Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Dibaier

-

Model Number:

-

sandwich panels

-

Product name:

-

pu external wall metal insulation board panel

-

Surface Material:

-

Steel Sheet/Aluminum Sheet

-

Color:

-

White, gray, brown, blue, red, etc.

-

Length:

-

2000---6000 mm

-

Width:

-

383 mm

-

Thickness:

-

16mm/20mm

-

Weight:

-

3.5kg/m2

-

Core material:

-

PU Polyurethane 40 kg/cube meters

-

Advantage:

-

Light Weight

-

Usage:

-

exterior wall decoration/outdoor

Quick Details

-

Project Solution Capability:

-

graphic design, Others

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Dibaier

-

Model Number:

-

sandwich panels

-

Product name:

-

pu external wall metal insulation board panel

-

Surface Material:

-

Steel Sheet/Aluminum Sheet

-

Color:

-

White, gray, brown, blue, red, etc.

-

Length:

-

2000---6000 mm

-

Width:

-

383 mm

-

Thickness:

-

16mm/20mm

-

Weight:

-

3.5kg/m2

-

Core material:

-

PU Polyurethane 40 kg/cube meters

-

Advantage:

-

Light Weight

-

Usage:

-

exterior wall decoration/outdoor

Metal sandwich panels for exterior walls are a new type of thermal insulation and decorative panels for exterior walls in China. Although the metal carving board is a new type of thermal insulation and decoration material in China, it has been widely used in Japan, South Korea and other places abroad.

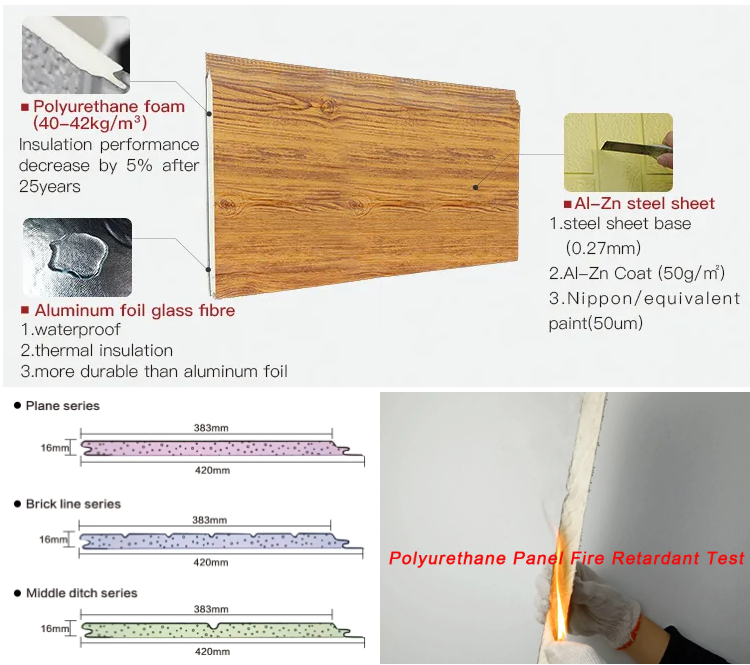

The metal carved board adopts environmentally friendly raw materials: the surface is made of high-quality galvanized steel plate treated with a special layer (55% aluminum, 43% zinc); high-density foamed polyurethane is used as the intermediate core material, and its closed cell rate is as high as 99.6 % (polyurethane sandwich is the same material as the inner insulation layer of refrigerators and air conditioners), green and pollution-free, giving the building green protection and decoration; the bottom surface is an aluminum foil cloth protective layer that plays the role of heat insulation, heat preservation, fire prevention and moisture resistance, which can reach 15 It does not fade for years, and its service life is as high as forty or fifty years. The metal carved board itself has the characteristics of beautiful decoration, thermal insulation, fire and moisture resistance, light weight and shock resistance, convenient construction, sound insulation and noise reduction, green environmental protection, etc. It is very safe and convenient to install and use, and is suitable for all seasons.

Metal carved panels for exterior walls are a new type of thermal insulation and decorative panels for exterior walls in China. Although the metal carving board is a new type of thermal insulation and decoration material in China, it has been widely used in Japan, South Korea and other places abroad.

The metal carved board adopts environmentally friendly raw materials: the surface is made of high-quality galvanized steel plate treated with a special layer (55% aluminum, 43% zinc); high-density foamed polyurethane is used as the intermediate core material, and its closed cell rate is as high as 99.6 % (polyurethane sandwich is the same material as the inner insulation layer of refrigerators and air conditioners), green and pollution-free, giving the building green protection and decoration; the bottom surface is an aluminum foil cloth protective layer that plays the role of heat insulation, heat preservation, fire prevention and moisture resistance, which can reach 15 It does not fade for years, and its service life is as high as forty or fifty years. The metal carved board itself has the characteristics of beautiful decoration, thermal insulation, fire and moisture resistance, light weight and shock resistance, convenient construction, sound insulation and noise reduction, green environmental protection, etc. It is very safe and convenient to install and use, and is suitable for all seasons.

Quick Details

|

Attributes |

|

|

Warranty |

3years |

|

After-sale Service |

Online technical support |

|

Project Solution Capability |

graphic design, 3D model design |

|

Application |

Villa |

|

Place of Origin |

China |

|

Brand Name |

DIBAIER |

|

Use |

Carport, Hotel, House, Kiosk,Booth, Office, Sentry Box,Guard House, Shop, Toilet, |

|

Product Type |

Container Houses |

|

Design Style |

Modern |

|

core material |

pu foam |

|

wall cladding |

Hot dip galvanized steel sheet |

|

Application |

insulation and decoration |

Significant energy-saving effect

1. The surface material of the panel is aluminized zinc sheet which the thickness is 0.27-0.30mm.

Its weather resistance, acid resistance, alkali resistance, smoke resistance after special process treatment. The surface layer is

greatly enhanced by the pressure balance principle and percent recovery is 99.9%.

2. Rigid polyurethane foam is the most environmentally friendly insulation materials in the world. Its insulation performance

decreased only less than 3% after 25 years under high temperature testing. Compared with traditional materials, it has excellent

heat insulation and cold resistance performance. The heating and cooling energy consumption is greatly reduced thus saving energy

expenditure, cost-effective.

3. Its unique design structure completing elimination of the "cold and heat bridge effect". Effectively avoiding indoor moisture,

mildew and other phenomena. At the same time, as the panel is installed on the external wall of the building so avoiding the

damages to the whole structure which caused by rain and snow weather and other natural factors.

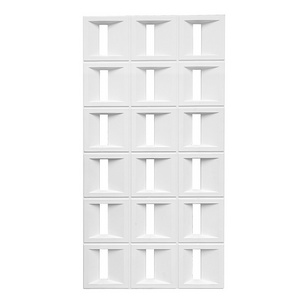

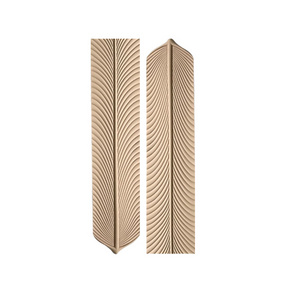

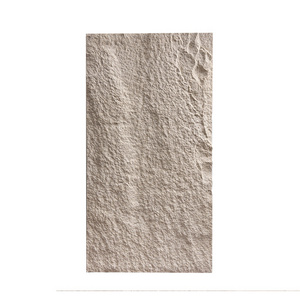

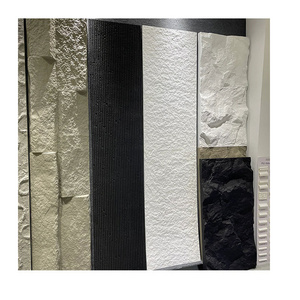

Perfect decorative effect

The surface can be made into a variety of different textures like brick, stone, mosaic, (wood) grain etc. A variety of colors and

patterns can meet the requirements of different architectural style.

|

Sheet name |

Polyurethane wall panel |

|

Effective lap (mm) |

1000mm |

|

Plate thickness (mm) |

50/75/100/120/150/200 |

|

Color plate thickness (mm) |

0.4-0.8 |

|

Optional panels |

Color coated steel, stainless steel, galvanized steel |

|

Regular colors |

White gray, large wall gray, dark blue |

|

Plate effect |

flat, embossed, small ripples, pressure ribs |

Metal carved sandwich panel is easy to install with accessories.Carved metal panel accessories : Starting part installation diagram,Door/window frame cover installation diagram,Big outside corner cover installation diagram,Closing part installation diagram,Center joint installation diagram,Inside/outside corner cover installation diagram.

Polyurethane sandwich panel has light weight, beautiful appearance and good anti-corrosion performance, and can be directly processed. It provides a new type of raw material for the construction industry, shipbuilding industry, vehicle manufacturing industry, furniture industry, electrical industry, etc., and has played a good role in replacing wood with steel, efficient construction, energy conservation, and pollution prevention

Modern architectural decoration pursues various forms. In order to satisfy people's pursuit of beauty, decorative wall panels have gradually become the mainstream of exterior wall decoration. This demand has also been reflected on many social media platforms. The playback volume of a single video is more than 3 million, and it is still growing, which reflects people's constant pursuit of beauty and comfort.

Modern architectural decoration also pursues a variety of shapes. In order to satisfy people's pursuit of beauty, decorative wall panels have become the mainstream of exterior wall decoration. The insulation panel material is different, and the decorative wall decoration is different. In addition to decoration, people in different regions pay different attention to exterior insulation panels. People in high-temperature areas care about UV protection and heat insulation; people in low-temperature areas pay more attention to the thermal insulation ability of external insulation panels; residents in rainy areas pay more attention to potholes and external tidal energy; residents around forests care about whether they are insect-proof and anti-fungal, and algae growth. The decorative insulation sandwich panel we produce not only highlights the decorative function, but also solves the above-mentioned plight of the residents, and is very popular among the public. This article will take you through how to use this insulation panel DIY beauty room wall. If you haven't done it before, don't be fooled: with a little know-how, you can slap a speed board with ease and get great results.

How to install decorative insulation sandwich panels (DIY)?

Installing decorative siding is an easy task with BFT wall panels, It's as simple as putting together blocks.Billy Baldwin: "The first rule about decorating is that you can break almost every other rule."

Before you begin, the essentials you will need include:

1. decorative insulation sandwich panel 2. Accessories

1. Tape measure 2. Handsaw/chainsaw 3. Laser Level 5. Pistol Drill 6. Electric hammer 7. Styrofoam Decorators caulk 8. Plastic expansion tube 9. Wood screws 10. Pen and paper 11. Calculator

Step 1: calculate the number of decorative siding needed

First measure the area of the wall to be decorated and calculate the number of panels. The effective width of the wallboard is 38.3cm, and the number of wallboards required can be known by calculating the wall area. At the same time, because of the fixed size of the board, some material waste rate needs to be added to ensure sufficient material.

Step 2: Calculate the type and length of the accessories used for the wall panel

Before installing insulation panels, you need to decide how the panels will connect. You can use the starting piece, the middle joint piece, and the closing piece of this kind of wallboard for connection. These accessories will not affect the decorative effect of the wallboard, and at the same time can ensure that the wallboard is very stable during installation. Plan the plug-in method and location of accessories. And mark it with a pen.

Step 3: Prepare the Wall Panels

Before installation, the insulation panels need to be prepared. Cut the insulation panels to size with a hand saw and leave to dry to ensure that the bonding area is dry and smooth.

Step 4 Prepare accessories

Cut the accessories according to the length of the wall with a hand saw.