- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1500*3000mm

-

Cutting Thickness:

-

0-8mm

-

Control Software:

-

YASKAWA/EMPOWER

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Durmark

-

Weight (KG):

-

1500 KG

-

Warranty of core components:

-

3 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

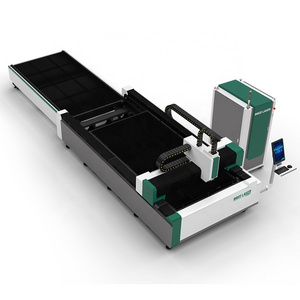

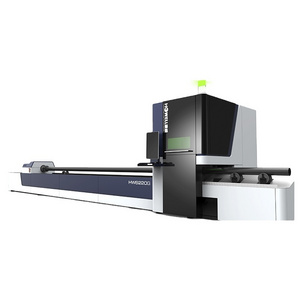

exchange platform sheet metal stainless fiber laser cutting machine

-

Cutting material:

-

Metal Stainless Steel Carbon Steel Aluminum

-

Servo motor:

-

YASKAWA

-

Certification:

-

ce ISO

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

1-8000mm/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1500*3000mm

-

Cutting Thickness:

-

0-8mm

-

Control Software:

-

YASKAWA/EMPOWER

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Durmark

-

Weight (KG):

-

1500 KG

-

Warranty of core components:

-

3 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

exchange platform sheet metal stainless fiber laser cutting machine

-

Cutting material:

-

Metal Stainless Steel Carbon Steel Aluminum

-

Servo motor:

-

YASKAWA

-

Certification:

-

ce ISO

Fiber laser cutting machine

Fiber laser cutting works by focusing the power of a high-power laser onto the surface of the material to be cut.

The energy in the laser beam is absorbed into the surface of material, and the energy of the laser is converted into heat, which melts or vaporizes the material.

Additionally, gas is focused or blown into the cutting region to expel or blow away the molten metal and vapor from the cutting path.

Choosing a Fiber laser cutting system will provide a number of advantages over traditional CO2 lasers, because of their high quality beam, Fiber lasers will allow you to cut, engrave and mark a wide range of metallic materials.

Our range of Fiber machines can be specified in a variety of power outputs ranging from 500W and up - which will provide you with a machine capability of cutting sheet metals such as 12 mm thick stainless steel depending on the machine power.

Watch video on YouTube

https://www.youtube.com/watch?v=lyzAqnWDqqA

Technical Parameter

|

NO

|

NAME

|

Value

|

Unit

|

|

1

|

Max. working area (length×width)

|

3000×1500

|

mm

|

|

2

|

X axis cutting length

|

1550

|

mm

|

|

3

|

Y axis cutting width

|

3050

|

mm

|

|

4

|

Z axis Lifting Distance

|

120

|

mm

|

|

5

|

X/Y axis positioning accuracy

|

0.05

|

mm/m

|

|

6

|

X,Y-axis repeated positioning accuracy

|

±0.02

|

mm

|

|

7

|

Maximum speed

|

90

|

m/min

|

|

8

|

Working Max. Acceleration Speed

|

0.5G

|

|

|

9

|

Total power protection grade

|

IP54

|

|

Main Features

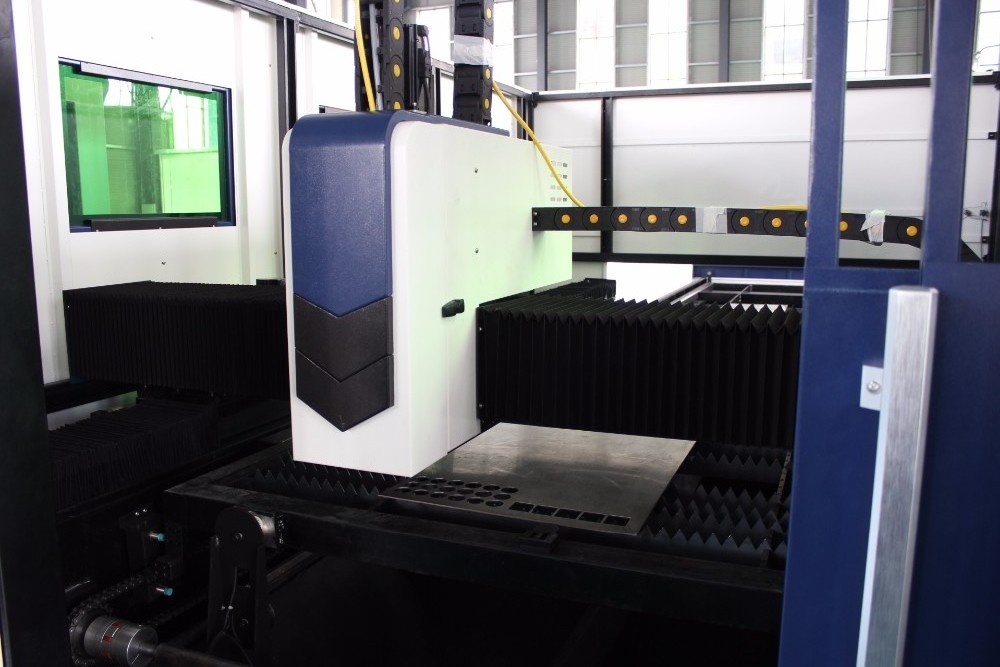

1. With dual-drive Gantry mechanisms, imported rack, pinion and linear guide for high speed steady transmission and high precision

2. Overall steel welding machine, rough machining after annealing.

3. Cooperated with vibration aging treatment to eliminate the stress of the welding and machining, maintained long term using without deformation.

4. Greatly improving the response speed and bed stability during working.

5. Japan imported servo motor for the X, Y, Z axis, high precision, high speed, high torque, large inertia, performance is stable and durable.

6. The servo motor combination ensure the machine's high speed and acceleration.

7. Based on the Windows operating system of fiber laser cutting machine CNC system, integrates a number of laser cutting control specific modules for better function.

8. Best human-computer interface, easy to operate.

9. With U. S. Lasermech produced special cutting head, and capacitive sensing, high precision induction and responsive for the most stable and reliable performance.

Typical Fiber Laser Cutting Applications

Precision engineering.

High precision sheet metal profiling.

Cutting metallic and non-metallic products.

Marking components for tractability, serial no. plates, ID plaques, VIN Numbers.

Industry Sectors Applied to

Medical

Automotive

Aerospace

Aviation

Marine Engineering

General Manufacturing

Pre-Sales Service

*Inquiry and consulting support

*Sample testing support

*Recommend the most suitable machine according to customer's purpose

*Factory visiting welcomed

After-Sales Service

*Training how to install the machine

*Training how to use the machine

*Warranty 1 year

*Engineers available to service machinery oversea

1. How about your machine quality? We are worry about the quality.

RE: DURMARK is a mature brand in CHINA,through many years research in technology,our design including structure and detailed sercurity and precision has enhanced greatly,and can match all the CE standard or more strict standard.Our machines distribute worldwide to about 50 countries where there are metal plate industry ,there are Brillante machines.And where there are our machines,there are good reputation and terminal user satisfaction

2. Whether the machine price can be more discount?

RE: 1.DURMARK always provide high quality machine, with 10years experiences,our machine has enough qaulity standard to make sure the machine can work more than the real warranty period. In this way ,we will save a lot and think in advance for the clients.

RE: 2. Actually DURMARK also think about our price level,we are sure to provide quality=price and pice=quality ,the matched price and acceptable for the clients and durable for our machines. We welcome you negotiate with us and get a good satisfaction.

Click below image for more info.