min

-

Capacity:

-

1000-1750kg/h

-

Discharge size:

-

30-92mm

-

Mesh size:

-

21-186mm

-

Voltage:

-

380v

Introductions of Double shaft shredder for bulky waste:

1. The bulky shredder adopts dual-shaft independent drive, which makes the material press correspondingly during the production process, and achieves the automatic feeding function.

2. The unique shift structure and the four corner rotary tool will not cause the shift to ripe or jam the equipment during the production process of low speed and high torque, thus improving the production efficiency.

3. This equipment is suitable for the crashing of a various tough and viscous materials.

4. There are many advantages in production, environmental protection recycling and so on.

|

|

Specifications:

| Model | Capacity(kg/h) | Power(kw) | Dimension(mm) | Weight(kg) |

| 700 | 2000 | 22*2 | 2180*1100*1400 | 2000 |

| 800 | 2000 | 22-75 | 1500*1000*1700 | 1700 |

| 2000 | 2000 | 45 | 2800*4000*4300 | 8500 |

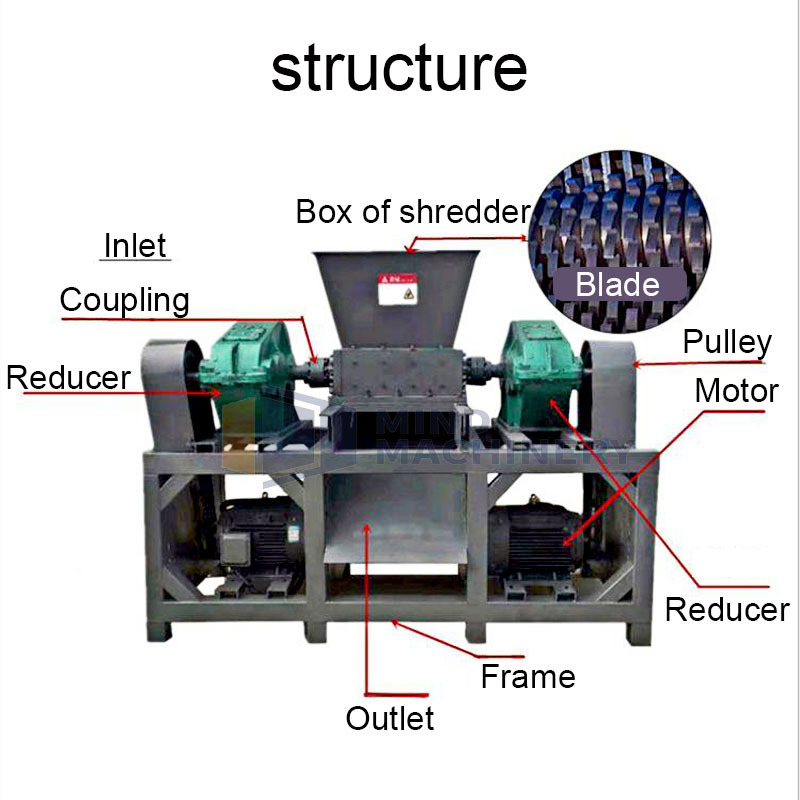

Structures of Double shaft shredder for bulky waste:

|

1. Inlet 2. Box of shredder 3. Pulley 4. Motor 5. Reducer 6. Frame 7. Outlet 8. Reducer 9. Coupling |

|

Working Principles of Double shaft shredder for bulky waste:

1. Fragmentation is achieved by mutual shearing and tearing between two relatively rotating knives.

2. It has many characters such as low speed, high torque, high production capacity, strong power ,high stability,high shear force, good shredding effect and low noise.

3. Larger materials can be cut to a size at one time, such as plastic buckets leather scraps, waste tires waste home applications, expired machines, sofa mattress, waste tires, crop straws, etc..

They can be directly recycled or further refined as needed after being shredding by the double shift shredder

|

Main Features:

1. Reasonable equipment design and good performance

2.Thick equipment sheet, high torque resistance, very strong

3.According to different customer needs, there are variety of configuration tools

to choose from

4.The control system adopts microcomputer(PLC) automatic control, with start, stop, reverse and overload automatic reverse control functions

About our company:About us

1. Henan Mind Machinery Equipment Co., Ltd., a professional enterprise specialized in machinery designing and manufacturing.

2.Since the very begining of our established, we have always taken customer-oriented as our management philosophy.

3. And continuous sound growth makes us striding to well-professional. In the profess of growth we never stop continuous efforts in technology innovation and pioneering.

4. Advanced technology and scientific management make our products the best in term of quality, function, price and after-sales service before sales among this field.

Certifications

Packing&Delivery

Our service

1. Pre-sale service: We can provide you with project design, process design, suitable purchase program for your equipment.

2. Sale service: We will accompany you to visit our factory and all kinds of machinery and equipment if you come here, also show you construction plan and assist in the development process in detail.

3. After Sale service: We will send technicians to the scene to guide the equipment installation, commissioning and training your operating personnel.

FAQ

Q1: Can you give me a solution and quotation?/h2>

Answer: Absolutely sure, we can provide accurate solution and quotation, please give us background information, including, raw material, the capacity, max. input size, the output size, the usage of final products, etc.

Q2: Way of payment

Answer: Welcome clients place the order by alibaba online one-touch! Mind also offers various ways of payment, T/T, against copy of B/L, L/C, D/A, D/P, West union, etc. All can be negotiated.

Q3: What’s the delivery time after I pay the deposit ?

Answer: Normal delivery time within 10 to 20 working days, complete production line or larger equipment may take longer. Exact delivery shall be confirmed when place the order

.

Contact us

Related Products

| Impact crusher | Jaw crusher | Magnetic separator |