- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1-100 kw

-

Dimension(L*W*H):

-

5.9*2.3*2.3

-

Weight:

-

2000 KG

-

Machinery Function:

-

Making chocolate

-

Output product name:

-

Chocolate Bar

-

Item:

-

Small chocolate processing machine

-

Capacity:

-

20 kg 40 kg 50 kg 100 kg

-

Useage:

-

Making chocolate

-

Material of machine:

-

Stainless steel

-

Export countries:

-

Arica, Soush America, North America

-

Keywords:

-

chocolate making machine

-

Function:

-

transform cocoa beans

-

After Warranty Service:

-

Online support

Quick Details

-

Brand Name:

-

SUNRISE

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220/380 V

-

Power:

-

1-100 kw

-

Dimension(L*W*H):

-

5.9*2.3*2.3

-

Weight:

-

2000 KG

-

Machinery Function:

-

Making chocolate

-

Output product name:

-

Chocolate Bar

-

Item:

-

Small chocolate processing machine

-

Capacity:

-

20 kg 40 kg 50 kg 100 kg

-

Useage:

-

Making chocolate

-

Material of machine:

-

Stainless steel

-

Export countries:

-

Arica, Soush America, North America

-

Keywords:

-

chocolate making machine

-

Function:

-

transform cocoa beans

-

After Warranty Service:

-

Online support

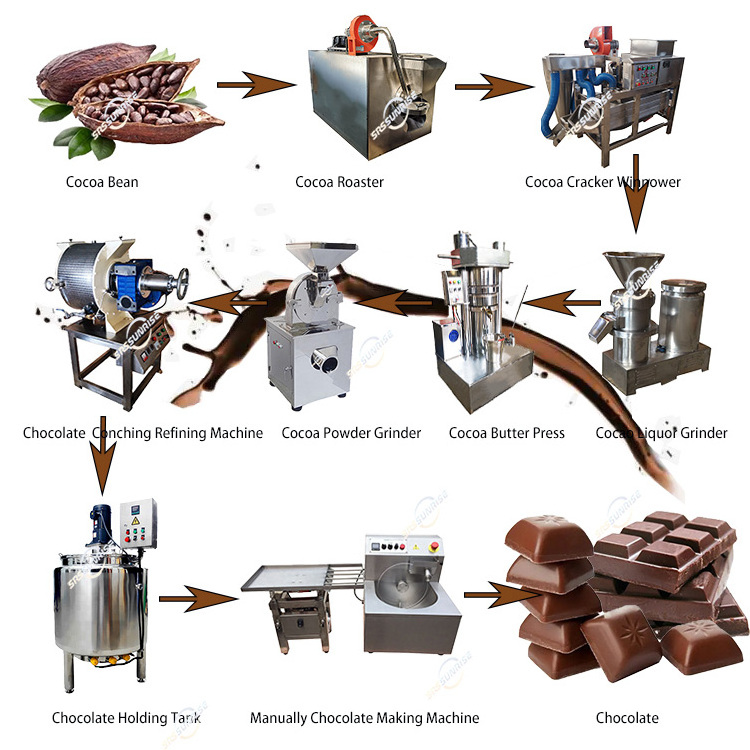

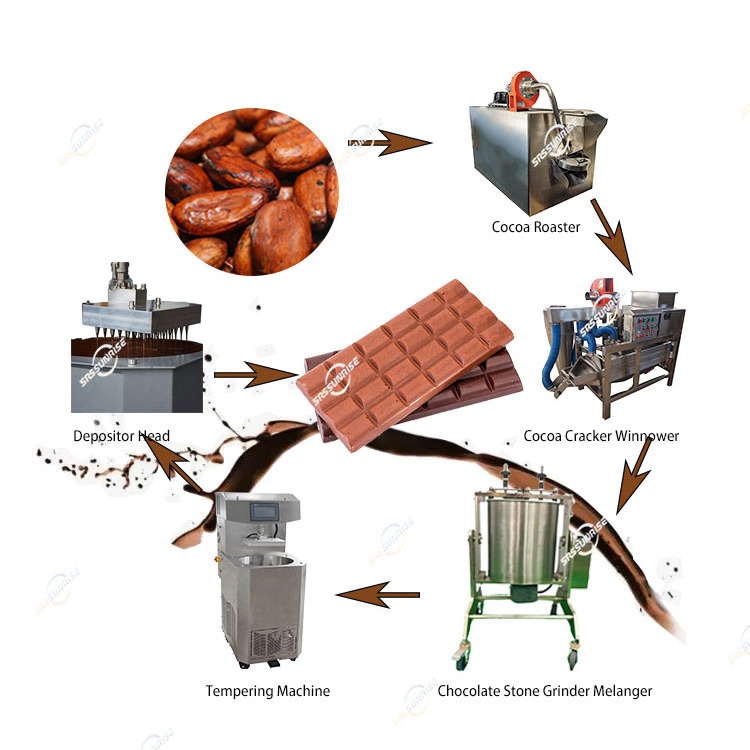

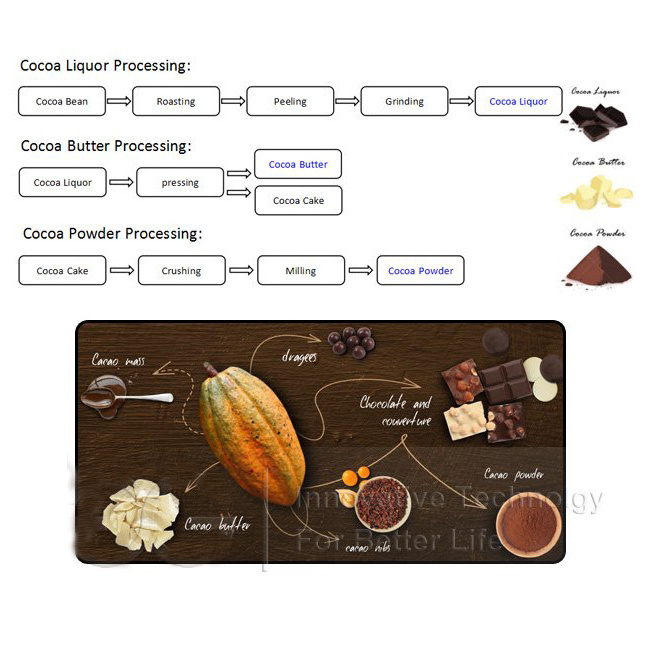

Flow Chart Of Cocoa Processing Line

Cocoa Processing And Production Technology.

1. Harvesting/Cleaning

As with many other tropical crops, the cocoa harvest is spread over several months, usually with a major peak and a minor peak of pod ripeness/harvesting.

Careful removal of the pods from the trees with a knife is required to avoid damage to the flower cushions.

After inspecting and conducting the necessary tests to ensure compliance with international standards and regulatory requirements, the cocoa beans cleaning process takes place.

The inside of an undamaged cocoa bean is clean in all respects (removal of foreign material ranging from machete blades to shotgun shells), and will remain so as long as it is stored properly and is not mixed with contaminated materials not completely removed during cleaning or subsequent steps downstream.

2. Fermentation

Chocolate flavour is developed in two parts: the first is on the farm through correct fermentation of the wet beans by the grower, and the second by the processor in the factory at the roasting step. Good chocolate flavour cannot be produced by adhering to only one of these stages.

In the initial stages of fermentation, much of the pulp drains away and sometime between 36 and 72 hours the beans are fermented. The processes of flavour development are complex, and still quite poorly understood, though good progress has been made recently through the use of expert analytical and sensory evaluation (flavour profiling) techniques.

3. Drying

After fermentation, the moisture content of the beans needs to be reduced from 55% to 7.5% – an appropriate moisture content for secure storage of cocoa for a couple of months in the tropics. Smallholders lay the wet beans on raised bamboo mats or, less satisfactorily (for hygiene considerations), on concrete platforms on the ground in the villages.

The duration of the drying step depends on the weather, but it is unusual for sun-drying in West Africa, for example to be completed in less than a week.

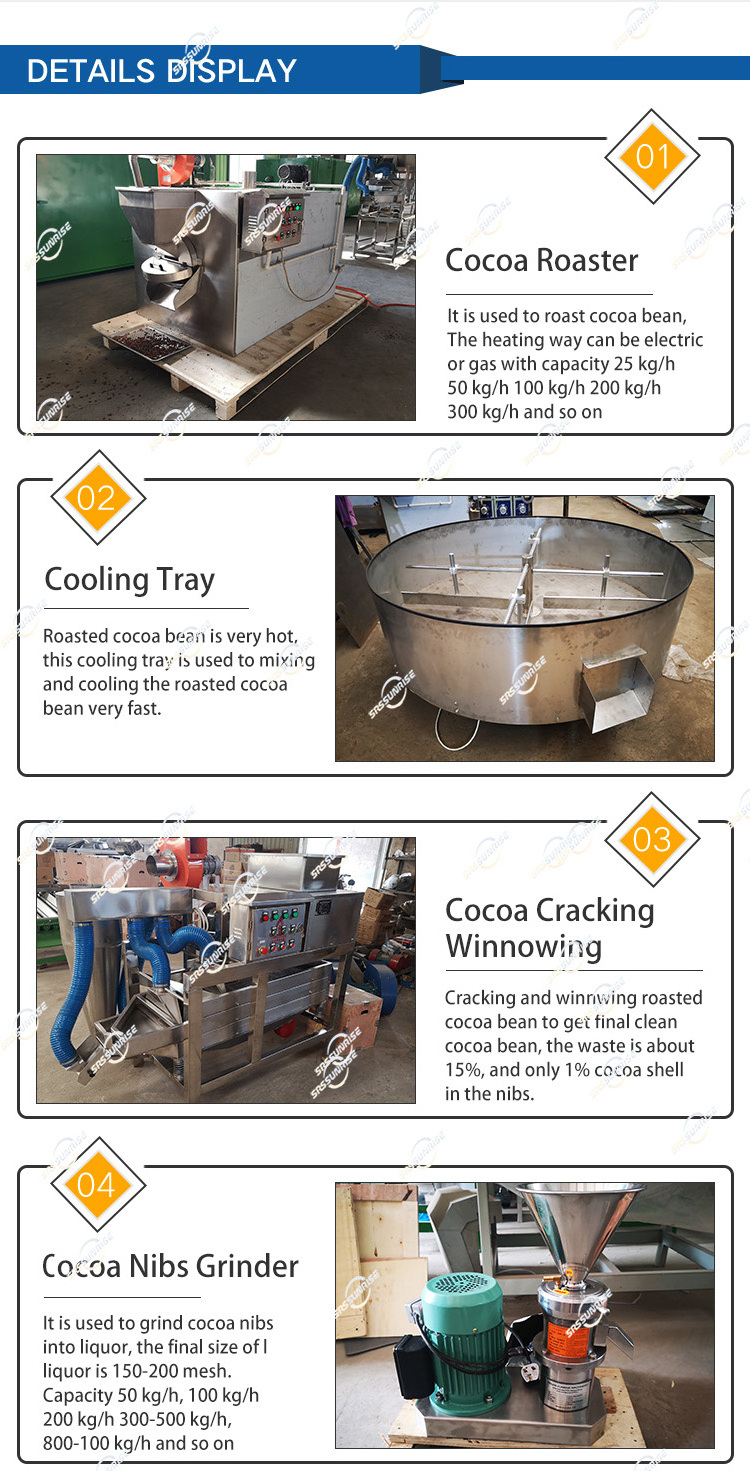

4. Roasting

Roasting cocoa beans can be described as an individual process. While all manufacturers have a similar goal of making products efficiently, the flavour objectives for cocoa liquors usually differ from company to company and from country to country.

Therefore, the flavour target is a key factor in determining the type and blend of cocoa beans to be processed, whether to roast whole beans or nibs, the type of roasting equipment and the roasting parameters employed.

In a nutshell, there is not a right or wrong roast level nor is there a correct or incorrect way to obtain the target roast level. The correct way to roast and the proper roast level is the process which provides nibs in an efficient and cost-effective manner with the chosen flavour system and yields products meeting consumer needs in a specified market.

5. Winnowing

Winnowing, cracking, fanning and hulling are some of the terms and phrases which describe the separation of the shell (hull) and meat of the bean (nib). It is a process where obtaining a clean separation of the two components is driven by economics, product integrity and, in many countries, government regulation.

6. Nibs grinding

Nibs grinding has seen many advances in the last half of the 20th century. Before liquor mills, one method of grinding nibs was mixing nibs with granulated sugar and placing the mixture in a mélangeur. This process yielded a material with consistency ranging from a paste to a fluid.

7. Alkalization

The alkalizing process is optionally applied to modify the flavour and colour of chocolate liquors and cocoa powders. It is also known as Dutch processing. The process consists in mixing the selected cocoa material (cocoa cake, nibs or cocoa liquor) with an aqueous solution of a specific alkaline compound and mixing at elevated temperatures and possibly increased pressures.

Common alkaline compounds are potassium carbonate, calcium carbonate and sodium hydroxide. The resulting product colour ranges from light red to charcoal black.

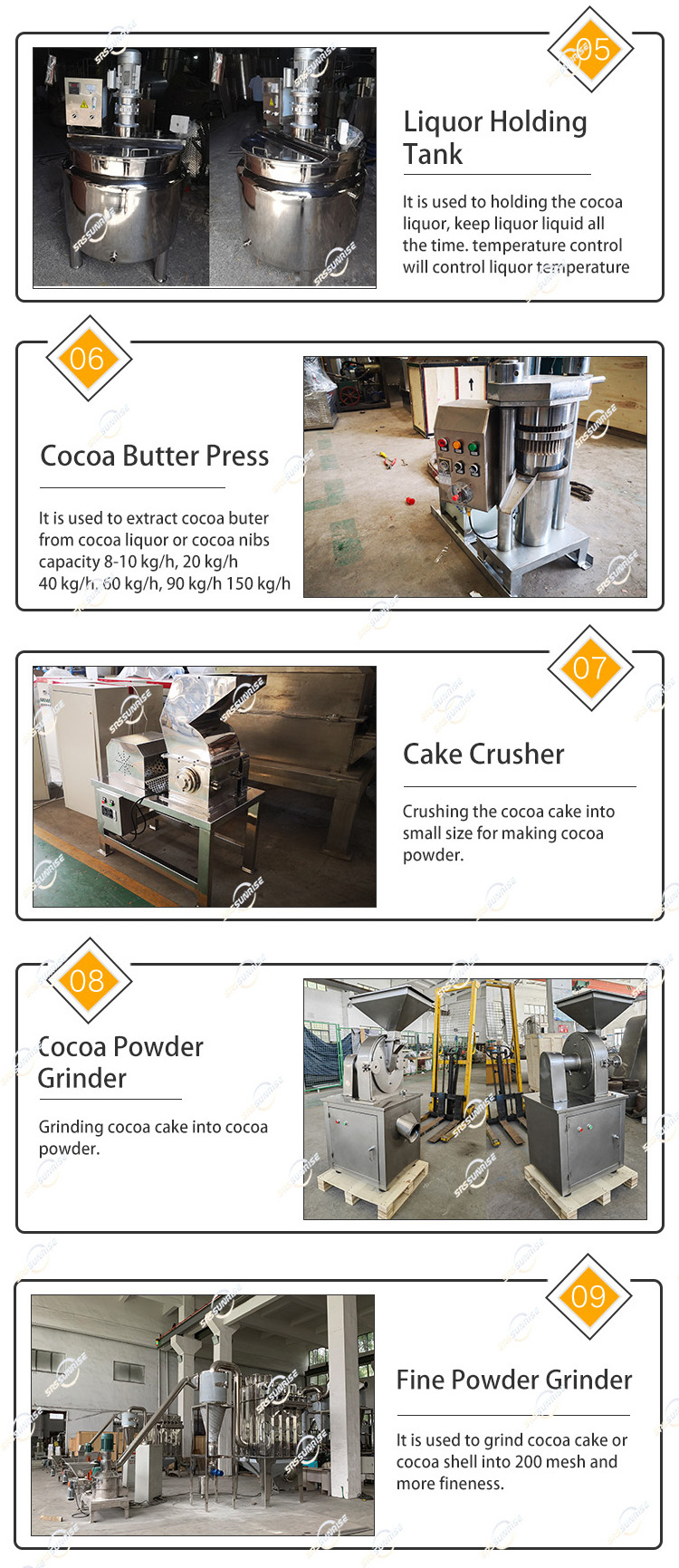

8. Liquor pressing

Typically, the separation or pressing process begins by pumping hot cocoa liquor (200 degrees Celsius) into a horizontal hydraulic press with operating pressures of up to 550 bars.

The cocoa cake formed from this pressing operation is then broken and milled to specified particle sizes as determined by end use.

9. Cocoa grinding

Before grinding of the pressed cocoa cake can begin, it must go through a series of cooling steps. The hammer mill and disc mill are the common mill being used by the industry and a classifier is usually included as part of the system to improve grinding efficiency.

In reality, the term grinding is misleading. The particle size of the finished powder is dependent upon the particle size of the cocoa liquor pressed. Commonly used mills do not reduce the particle size of the cake; instead they tend to break up agglomerates.

It must also be mentioned that cocoa powder must be tempered. This is a sort of controlled cooling operation during which the powder is held at specified temperatures for predetermined times to allow for the cocoa butter to form into a stable crystal configuration. The powder should then be stored properly if it is to maintain its colour and remain soft and in a flowable state.

10. Cocoa butter

The other product obtained from pressing cocoa liquor is cocoa butter. This is the most expensive of the major ingredients in a chocolate recipe.

Cocoa butter colour can be an excellent indicator of potential problems. For example, shipments that are dark brown rather than golden in colour warrant further testing. It can indicate improper handling during processing and storage.

11. Chocolate manufacturing

Cocoa liquor, cocoa butter and sugar are the three major ingredients required to produce the various types of chocolate found throughout the world.

Overall, the manufacturing of chocolate is divided into four areas:

Batching, which is the combining of cocoa liquor, sugar or sweeteners, milk powder (if a milk chocolate), cocoa butter and non-volatile flavoring materials as specified by a recipe or formula.

The particle reduction of chocolate ingredients is required to produce the smooth product most consumers expect.

Conching is a complex process that has been, and continues to be studied in great detail in an effort to fully understand changes (particularly in the flavor of chocolate) that occur in chocolate during this process

Standardization which is the step where the viscosity of the chocolate is adjusted with the addition of fats, usually cocoa butter, and emulsifiers. Volatile flavoring materials may also added at this point.

Production Specification Of Cocoa To Chocolate Bar Processing Machine

Technical Data Of Cocoa Equipment

|

Item

|

Capacity

|

Model

|

Motor power

|

Weight

|

|

Cocoa Roaster

|

20 kg/h

|

ZC-25

|

0.37 kw

|

75 kg

|

|

|

40-50 kg/h

|

ZC-50

|

0.37 kw

|

105 kg

|

|

|

80-100 kg/h

|

ZC-100

|

0.75 kw

|

125 kg

|

|

|

100-200 kg/h

|

SRS-1

|

1.1 KW

|

500 KG

|

|

|

200-400 kg/h

|

SRS-2

|

2.2 KW

|

1000 KG

|

|

|

300-600 kg/h

|

SRS-3

|

3.3 KW

|

1500 KG

|

|

|

500-1000 kg/h

|

SRS-5

|

5.5 KW

|

2500 KG

|

|

Item

|

Capacity

|

Model

|

Motor power

|

Weight

|

|

Cocoa Cracker Winnower/Peeler

Machine

|

50 kg/h

|

DX-50

|

0.37 kw

|

80 kg

|

|

|

100-150 kg/h

|

DX-150

|

0.55 kw

|

180 kg

|

|

|

300-350 kg/h

|

DX-350

|

0.75 kw

|

290 kg

|

|

Item

|

Model

|

Capacity

|

Power

|

Weight

|

|

|

SRS-50

|

30-50 KG/H

|

2.2 KW

|

50 kg

|

|

|

SRS-80

|

500-100 KG/H

|

4 KW

|

150 kg

|

|

|

SRS-110

|

200-300 KG/H

|

7.5 KW

|

175 kg

|

|

|

SRS-130

|

300-500 KG/H

|

11 KW

|

285 kg

|

|

|

SRS-180

|

500-1000 KG/H

|

22 KW

|

340 kg

|

|

|

SRS-240

|

1000-2000 KG/H

|

45 KW

|

1300 kg

|

|

Item

|

Capacity

|

Model

|

Motor power

|

Weight

|

|

|

12 kg/h

|

6YZ-150

|

0.75 KW

|

240 KG

|

|

|

20 kg/h

|

6YZ-180

|

0.75 KW

|

550 KG

|

|

|

40 kg/h

|

6YZ-230

|

1.5 KW

|

950 KG

|

|

|

60 kg/h

|

6YZ-260

|

1.5 KW

|

1200 KG

|

|

|

70 kg/h

|

6YZ-320

|

2.2 KW

|

1700 KG

|

|

|

90 kg/h

|

6YZ-360

|

2.2 KW

|

2200 KG

|

|

Item

|

Capacity

|

Model

|

Motor power

|

Weight

|

|

|

20-150 KG/H

|

SRS-20B

|

4 KW

|

200 KG

|

|

|

80-200 KG/H

|

SRS-30B

|

5.5 KW

|

300 KG

|

|

|

100-300 KG/H

|

SRS-30B

|

11 KW

|

400 KG

|

|

|

200-400 KG/H

|

SRS-40B

|

15 KW

|

500 KG

|

|

|

300-500 KG/H

|

SRS-60B

|

22 KW

|

600 KG

|

|

|

500-1000 KG/H

|

SRS-80B

|

37 KW

|

800 KG

|

|

Item

|

Model

|

Capacity

|

Grinding time

|

Weight

|

|

Refining Machine |

CJM-20

|

20L/batch

|

8-10 hours

|

295 kg

|

|

|

CJM-40

|

40L/batch

|

8-10 hours

|

365 kg

|

|

|

CJM-100

|

100L/batch

|

16-22 hours

|

1050 kg

|

|

|

CJM-500

|

500L/batch

|

16-22 hours

|

2600 kg

|

|

|

CJM-1000

|

1000L/batch

|

16-22 hours

|

3050 kg

|

|

|

CJM-2000

|

2000L/batch

|

16-22 hours

|

5350 kg

|

|

Item

|

Model

|

Capacity

|

Weight

|

Dimension

|

|

Moulding

Machine

|

JZJ-8

|

8 kg/batch

|

30 kg

|

560*600*550 mm

|

|

|

JZJ-15

|

15 kg/batch

|

40 kg

|

660*600*550 mm

|

|

|

JZJ-30

|

30 kg/batch

|

110 kg

|

1.02*0.74*1.31 m

|

|

|

JZJ-60

|

60 kg/batch

|

140 kg

|

1.3*0.88*1.42 m

|

Q1: What power do you use in your factory?-V,-Hz, 3 phase or single phase?

(Like 220 V , 50 Hz , single or 380 V, 50 Hz ,3 phase...etc)

Q2: Can I Put my Logo on the machine?

Yes, Sure .

Q3. How can I trust you for the first-time business?

We can supply the business license and certificates. if you still worry about our company,

Q2: Can I Put my Logo on the machine?

Yes, Sure .

Q3. How can I trust you for the first-time business?

We can supply the business license and certificates. if you still worry about our company,

we suggest using Alibaba trade assurance service for all transactions to protect your money

and ensure our service for you.

Q4. How can you ensure the machine's quality after we purchase the order?

Before delivery, we will produce the equipment according to the agreed requirements, and

Q4. How can you ensure the machine's quality after we purchase the order?

Before delivery, we will produce the equipment according to the agreed requirements, and

after production, we will provide detailed operating instructions, testing videos, certification

documents, etc. Alternatively, you can arrange a third-party inspector to do inspection and

give you report.

Q5: How about the after-sale service and guarantee period?

1. 18-month warranty period for whole machine except for human factors etc. and 18 months’

1. 18-month warranty period for whole machine except for human factors etc. and 18 months’

after-sale service starts from the date when you receive machine .

2. Consultation services for whole machine life, and 24 hours technical support by email or video on line.

3.English software, user manual and the installation & debugging by our experienced technicians.

2. Consultation services for whole machine life, and 24 hours technical support by email or video on line.

3.English software, user manual and the installation & debugging by our experienced technicians.

Hot Searches