Feed Pellet Crumbler is the professional double roller crusher equipment use to break (Φ3.0~Φ8.0 mm) big size or diameter feed

pellet or grain feed into (Φ1.5~Φ2.5mm) small particles feed,use to fed 1-10days small chick baby. It can also directly crush

soybean, corn and soft mineral materials.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Standard 380V,50HZ,3Phase

-

Dimension(L*W*H):

-

1.5*1*0.5

-

Weight:

-

550 kg

-

Warranty of core components:

-

1 years

-

Machine material:

-

Stainless stell roller

-

Wearing Parts:

-

Hammer and Screen

-

Using for:

-

chicken feed production

-

Application:

-

feed crumble machine

-

color:

-

Customers' Requirement

-

Principle:

-

Double roller press

-

The Shell:

-

Carbon steel

Quick Details

-

Max. Capacity:

-

100 Set/Sets per mouth

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Double Crane

-

Voltage:

-

Standard 380V,50HZ,3Phase

-

Dimension(L*W*H):

-

1.5*1*0.5

-

Weight:

-

550 kg

-

Warranty of core components:

-

1 years

-

Machine material:

-

Stainless stell roller

-

Wearing Parts:

-

Hammer and Screen

-

Using for:

-

chicken feed production

-

Application:

-

feed crumble machine

-

color:

-

Customers' Requirement

-

Principle:

-

Double roller press

-

The Shell:

-

Carbon steel

Product Description

Double Crane Brand

SSLG Series Poultry Feed Pellet Crumbler Brief Introduction:

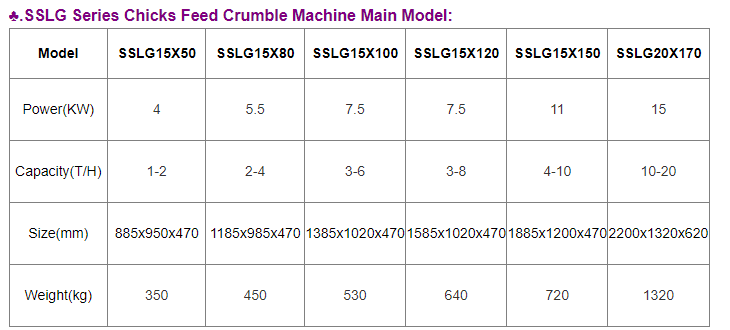

Specification

Why Produce Poultry Chicken Feed Pellet Need Use Feed Pellet Crumbler :

In the production of feed pellet,the first step is use feed pellet mill produce big diameter and size feed pellet, then use pellet crumbler break the pellet into small particles,this production method not only save the electric power and other resources, it also can improve final pellet production capacity,so it is the first choice for many feed manufacturers granulating process.

If not use pellet mill directly produce small size feed pellet for little chick baby,we must change small size/aperture ring die

in the pellet machine,the feed pellet production capacity will very low and have much more electricity comsumption.

If not use pellet mill directly produce small size feed pellet for little chick baby,we must change small size/aperture ring die

in the pellet machine,the feed pellet production capacity will very low and have much more electricity comsumption.

The crumbler produces crumbled feed to control reduction to a specific particle size with a minimum of fines. It's a roller mill with rolls specially designed for crumbling feed pellets, as well as in the flour milling and oilseed processing.

crumbler is a very solid machine, that allows to obtain a very homogeneous and regular granulometry of crumbled

pellet. The cutting rollers are adjustable and spring-mounted to protect against damage which could be caused by foreign objects.

crumbler is a very solid machine, that allows to obtain a very homogeneous and regular granulometry of crumbled

pellet. The cutting rollers are adjustable and spring-mounted to protect against damage which could be caused by foreign objects.

Packing & Delivery

Hot Searches