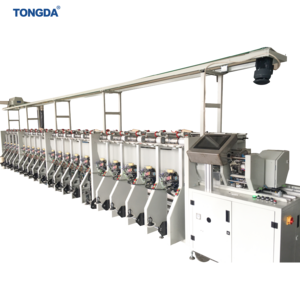

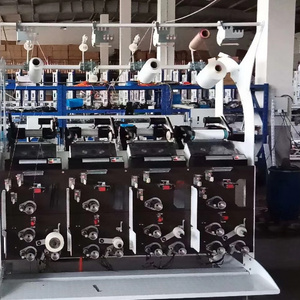

SMARO-NEW automatic winder inherits the advantags of Smaro series winder, adopts brand-new profile design, featured by beautiful and dignified, adopts the brand-new smart anti-pattering device, new type of tension control system and new type of balloon centrol mechanism to ensure perfect package building, more even winding tension, high machine opteration stability and reliability to meet customer requirement.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Smarto

-

Voltage:

-

380V

-

Power:

-

33.57

-

Dimension(L*W*H):

-

2267x1365x2650mm

-

Weight:

-

5000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

winding speed:

-

400-2200 m/min

-

Spindle number:

-

6-72

-

Spindle gauge:

-

320mm

-

grooved drum turns:

-

2 or 2.5

-

Type:

-

single spindle, single sided arrangement, left or right hand

Quick Details

-

Application:

-

Winding Yarns

-

Production Capacity:

-

100%

-

Memory Capacity:

-

Request

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Smarto

-

Voltage:

-

380V

-

Power:

-

33.57

-

Dimension(L*W*H):

-

2267x1365x2650mm

-

Weight:

-

5000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

winding speed:

-

400-2200 m/min

-

Spindle number:

-

6-72

-

Spindle gauge:

-

320mm

-

grooved drum turns:

-

2 or 2.5

-

Type:

-

single spindle, single sided arrangement, left or right hand

Smaro Series Automatic winder

Anti-patterning system

New type of electronic anti-pattering system, adopting balance pressure regulating in ratio, functions during the whole winding process to eliminate the formation of critical patterned yarn. Multi-type of drums optional for different yarns meet the requirement of package building and capacity.

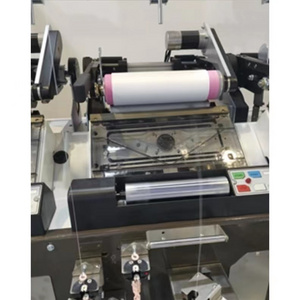

Closed drum cover

New type of closed drum cover can efficiently prevent package yarn tail from throwing off, greatly reduce yarn wrap on small bobbin side, prevent bobbin building problem, enhance one-time head suction successful rate, Electronic anti-wrap drum can prevent yan wrap on drum and stepped winding yarn, optimize package building and reduce material waste.

Close-loop control

Newly increased tension close-loop control ensures even doffing tension, enhance winding speed 10-20% and production efficiency 2-5%.

DC brushless motor

Comparing with traditional belt drive, DC brushless motor coaxial drive winding drum could reduce the electricity comsumption and improve the productivity due to the elimination of the power loss caused by belt friction and slipping.

Electronic clearer controls

Electronic clearer controls yarn quality, including yarn joint quality, during the whole winding process, two different yarn cleaner settings are adopted for normal yarn winding and joint respectively. The most advanced electronic yarn models can be equipped. Foreign fiber detecting function can be close as optional.

Splicing system

Splicing system adopts modular-design for easy installation and maintenance. Different types of splicers can be interchanged according to different customer requirement.

|

Type

|

Single-spindles, single-sided arrangement, left or right hand

|

|

Application

|

Nm 3.5 to the highest count cotton, wool, synthetic yarn and blended single yarn

|

|

Number of winding spindles

|

6-72 every two spacing increment

|

|

Spindle distance

|

320mm

|

|

Applicable bobbin typer

|

4 degree20 and 5 degree 57

|

|

feeding bobbin diameter

|

32-72mm

|

|

feeding bobbin length

|

180-300mm

|

|

Joint type

|

Airsplicer, aquasplicer

|

|

Magazine type

|

6 holes or 9 holes

|

|

Joint type

|

The lastest USTER/ LOEPFE electronic yarn clearer

|

|

Circles on drum

|

2 or 2.5

|

|

Tension control

|

Electromagnetic pressure

|

Established in 1952,our company has been specializing in designing,manufacturering and marketing of a full range of textile machinery for many years.We have five branch companies now.

Our main products are that blow room/cotton carding machinery/draw frame/roving frame/rotor spinning machinery/ring spinning machinery/water jet loom/nonwoven machinery etc.

As for the details you can reference www.china-tongda.com

We are gold member of alibaba, you can search “ Shandong Tongda Textile Machinery” from alibaba then you can see us.

All the products are certified by the Industy Administration Authority.We are enjoying an excellent repution in the world market with perfect products and low price.

About Payment Terms:

We accept the following payment methods: T/T & L/C.

About Photos:

All products' photos are true and taken carefully by our Graphic Designer Team.

About After-Sales Service:

Our goal is Good,better,best,never let it rest. & Our service purpose is try our best to make customers satisfied.

Professional team will solve any problems you met during the whole purchasing progress.