- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2000mm*5000mm

-

Year:

-

2020

-

Power (kW):

-

20 kW

-

Weight (KG):

-

20000 KG

-

Applicable Industries:

-

waste recycling

-

Function:

-

machinary plastic convert to oil

-

Machine Type:

-

Batch Working

-

Operation:

-

2-4 Persons

-

Operating Pressure:

-

Normal pressure

-

Structural form:

-

Horizontal Rotation

-

Raw material:

-

Waste Tyre Waste Plastic

-

End product:

-

Fuel Oil Steel Carbon Back

-

Advantage:

-

Environmental Friendly

-

Heating fuel:

-

Wood Coal Gas Oil

-

Material of reactor:

-

Q245R/Q345R Boiler Steel

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

zhongyu

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2000mm*5000mm

-

Year:

-

2020

-

Power (kW):

-

20 kW

-

Weight (KG):

-

20000 KG

-

Applicable Industries:

-

waste recycling

-

Function:

-

machinary plastic convert to oil

-

Machine Type:

-

Batch Working

-

Operation:

-

2-4 Persons

-

Operating Pressure:

-

Normal pressure

-

Structural form:

-

Horizontal Rotation

-

Raw material:

-

Waste Tyre Waste Plastic

-

End product:

-

Fuel Oil Steel Carbon Back

-

Advantage:

-

Environmental Friendly

-

Heating fuel:

-

Wood Coal Gas Oil

-

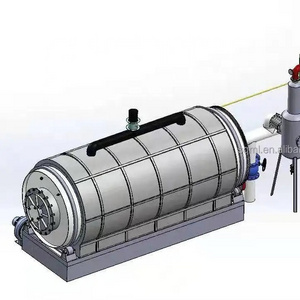

Material of reactor:

-

Q245R/Q345R Boiler Steel

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE ISO

Product Description

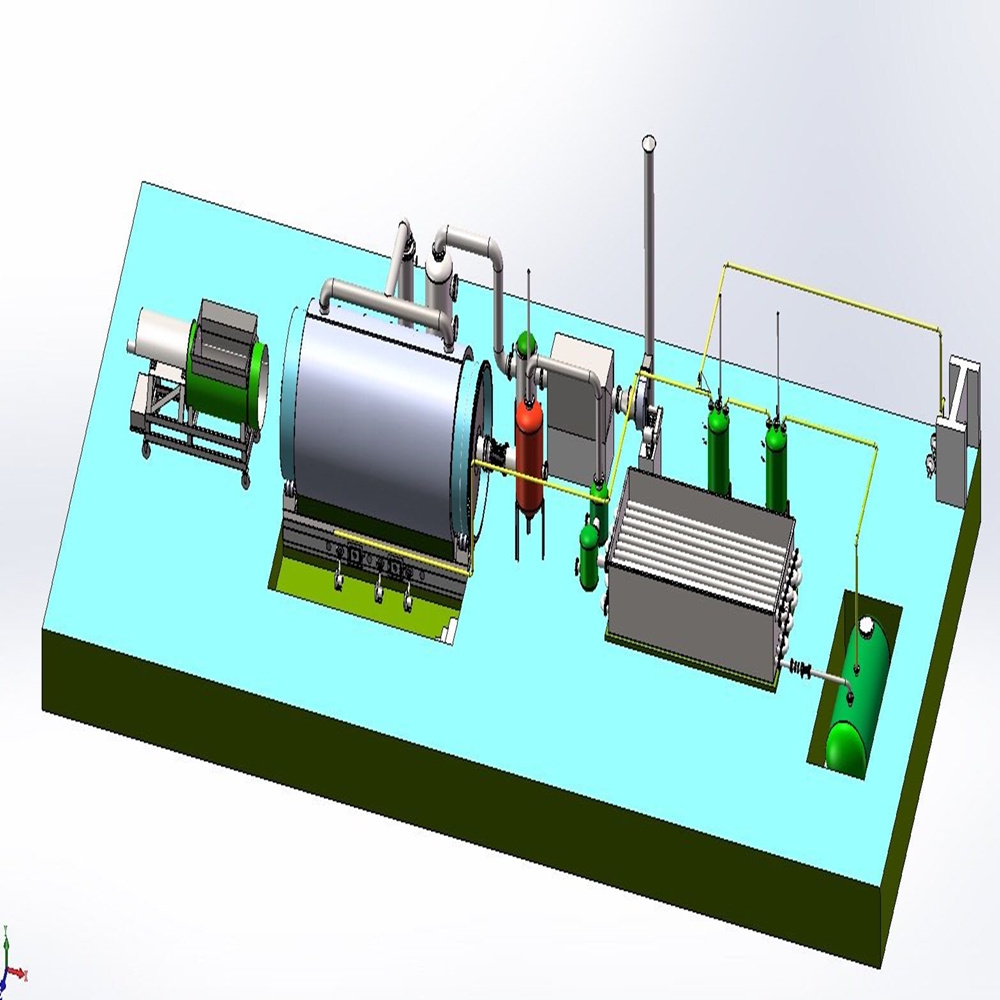

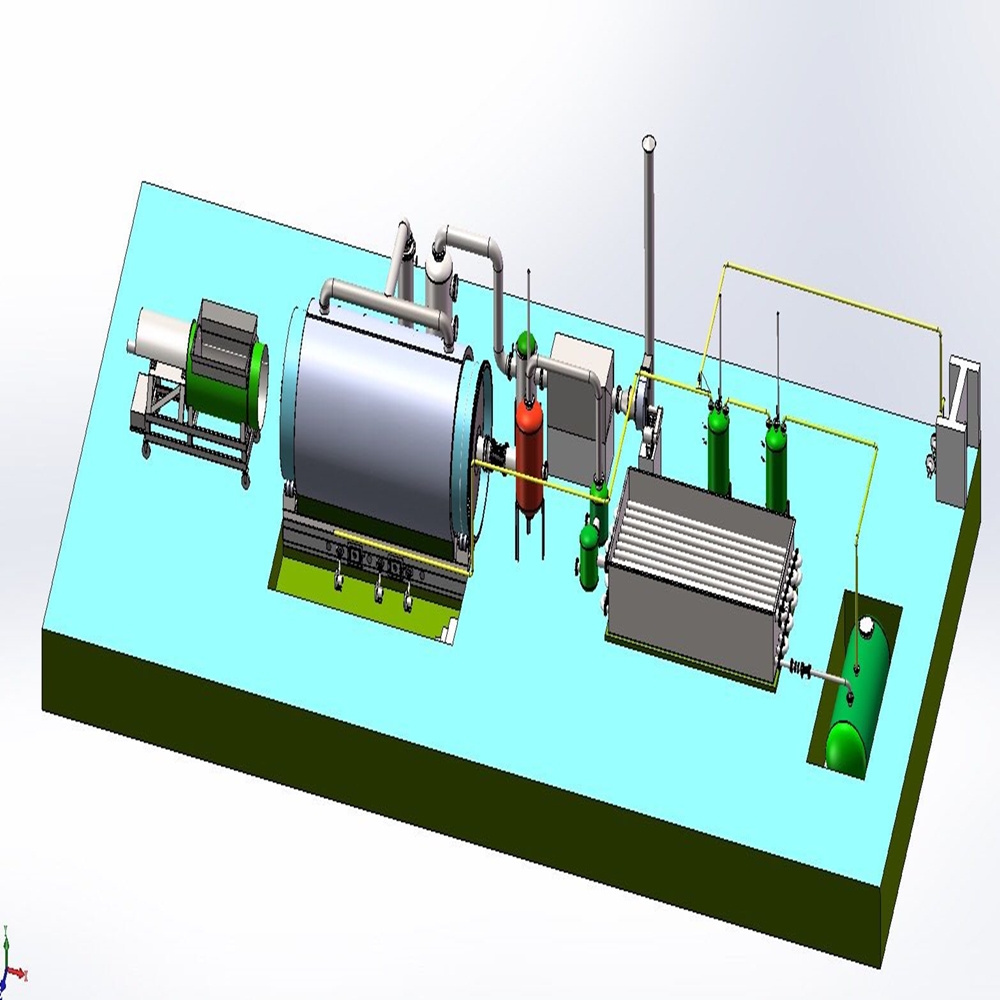

The pyrolysis of waste tires/rubber/plastics/solid waste/waste oil is a well-known method to minimize the environmental impact.

The pyrolysis of waste tires/rubber/plastics/solid waste/waste oil can be described as the chemical process and thermal decomposition of organic components in an oxygen-free atmosphere to produce charcoal, oil and gas.

The pyrolysis of waste tires/rubber/plastics/solid waste/waste oil is an endothermic process, so it needs to provide heat.

Thermal decomposition of convective plastics has been operating on an industrial scale worldwide.

Project details of the new business concept for the pyrolysis oil distillery

1. 10 tons of oil refining equipment per day.

2. The whole machine includes a distillation reactor, a fractionation tower, a condensation part, a dust removal part, and a color and odor removal device.

3. The input raw materials can be crude oil, pyrolysis oil, sludge, waste engine oil, dirty black oil, waste tires/rubber/plastics/solid garbage/waste oil.

4. The output product is clean synthetic diesel.

5. High degree of automation, high degree of intelligence, no pollution

6. The heating fuel can be coal, wood, pyrolysis oil, and natural gas

Specification

|

Item

|

Contents

|

|

Input-Raw Materials

|

Waste tire/rubber/Medical waste/MSW

|

|

By-products

|

Waste tires/rubber/medical waste/domestic waste/crude oil/pyrolysis oil/sludge/waste engine oil/dirty black oil//plastic/solid waste/waste oil

|

|

Model

|

Reactor size

|

|

|

2200*5500

|

|

|

ZY2200*7500

|

|

|

ZY2600*6600

|

|

|

ZY2800*6000

|

|

|

ZY2800*6600

|

|

Reactor material

|

Q345R/Q245R/310S+Boiler plate/Stainless steel

|

|

Thickness

|

14mm/16mm/18mm

|

|

Weight

|

15T-35T

|

|

Power

|

Average 15KW/h

|

|

Space needed

|

300-400 square meters (Width:10m, Length:30m-40m)

|

|

Labor needed

|

3-4 workers

|

|

Density of oil

|

0.89g/cm3

|

|

Combustion value

|

44.30KJ/KG

|

|

Note:

|

We supply customized mini plant: 10kg plant, 1ton plant for customer trial operation.

|

|

Item

|

Function

|

|

Distilation reactor

|

The waste oil will be pumped into the reactor for refining.

|

|

Distillation column

|

Atmospheric Fractionator Ensure differrent Fraction come Out.

|

|

Condensing device

|

The oil gas will be cooled to liquid oil then flow to the oil storage tank

|

|

Vacuum pump

|

Ensure the distillation machine working under normal pressure.

|

|

Anti back fire device

|

Safety device , prevent the oil gas revert to the reactor.

|

|

Non condensable oil gas recycling system

|

The non condensed oil gas (Syngas ) will be recycled to heating system as fuel.

|

|

Color and smell removal system

|

the last step to remove bad smell and color to yellow diesel oil.

|

|

Dedust system

|

3 layers of ceramic packing dedusting to remove dust and acidity, non- pollution.

|

|

Safety devices

|

Auto releasing pressure device , alarm, safety valve , etc to ensure safety operating.

|

|

Items

|

Application

|

|

50% Pyrolysis oil (tire oil/plastic oil)

|

1. Add it into heavy oil generator to produce electricity.

|

|

|

2. Used as heating material.

|

|

|

3. Sell it into oil refining factory to further process it.

|

|

25%-30% Carbon black

|

1. Make it into pellet or briquette for burning.

|

|

|

2. Further process it into color master batch as basic material to make pipes, cable jacket…etc.

|

|

10% Waste gas

|

Recycled into fire furnace to heat reactor to save fuel material.

|

Collecting oil from the distillation machine , The yellow color oil is diesel oil after remove color and smell.

a) Safety

1) Two devices to avoid backfire in production: oil-water separator and anti-back fire device.

2) Vacuum device makes reactor working under ordinary pressure or negative pressure.

3) Temperature monitoring device to avoid excessive working temperature.

4) Pressure gage to monitor the pressure. If it goes above a certain level, the bell will alarm and the safety valve will release the pressure automatically.

5) Carbon black is discharged in a closed situation to avoid catching fire.

b) Environmental protection

1) The flue gas (caused by burning fuel to heat the reactor) will be purified and cooled by dust removal device, then can be released into air through chimney.

2) The procedure to remove carbon black is working under closed situation to avoid pollution.

c) High oil yield

1) We have 3 steps for cooling system: one condenser pipe, two large horizontal condensers and two vertical condensers. The oil gas pass through 3 steps cooling system in sequence. The total cooling area is 65 square meter.

2) When the oil gas pass through the condensers, it’s divided into several portions by small pipes inside condenser and be cooled separately.

3) In this way we maximize the cooling effect and improve the oil yield.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches