- Product Details

- {{item.text}}

Quick Details

-

Power:

-

0.5Kw

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

4020*1650*2400mm

-

Materials:

-

Full stainless steel

-

Various Heating Source:

-

Electricity, gas, diesel, coal, wood, biomass

-

Usage:

-

Frying Processing Line

-

Function:

-

Chips Deep Fryer

-

Material:

-

304 Stainless Steel

-

Keyword:

-

Restaurant Deep Fryer

-

Feature:

-

Fast Temperature Rising

-

Energy:

-

Natural Gas

-

MOQ:

-

1set

-

After Warranty Service:

-

Field maintenance and repair service

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LT

-

Voltage:

-

220V/380V

-

Power:

-

0.5Kw

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

4020*1650*2400mm

-

Materials:

-

Full stainless steel

-

Various Heating Source:

-

Electricity, gas, diesel, coal, wood, biomass

-

Usage:

-

Frying Processing Line

-

Function:

-

Chips Deep Fryer

-

Material:

-

304 Stainless Steel

-

Keyword:

-

Restaurant Deep Fryer

-

Feature:

-

Fast Temperature Rising

-

Energy:

-

Natural Gas

-

MOQ:

-

1set

-

After Warranty Service:

-

Field maintenance and repair service

Products Description

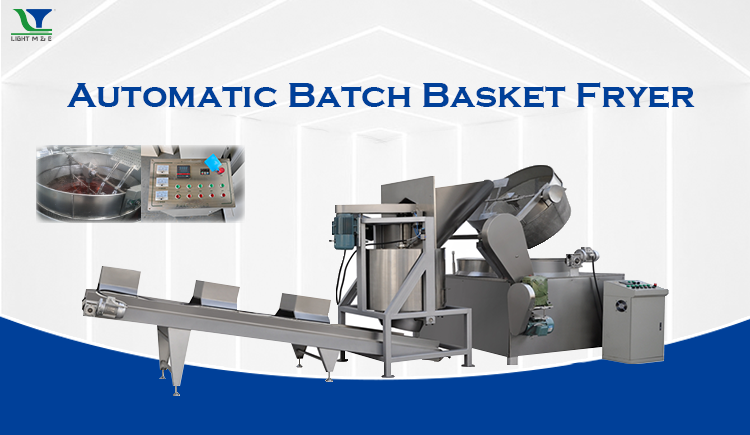

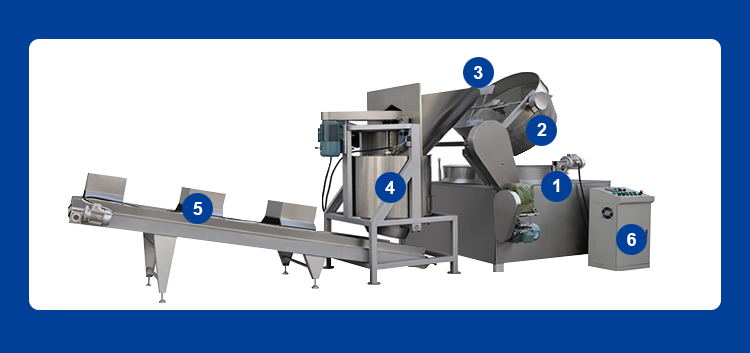

Batch basket Fryer

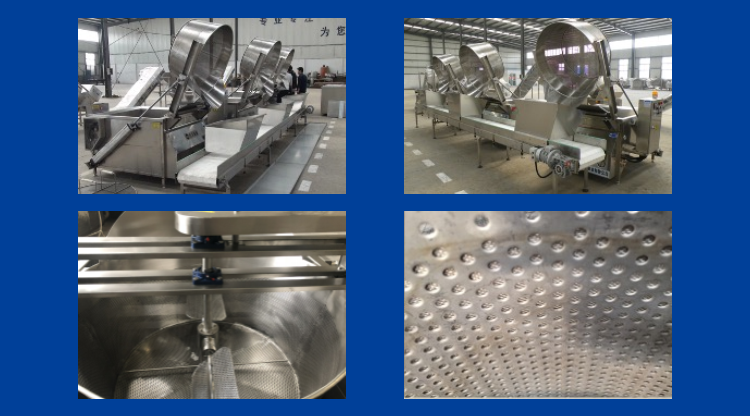

1.Equipment material: the whole machine is made of stainless steel SUS304

2.Control system: LCD touch screen;

3. The oil temperature can be adjusted from 0 to 400 degrees Celsius, and the set temperature and actual temperature are ±2

degrees Celsius; temperature detection probes are arranged in the oil tank, and temperature detection probes are arranged in

the circulation pipe:

4. Lifting method: the frying basket can be lifted automatically to meet the smoothness of feeding

5. Safety requirements:

1) The equipment is equipped with an emergency stop button at your fingertips;

2) The dangerous parts and areas of the equipment must have safety warning signs.

3) Equipped with standard working lights and equipment failure alarm devices, alarm history records can be checked;

3. The oil temperature can be adjusted from 0 to 400 degrees Celsius, and the set temperature and actual temperature are ±2

degrees Celsius; temperature detection probes are arranged in the oil tank, and temperature detection probes are arranged in

the circulation pipe:

4. Lifting method: the frying basket can be lifted automatically to meet the smoothness of feeding

5. Safety requirements:

1) The equipment is equipped with an emergency stop button at your fingertips;

2) The dangerous parts and areas of the equipment must have safety warning signs.

3) Equipped with standard working lights and equipment failure alarm devices, alarm history records can be checked;

The automatic batch fryer consists of frying system, automatic elevating system, automatic de-oil system,automatic conveying and

cooling system and can finish fryer,mix,de-oil and convey automatically.

cooling system and can finish fryer,mix,de-oil and convey automatically.

PLC Controller

1. Equipment material: the whole machine is made of stainless steel SUS304

2. PLC full touch screen control

2. PLC full touch screen control

Filter

1.equipment with 1set filter screen

2.filter screen density: 40mu-60mu

3.we can supply 2 sets of filter screen replace, it needs to clean by manual every 3-4 hours. 10m3 per hour

4.continuous working, it will filtering the oil before it enter the heating boiler.

2.filter screen density: 40mu-60mu

3.we can supply 2 sets of filter screen replace, it needs to clean by manual every 3-4 hours. 10m3 per hour

4.continuous working, it will filtering the oil before it enter the heating boiler.

Size Information

|

Item

|

Contents

|

|

Equipment capacity

|

about 20~60kg/hour.

|

|

Equipment size

|

1500*1500* 1600mm (the pot edge is 1290mm away from the ground)

|

|

Oil tank size

|

1100* 450mm

|

|

Equipment oil capacity

|

450L; Revolution rotation agitator

|

|

Heating system

|

electric heating 60KW

|

|

Heat exchange capacity

|

200000kcal/hr according to customer requirements

|

|

Stirring system

|

6-8 rpm

|

|

Air pump requirements

|

(customer-provided) Compressed air demand: 0.2 m³/min

|

Sample Show

Fryer can use electricity, gas,diesel as power source and can be widely used to fry the meat, snacks, pellet,potato chips,

sticks, beans, nuts, peanuts etc.

sticks, beans, nuts, peanuts etc.

Our Company

We, Shandong Light M & E Co., Ltd are located in the famous industry city-Jinan city, capital of Shandong Province. We are professional manufacturer of food extruder and mainly deal with the manufacture, research and development of the inflating food machine. According to the clients’ different requirements, we could offer the whole complete processing line for all kinds of expanded snacks, corn flakes, nutrition powder, pet food and so on. Our technical assistance will help clients produce high quality products all the time. As a leading manufacturer of inflating food machinery, we are selling and marketing the machines to many countries in the world. We keep improving our machines and upgrading techniques to satisfy the requirements of all the clients. Depending on our rich experience and professional experts on the extruded food industry, we could offer the most suitable and complete program to assure that your investment will get biggest profit. Therefore, we have exported our machines to many countries in the world, such as Malaysia, Indonesia, Pakistan, Sri Lanka, Brazil, Europe, Australia, Africa, South America, North America etc., and attained good reputation from the clients. Some of them have become our agents in their area. We hope to hold long friendly business relationship with more clients all over the world in the future. Since the establishment of our company, we have always manufacturing our machines according to the authorized standards and , by

now ,we have got several certificates including CE.

now ,we have got several certificates including CE.

Hot Searches