- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1250 kg

-

Quality authentication:

-

ISO9001:2008

-

Material for filter tank:

-

stainless steel,carbon steel,FRP

-

material for face piping:

-

stainless steel or PVC,carbon steel

-

Power supply:

-

AC380V 35A 50Hz,customized

-

working presssure:

-

0.6-1.6Mpa

-

Function:

-

Filtering Suspended Matter

-

Filter Media:

-

Sand+carbon

-

Feature:

-

Eco-Friendly Easy Operation

-

After-sales Service Provided:

-

Video Technical Support\Online Support

-

Pretreatment:

-

sand filter

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YLD

-

Productivity:

-

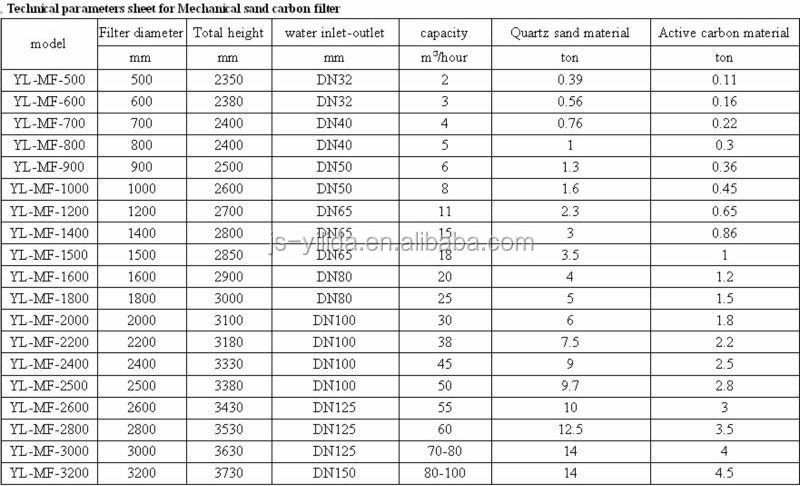

30000L/Hour

-

Weight (KG):

-

1250 kg

-

Quality authentication:

-

ISO9001:2008

-

Material for filter tank:

-

stainless steel,carbon steel,FRP

-

material for face piping:

-

stainless steel or PVC,carbon steel

-

Power supply:

-

AC380V 35A 50Hz,customized

-

working presssure:

-

0.6-1.6Mpa

-

Function:

-

Filtering Suspended Matter

-

Filter Media:

-

Sand+carbon

-

Feature:

-

Eco-Friendly Easy Operation

-

After-sales Service Provided:

-

Video Technical Support\Online Support

-

Pretreatment:

-

sand filter

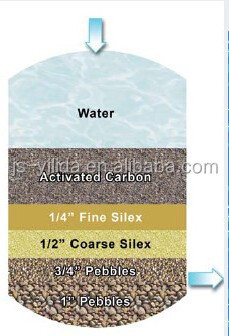

ressure vessels with sand or other loose media are widely used in industrial filtration applications. During the cleaning cycle, called "backwash", the bed is lifted (or "fluidized") to loosen the filter media and release trapped dirt which is removed in the backwash flow. After the backwash cycle, the bed is allowed to settle before the filter is returned to service (i.e., normal flow). A "filter-to-waste" cycle is used following the settling to assure the filtration media has sufficiently restratified and that any loose dirt is removed from the underdrain / collectors.

Multimedia filtration refers to a pressure filter vessel which utilizes three or more different media as opposed to a "sand filter" that typically uses one grade of sand alone as the filtration media. In a single media filter, during the "settling" cycle, the finest or smallest media particles remain on top of the media bed while the larger, and heavier particles, stratify proportional to their mass lower in the filter. This results in very limited use of the media depth since virtually all filterable particles are trapped at the very top of the filter bed or within 1-2 inches of the top where the filter media particles have the least space between them. The filter run times are thus very short before the filter "blinds" or develops so much head pressure that it must be backwashed to avoid seriously impeding or stopping the flow.

When the system is in a filtered State, the water flow through the water distributor which was unallowed,comply with shell,the water flow through the filter layer at the horizontal - flow state,as the water flowthe filter material layer, impurities are trapped within the filter layer,The filtered water is collected and evenly through water outflow,flowing parallel,at the high speed ,the filter could work well,and it can reach better effect too.

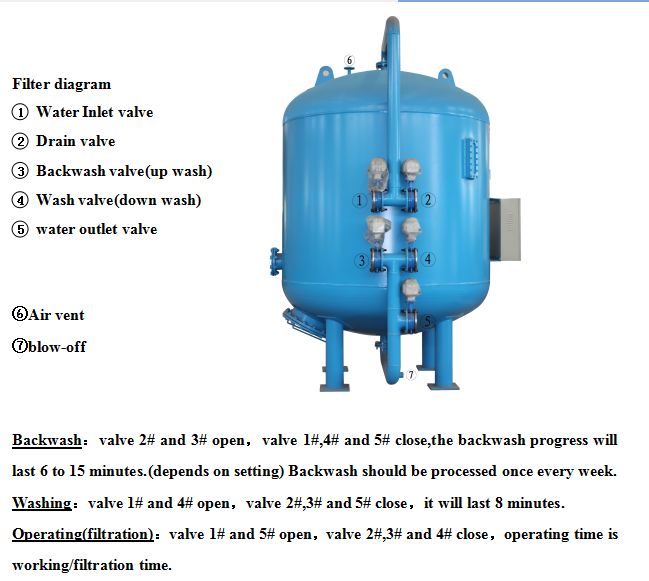

Backwash

With the continued accumulation of impurities in filter material layers, increasing loss of head,as the loss of head reaches a certain set limit, system will automatically be converted to the anti - washing, cleaning accumulation of impurities,

Backwashing happens at the differential pressure reaches 0. 05-0. 07Mpa,each time.and while the backwashing is over the differential pressure will back to 0.02-0.03Mpa.