- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HTX-236

-

Product Name:

-

concrete fence mold

-

Application:

-

street pavement, walkway paving, villa, park, garden decoration

-

Feature:

-

not losing shape

-

Type:

-

concrete artificial stone wall panels molds

-

Lifetime:

-

more than 800 times

-

Certification:

-

ISO9001

-

Size:

-

Customized Size

-

Operation:

-

very easy,can make tiles by yourself

-

Color:

-

Customized Colors

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HTX

-

Model Number:

-

HTX-236

-

Product Name:

-

concrete fence mold

-

Application:

-

street pavement, walkway paving, villa, park, garden decoration

-

Feature:

-

not losing shape

-

Type:

-

concrete artificial stone wall panels molds

-

Lifetime:

-

more than 800 times

-

Certification:

-

ISO9001

-

Size:

-

Customized Size

-

Operation:

-

very easy,can make tiles by yourself

-

Color:

-

Customized Colors

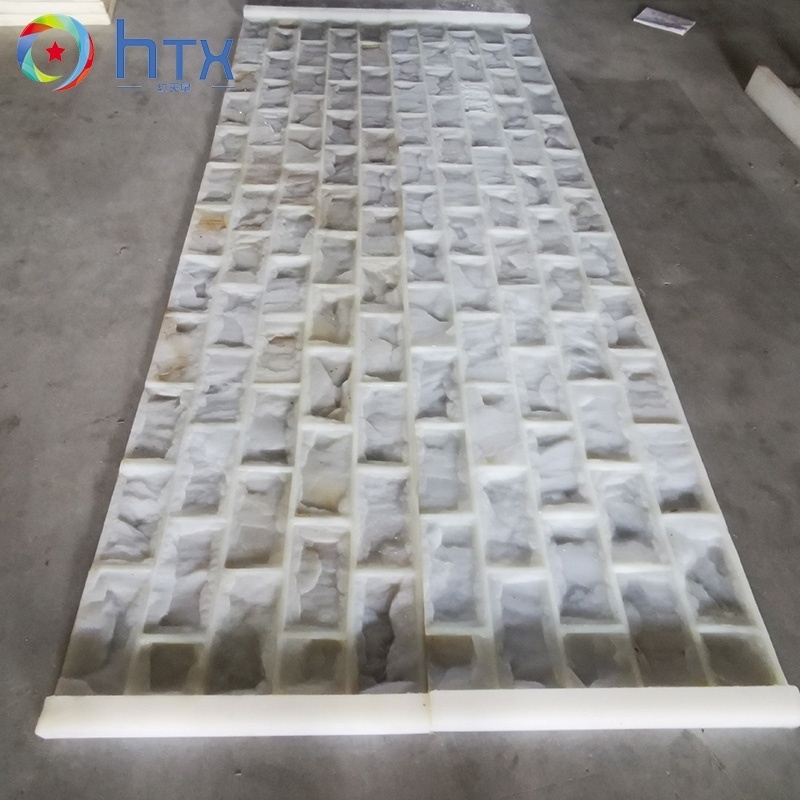

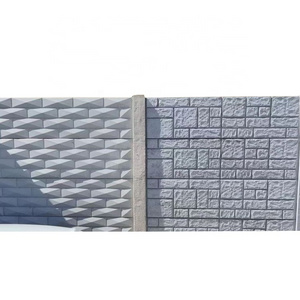

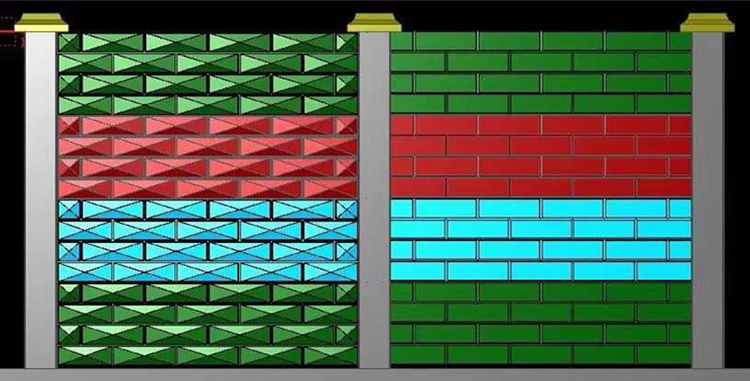

concrete post mould precast Courtyard garden concrete wall stone fence plastic mold

It is estimated that by 2021, the demand for concrete fence panels will grow at a rate of 5.3% per year, because many concrete fence panels are commonly used as internal or external privacy fences for single-family houses, apartments and even commercial buildings. This investment is very meaningful when concrete fence panels can withstand the harshest weather conditions and provide attractive functional barriers to attract people and animals.

| Faux Stone Privacy Fence Block wall mold Precast Concrete Fence Panels mould | |

| used as internal or external privacy fences for single-family houses, apartments and even commercial buildings. |

There are a number of reasons why homeowners choose to invest in concrete fence panels, but perhaps the largest reason for using concrete is that it can be designed and built to meet almost any individual’s needs. For instance, one of the main reasons that consumers choose to purchase a precast panel is that it offers a quick and easy installation and maintenance solution.

In addition to being easy to install, there is also a quick application process, which can take just a few hours to complete. Once the application is complete, all that is left to do is wait a day or so before the concrete fence panels are ready to be installed. This results in a low-cost investment and a quick return on your investment. Unlike a metal fence that requires costly and time-consuming fabrication, precast panels are made to measure with precast kits available from many manufacturers, including Trane, Loomis, Duro Contractors, and Torklift Concrete.

Because precast concrete fence panels are custom made, they are much easier to install than metal fences. There are no long and tedious cutting and shaping processes involved, so homeowners have the ability to create a highly professional looking enclosure in just a short period of time.

Concrete is an excellent material for fencing because it is durable and easy to maintain. Unlike wood, steel, or aluminum, it does not need to be painted or sealed and will stay looking new for many years. Because it is water-resistant, it also makes it easy to apply a sealant to keep insects, dust, debris, and rain out while maintaining its look and ability to keep animals and people out.

Precast fence panels are also a great choice for homeowners who have limited budgets. By installing a precast fence, you can design a home that can be erected quickly and easily, yet remain durable and beautiful for many years to come. This makes it an excellent choice for home enclosures on vacation homes, for commercial buildings, condominiums, or commercial buildings where large outdoor spaces are needed for offices, storage, and even for schools and churches.

Because precast concrete fence panels are easy to install and maintain, homeowners may also save money by using them for commercial buildings. Rather than having to hire a contractor to create a custom-made metal or plastic fence, they can save money by simply purchasing a precast panel in precast kit form and then installing it themselves.

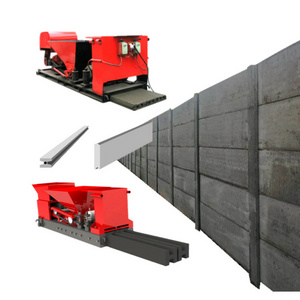

During installation, the column is pre-embedded with 500mm, and the exposed ground is 2000mm; 4 wall panels, 2 columns and 2 column caps form a whole wall assembly combination.

The overall composition of the mould: 1 wall panel mould + one column mould + 1 column cap mould;