Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

30 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Vina

-

Voltage:

-

380V,50Hz or Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

120

-

Weight:

-

36000 KG

-

Product Type:

-

Pvc Profile Extrusion Machine

-

Raw material:

-

PVC Powder+additatives

-

Automatic Grade:

-

High Automation

-

Color:

-

Customers' Require

-

Motor:

-

Siemens Beide

-

Inverter:

-

ABB Brand

-

Screw type:

-

Twin Conical Screw

-

Temperature control:

-

Omron Brand

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

Other

-

Screw diameter (mm):

-

Other

-

Screw Speed (rpm):

-

30 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Vina

-

Voltage:

-

380V,50Hz or Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

120

-

Weight:

-

36000 KG

-

Product Type:

-

Pvc Profile Extrusion Machine

-

Raw material:

-

PVC Powder+additatives

-

Automatic Grade:

-

High Automation

-

Color:

-

Customers' Require

-

Motor:

-

Siemens Beide

-

Inverter:

-

ABB Brand

-

Screw type:

-

Twin Conical Screw

-

Temperature control:

-

Omron Brand

Products Description

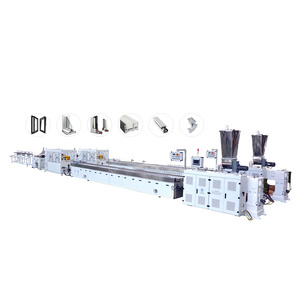

PVC Profile production line consist of conical twin screw extruder , vacuum shaping table , hauling off machine and cutter, stacker

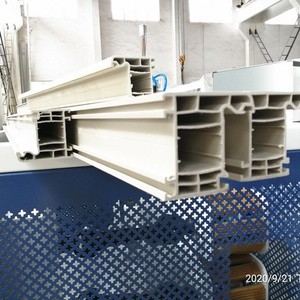

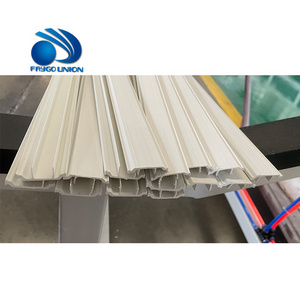

This production line is mainly used to produce PVC profile, such as Ceiling, Deck, Floor, Cornice, Plank, Windows, Door frame and board and etc

This production line is mainly used to produce PVC profile, such as Ceiling, Deck, Floor, Cornice, Plank, Windows, Door frame and board and etc

(1)High shrink surface, smooth without gap when concatenated

(2)Fireproof, moisture-proof, mold-proof, waterproof, soundproof, sound-absorbing, light in weight and easy installation

(3)For ceiling, wall decoration, windows , door profile and cable trunking profile

(4)The variety of colors and patterns

Production process:

Screw Loader for Mixer---High Speed Mixing Unit---Screw Loader for Extruder---Conical twin screw extruder---Mold---Vacuum calibration table---Haul off&Cutting machine---Stacking Table.

According to different needs and configurations, our company also sell auxiliary machines for relevant production lines. For details, please contact our customer service to provide customized solutions for you

Details Images

High speed mixing unit

Used for different density of powder/particles/additives/color powder/color master/plastic and other materials mixing and mixing

evenly, in order to adapt to the mixing requirements of some raw materials, the equipment is equipped with insulation device, can be used for cooling, heating and insulation of raw materials.

evenly, in order to adapt to the mixing requirements of some raw materials, the equipment is equipped with insulation device, can be used for cooling, heating and insulation of raw materials.

Screw Loader

Used for raw material feeding to extruder, mixing machine

Loading control: time relay automatic control

Conical twin screw extruder

The solid material is plasticized and fused into a uniform temperature melt and continuously extruded

• World famous brand electrical component such as Siemens,Schneider, ABB etc;

• High torque gearbox with adopts NSK/SKF bearing;

• Siemens/WEG original motor achieved global after service;

• Bimetallic screw and barrel;

• Intelligent PLC controlling system with human-friendly interface.

Extrusion mould

Change the shape of the molding material through the mold

• 3Cr13/3Cr17 material;

•Complete set include extrusion die head, calibrator and cooling tank;

• Apply to soft PVC, rigid PVC,

soft-hard co-extrusion profile, foamed profile, multi-layers co-extrusion etc.

soft-hard co-extrusion profile, foamed profile, multi-layers co-extrusion etc.

Vacuum Calibration Table

After exit from the die head, enter the cooling mold immediately. The mold is vacuized, so that the outer wall of the profile and the surface of the molding mold are tight, and the water is cooled by the molding sleeve. The adsorption force of the vacuum is required and uniform, so as to ensure the appearance and dimensional precision and apparent quality of the profile.

• Include full set of vacuum and water pump;

• Length from 4m-11.5m;

• Independent operation panel for easy operation.

Caterpillar Haul off machine

After the extruder extrudes the raw material through the mold. The tractor clamps the profile from its outlet and then pulls it to a certain length, which reaches the predetermined extruded length

• Upper and lower caterpillar is driven separately and speed control by frequency inverter;

• Fast change type pads for easy operation;

• Install plate is adopts aluminum material;

Cutting Machine

The continuous extrusion products are cut into a certain length by the cutting machine according to the requirements

• Compacting driving by pneumatic;

• Tracking cutter or lifting saw cutter with adopts double station dust collection system;

• Synchronous driving by air cylinder or servo motor control.

Product collection and placement machine

Collect and arrange the cut product

• Stainless steel304 as touching material;

• Discharge driving by air cylinder.

Test machine sample display

Product Paramenters

|

Max profile width (mm)

|

Extruder model

|

Designed capacity(kg/h)

|

Extruder motor power(kw)

|

circulating cooling water

consumption(

m³

/h)

|

Compressed air consumption(m³/h)

|

|

180

|

51/105 or 55/110

|

80-120/120-150

|

18.5/22

|

9

|

0.3

|

|

240

|

65/132

|

175-250

|

37

|

11

|

0.4

|

|

300

|

65/132

|

175-250

|

37

|

11

|

0.4

|

|

400

|

65/132 or 80/156

|

175-250/250-350

|

37/55

|

12

|

0.5

|

|

600

|

65/132 or 80/156

|

175-250/250-350

|

37/55

|

12

|

0.5

|

|

800

|

80/156

|

280-350

|

55

|

13

|

0.6

|

|

1000

|

92/188

|

450

|

110

|

15

|

0.8

|

|

1250

|

92/188

|

450

|

110

|

18

|

1

|

|

Technical Parameter of Main extruder

|

|

|

|

|

|

|

|

|||||||

|

Model

|

Power

(kw)

|

Screw Diameter (mm)

|

Screw Qty

|

Screw rotation speed(rpm)

|

Designed Output (kg/h)

|

Center Height (mm)

|

Dimension(L*W*H)

(mm)

|

|||||||

|

45/90

|

15

|

Φ45/90

|

2

|

34.7

|

70

|

1050

|

3360*1290*2127

|

|||||||

|

51/105

|

18.5

|

Φ51/105

|

2

|

34.7

|

100

|

1050

|

3360*1290*2127

|

|||||||

|

55/110

|

22

|

Φ55/110

|

2

|

34.7

|

150

|

1050

|

3620*1050*2157

|

|||||||

|

65/132

|

37

|

Φ65/132

|

2

|

34.7

|

300

|

1050

|

3715*1520*2450

|

|||||||

|

80/156

|

55

|

Φ80/156

|

2

|

34.7

|

400

|

1050

|

4750*1550*2460

|

|||||||

|

92/188

|

110

|

Φ92/188

|

2

|

34.7

|

750

|

1250

|

6725*1550*2814

|

|||||||

Product packaging

Packaging & Shipping:

1.For the loose cargo we will packing by wooden box

2.For the full container loading we are packing the machine by film and some on pallet accordingly

3.We can shipping the goods by air or by sea

4.We will send pictures of cargo loading to our client to check and keep recording

5.We can send cargo to client's warehouse to loading

6.We have free spare parts with the machine.

2.For the full container loading we are packing the machine by film and some on pallet accordingly

3.We can shipping the goods by air or by sea

4.We will send pictures of cargo loading to our client to check and keep recording

5.We can send cargo to client's warehouse to loading

6.We have free spare parts with the machine.

FAQ

Q:Are you machinery factory or trading company?

A:We have our own factory,which means we can strictly guarantee product quality and lead time.

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Do you provide material testing service?

A:We have our own factory,which means we can strictly guarantee product quality and lead time.

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Do you provide material testing service?

A: Yes, we offer testing service on our machine. An additional testing fee will be charged depends on the testing costs(electricity, labor), however, if you eventually made a purchase with us ,the testing fee will

counts to deduction of machine purchase cost.

Q: How can I make sure the machine running good in my plants?

counts to deduction of machine purchase cost.

Q: How can I make sure the machine running good in my plants?

A: First we will have a home commissioning in our factory for your inspection. If you need assistance in installing and staff training , we can also send engineers to service overseas and solve all problems. (notice: return flight and $80 per day salary will be on customer)

Q: How to get a quote efficiently?

Q: How to get a quote efficiently?

A: Please kindly click on ' Sent An Inquiry ' Button at the bottom of page,or click "Chat now"on the right side of the page. Leave a message to describe details of your final products ( better with a picture and size drawing), Capacity requirements, We will reply to your inquiry within 12 hours

Q: How can we visit your company and machines?

A : Our factory is in Jinfeng Town, Zhangjiagang City, Jiangsu Province, China. About 2.5hours from Shanghai Pudong International Ariport.

Q:What`s the payment method?

A: T/T, L/C,Western Union,etc

Q: How can we visit your company and machines?

A : Our factory is in Jinfeng Town, Zhangjiagang City, Jiangsu Province, China. About 2.5hours from Shanghai Pudong International Ariport.

Q:What`s the payment method?

A: T/T, L/C,Western Union,etc

Hot Searches