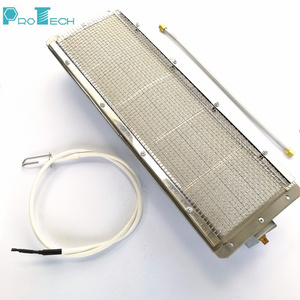

I

NFRACAT catalytic infrared radiation panel;

Suitable for clean gas fuels such as natural gas and liquefied gas;

Radiation panel surface temperature adjustment range: 180°C to 550°C;

Radiant panel can be designed according to requirements, heating power: 1.5kW to 17kW;

Products comply with CE certification, FM certification, ATEX explosion-proof certification, EAC certification, etc.

The achievable design power is: 20kW/m²