- Product Details

- {{item.text}}

Quick Details

-

Dimensions:

-

6880*1500*1550mm

-

Use:

-

SMT SOLDER

-

Weight (KG):

-

2800 KG

-

After-sales Service:

-

Field maintenance and repair service

-

After-sales:

-

Field installation, commissioning and training

-

After-sales S:

-

Video technical support

-

After-sale:

-

Online support

-

Voltage:

-

380V

-

Weight:

-

1850KG

-

Certification:

-

CE&Rosh

Quick Details

-

Applicable Industries:

-

SMT

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GRANDSEED

-

Dimensions:

-

6880*1500*1550mm

-

Use:

-

SMT SOLDER

-

Weight (KG):

-

2800 KG

-

After-sales Service:

-

Field maintenance and repair service

-

After-sales:

-

Field installation, commissioning and training

-

After-sales S:

-

Video technical support

-

After-sale:

-

Online support

-

Voltage:

-

380V

-

Weight:

-

1850KG

-

Certification:

-

CE&Rosh

|

ITEM |

SPECIFICATION |

|

Control system |

PC + PLC |

|

Heating/cooling zone |

12up12down 24 heating zone, 2 cooling zone |

|

Heating zone length |

3550mm |

|

Temperature range |

Room temperature ~ 350 ℃ |

|

Temperature accuracy |

±1 ~ 2 ℃ |

|

3 points temperature difference |

±2 ℃ |

|

Cooling style |

Forced air cooling(axial flow air cooling system) |

|

PCB size |

( W ) 50 ~( W ) 400mm |

|

PCB conveying height |

900±20mm |

|

Conveying method |

Chain track + belt conveyor |

|

Conveying direction |

left→right |

|

Conveying speed |

0 ~ 2000mm/min variable frequency adjustable |

|

Chain track widening range |

50 ~ 500mm |

|

Conveying belt width |

460mm |

|

Power-off protection |

UPS power supply |

|

Power supply |

A3ø380V 50HZ |

|

Normal operating power/total power |

8/93KW |

|

Dimension(L*W*H) |

6880 mm(L)*1500 mm(W)*1550 mm(H) |

|

Weight |

2800 KG |

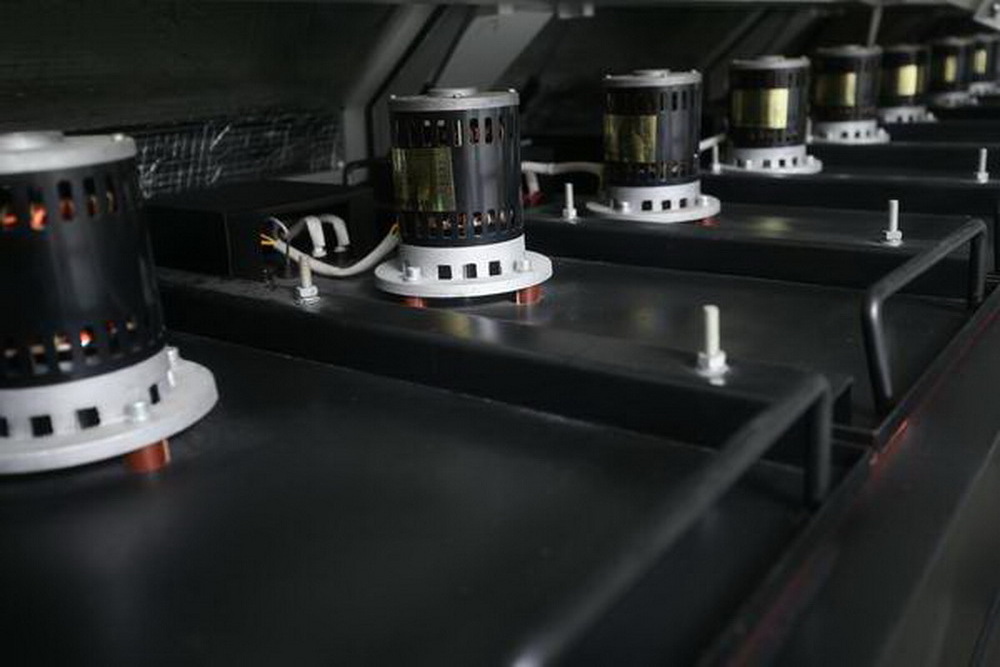

GSD-L12 features

- To extend the service life of the motor, our technical personnel specialize in design; Enable internal cooling circulation convection to lower the temperature around the motor to around 38 ℃ ;

- The high-temperature and high-speed motor operates smoothly with low vibration and low noise;

- Professional wind turbine design, stable wind speed, effectively preventing the uniformity of wind when PCB boards are heated, achieving high repeated heating;

- Each temperature zone adopts forced independent circulation, independent PID control, and independent heating mode from top to bottom, ensuring accurate and uniform furnace chamber temperature and large heat capacity; The heating method solves the problem of dead corners during reflow soldering. It is suitable for soldering electrical components such as CSP, BGA, 0201CHIP, etc;

- An online UPS equipped with power outage protection function ensures that the PCB board can output normally without damage after power outage;

- An independently controlled cooling system made of imported stainless steel, with upper and lower cooling convection. The cooled curve is mirrored with the welding temperature curve, fully complying with SMT international certification standards.

- The insulation layer adopts aluminum silicate insulation material, with a multi-layer insulation furnace design. The surface temperature of the outer shell of the furnace is about 5 degrees higher than the ambient temperature, effectively reducing the working environment temperature. The insulation effect is good, and the temperature rises quickly, from room temperature to working temperature ≤ 20 minutes; Special furnace liner design, low power consumption.